How to get closer towards Industry 4.0?

Vol.2/3: Take the first steps on your way to Smart Factory in AWS – achieve the first value

The best way to ensure business growth in the digital age is to harness the potential of new technologies. For this purpose, top business leaders are using digital transformation to find new opportunities, business models, make changes in their organization and bring new level of value to them. Most of them are aware of the challenges associated with such a colossal change in an organization.

The main challenges faced by organizations on their journey towards Smart Factory are:

Companies tend to face obstacles that include employees’ reluctance and their concerns about changing the status quo (or about the fact that they will be eventually replaced by technology), a lack of a sufficiently experienced in-house IT, or a poor plan to implement the necessary changes. Reinforcing your digital adoption strategy, supported by the right cloud strategy, gives you the chance to achieve the expected return on investment.

Before we move on, let’s start with a short summary of the first article on Smart Factory (in AWS). We presented a big picture of this idea, its origin and importance in today’s fast-changing world. Then, you could learn how to approach digital transformation, how to start the Industry 4.0 journey. Digital transformation is also a change in the organization that needs to be prepared for. And following best practices, we advised to do so in small steps. What you should do is start from analysis and ROI of your business assumptions of the first business case, then implement them and enjoy all the benefits of accomplishing the first MVP (Minimal Viable Product). All steps should follow the Smart Factory roadmap.

Now, equipped with basic knowledge, you are ready to safely get on your way. Have no fear; we will guide you all the way.

For those who didn’t have a chance or missed the first introductory article on the subject, feel free to read First Steps with Smart Factory before reading the second article.

Prepare your organization for the inevitable changes

Introducing digital transformation is not only beneficial, but necessary to confront disruption and be competitive. But in order for change to be beneficial, you need to get ready for it – and that includes preparing your employees for what may come.

Before implementing a digital transformation roadmap, industry leaders should identify the key people roles required and build a team of experts.

In the area of strategy, the managers of industrial companies must assess their needs for the right people. Start by identifying gaps, then consider whether the roles are likely to be executed with proper employee training, or whether external specialists or partnerships should be acquired.

The organization will certainly need a new structure, and in some cases new roles will have to be created. You are also going to need a Project Manager to ensure that the company’s journey towards Industry 4.0 and Smart Factory, is profitable and smooth.

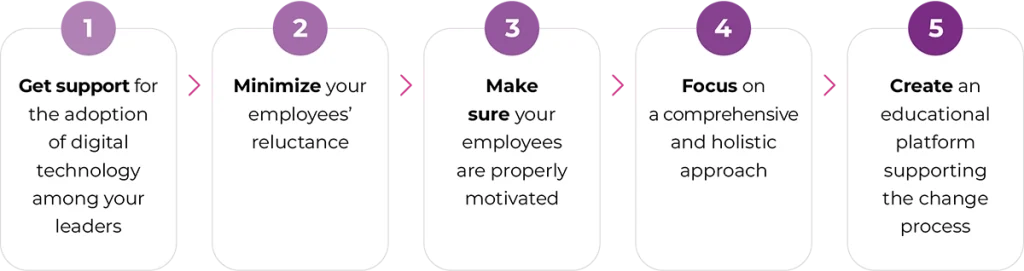

The main steps to prepare your workforce for digital transformation

The right approach to change management is critical to the success of any digital adoption plan. In fact,

helping employees throughout complex transformations is where the support of leaders will be extremely

beneficial.

Psychology proves that it is natural for people to be reluctant to change. Moving toward streamlining and

reengineering the organization in line with the idea of the Smart Factory causes enormous structural changes. If you don’t want to face an army of frustrated employees, provide them with support throughout the process; by communicating the need for change and a series of highly customized training sessions on dealing with the new systems. The importance of motivating employees to learn new work methods and supporting digital transformation cannot be overlooked either. The entire process should also be transparent, and all milestones should be communicated extensively within the organization.

Digital adoption strategies require a comprehensive and holistic approach. By limiting ourselves to transforming only selected business areas on the path to digital transformation, we risk future problems that could have been avoided. This can even lead to a halt in the transformation process. Therefore, the digital implementation strategy should cover the entire organization without exception. This approach also makes it easier to track the progress of digital adaptation.

Employees should be encouraged to learn new things and this needs to be facilitated. One way to do this is to create a platform that guides the employee by the hand through the entire learning process. This is also a way to get meaningful feedback so that leaders can make necessary changes to the process.

Identifying and prioritizing use cases and getting ready for implementation

Anyone who has had the opportunity to work in an agile model knows that the basket of user stories can be bottomless. However, not all of them will make it to the backlog, as they are not always feasible or will bring measurable benefits.

Likewise with the set of identified business cases that emerged during work with the roadmap. Some of them are more important than others (the need for prioritization), some should be dropped from the agenda because in the light of today’s technical possibilities they are not feasible. And some have no business justification and will not bring the expected benefits. This right analysis is extremely important if we don’t want stuck in the pilot phase.

With the list of prioritized and important business cases, we can proceed with the implementation process, but before that, we should determine the key stakeholders, their responsibilities and importance in the whole process.

Gather all stakeholders at one table

Digital transformation of an organization should be treated as a huge project that involves many experts and affects all areas of the organization. In order for the project to be successful, management guidelines must be followed in the areas of communication, monitoring and best implementation practices. The implementation project, just like the pilot, must be developed in consultation with all stakeholders who participate in or are affected by the implementation activities. It is essential to educate them on the purpose and importance of the project to the entire organization, and to get their support.

Communication is key here, as the project usually involves not only members of one team, but also employees from various departments or external representatives of partners. In many cases, we need experts we do not have in-house, so in this case even the help of the HR department will be indispensable.

There are three areas where common agreement is essential for successful implementation:

- At the very beginning, before starting the project, consultation with IT specialists is required to assess security requirements, capacity of the existing network or to create a proper cloud adoption or modernization strategy, also keeping in mind the possibility to easily add new functionalities in the future.

- Data management refers to the management and storage of data. It describes the rules regarding who has access to which data and how. To ensure smooth communication and collaboration, it is logical for all stakeholders to have access to the necessary data. The level of access to this data is approved by in-house IT.

- A project of this scale is bound to affect the operation of the entire organization. There are legitimate concerns about the capacity of the IT network, which at the same time must efficiently support Manufacturing Execution systems (MES) or Enterprise Resource Planning (ERP) applications. A manufacturing organization requires consultation in this area so that the parallel implementation of the Industry 4.0 project does not negatively affect the efficiency and safety of current production.

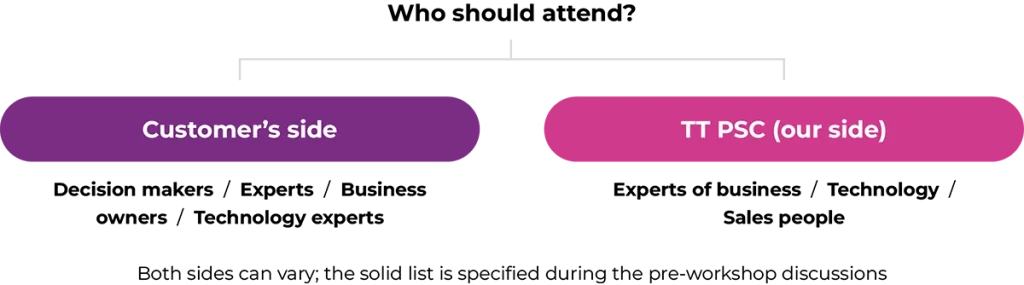

Who is needed for a successful digital transition process?

A very first step of digitalization journey:

Working with the roadmap

Once the decision is made to follow the path of digitization with us, we advise you to start with the joint Discovery Workshop (DW). We are ready to help from the very beginning. At the DW, our business and technical experts help you find the right way to explore the potential and benefits of the Internet of Things. These workshops serve as a basis for further roadmap analysis and planning. We will try to discover possible improvements and find the best path for the client to Industry 4.0. We will listen to your pain points and everyday problems, and learn more about the intricacies of your business field.

The outcome of this DW will be a clear vision of expectations and opportunities on both sides. We will then present a summary with key findings, suggested next steps, possible timelines – a general roadmap with a digitalization plan. It is not final and will be subject to review, changes and adjustments during our cooperation. One of the key points is the suggestion for short-term exposure to the organization’s operation, which will allow us to get started quickly with Proof of Value. We will present the suggestion for the first, short-term participation at the end of the DW or shortly after in the wrap-up. During the first PoV (Proof of Value), the project with the highest possible ROI should be implemented.

At the end of the PoV, we will get results on the goals achieved. This will give us a clear vision of what goals are being achieved and how we can take advantage of further opportunities to deliver the best value. An important fact is that the analysis of PoV results should consider both financial and non-financial benefits.

Now imagine that we are at the point where we have managed to successfully launch the first MVP based on the first business case. We can verify the hypotheses we made earlier and find answers to the question: does this minimal solution solve our problems and achieve our goals? Remember that the first MVP is rarely perfect – it may lack features that will be implemented in the next stages, and may have shortcomings, but it is enough to check if our organization is ready for the digital journey towards Industry 4.0 and if a particular case is capable of delivering the expected business results.

A successful digital transformation is a state in which the implementation of all technologies brings the intended business value. This means that your employees support the changes made and fully benefit of the opportunities provided by new technologies.

Nowadays, every company is benefiting to some extent from the technological advances of the new era. The integration of these solutions to make them work as a whole usually becomes problematic. However, the goal of digital transformation and implementation of Smart Factory idea, and thus integration of all technological solutions used in an organization, should always be driven by the achievement of a positive return on investment (ROI).

Starting the digital transformation before determining the whole process is like a journey without a map. The result is obvious – 99.99% of the time you will get lost, and in the end, it will cost you more. To avoid this fate, you need to have a clear plan consisting of a thorough analysis of the possibilities and the preparation of a unique roadmap adapted to the organization’s situation.

The first step to leveraging the benefits of digital transformation is to create a digital organization strategy (the first stage of a roadmap presented in First Steps with Smart Factory). This includes analyzing the company’s capabilities, estimating the resources required, considering potential (technological) partnerships that could help achieve the goal, identifying all business pain points and problems, and defining the expected results and the final goals. At this stage, we should consider what we have learned from the implementation of the first Business Case to prepare an Industrialization plan before launching the Production Pilot.

A feasibility study of the proposed initiatives and an assessment of the potential value to the organization should also be made. This is a plan for an agile and iterative implementation stage. The question that needs to be answered here is: how can the implementation of the Industry 4.0 idea help improve organizational performance, create opportunities for a new value chain and discover new business models?

For the Connectivity area, we should determine the way of connecting all devices and machines to each other and to the central system – and how to make them intelligent, e.g., by using edge capabilities and gateways. The starting point of the analysis will be the current IT infrastructure. A dedicated infrastructure should be planned, including one based on AWS cloud or a hybrid solution. Integration includes assessing the needs and opportunities for integration between the IT and OT layers.

We need to remember that the biggest value in such initiatives is usually behind the monetization of the

company’s data and the ability to take insights to drive operational efficiency. To achieve this, we use AI/ML. For the areas of Visualization and Descriptive Analytics, as well as Artificial Intelligence, we determine how and from what sources we will obtain data, or whether it requires standardization. The challenges of processing massive amounts of data (Big Data) are surmountable thanks to the capabilities of AWS cloud. Good planning in this area will allow us to obtain unified and comprehensive data from across the enterprise. Which will allow us, once the Industry 4.0 is implemented, to detect inaccuracies or bottlenecks, or to react more quickly to signals of threats that could even result in production stops. AWS AI combined with IoT will enable predictive maintenance of machines, and this will translate into lower repair costs. AI-based Machine Learning algorithms allow us to detect trends in data and thus provide early warnings and clues about possible malfunctions.

Then we need to proceed with planning for the scaling stage, i.e., the implementation of digital transformation projects on an organization-wide scale. Not forgetting to anticipate future development needs as well.

Depending on the decision made, a pilot industrialization plan will be prepared to implement a full-scale production-ready version. This includes not only architectural and implementation changes, storage capacity (which are less relevant from the perspective of business users), but also the involvement of more real data sources (devices or machines), additional users and so on. This plan and analysis should suggest next steps and define the scope and objectives. Once the necessary changes have been made, a Pilot should be implemented for the extended (but not fully productive) scope/area.

Press the “implementation” button

At this stage, it is necessary to assign appropriate roles – people to individual tasks. Both on the side of the System Integrator, that is us , and on the side of the customer, and focus on the final goals.

Depending on the needs, you will need specialists in cloud (e.g., AWS), PLM, or combination of these two Worlds – PLM in the cloud; or IoT, as well as AR and Industrial Analytics to assist you throughout the entire journey. As a company with technology deeply rooted, we have all experienced people on board. From every field necessary for the digital transition of the company towards the Smart Factory too.

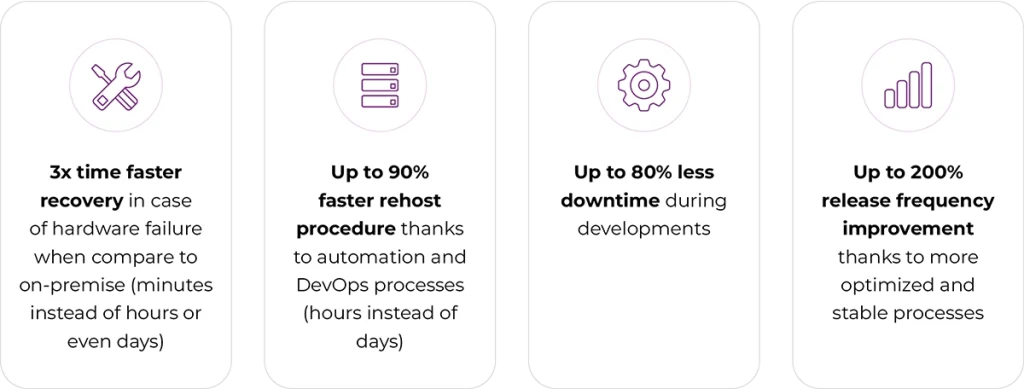

We know that facing the road of digital transformation alone is not easy. A key factor that will help you on this path is the use of cloud computing technology. Cloud technology gives you access to unlimited computing capacity, which will be helpful in the digital transformation of your organization. Moreover, it will also speed up your systems and reduce maintenance costs. Organizations are storing more and more IoT data in the cloud.

This brings financial, industry, security, privacy and local law challenges. Most of the restrains and obstacles fade if data is stored in the cloud. Long story short, the cloud vendor manages all the storage infrastructure requirements without changing the core logic of the IoT application.

These are the main reasons why a proper cloud migration strategy or cloud modernization is extremely important. Together with our experts, we offer an analysis of your business needs and identification of technical limitations. We also assess your organization’s maturity for cloud adoption and develop a plan for necessary upgrade (if your organization is already benefiting from the cloud). Keeping in mind that cloud services should serve the Smart Factory journey.

Why do you need cloud power for your Smart Factory journey?

Like most companies in the IT industry, we work using the Agile methodology. Why? Because it guarantees that at the end we will get the best and expected results of our efforts. In addition, at the beginning of the project, we will get the first working solution very quickly. This is also a chance, thanks to the brief feedback during the implementation of the first MVP, to gain the necessary expertise and match our plan to the reality and our goals.

MVP post-implementation workshops and support

After the implementation of the first MVP, we will run end-user Workshops to support your employees and keep up the momentum to achieve the set goals. The value of the implemented elements of the overall plan and their ROI will also be validated. It is essential to measure the impact of the solution on the business problems it is intended to solve.

This is the second article in the series. The last and third one, is planned to be released in about a month. We will cover in it topics such as adoption, scaling, and industrialization; implementing Industry 4.0 and Smart Factory, supported by the AWS cloud, in new factories; and exploring new use cases.

Goto 3rd article in this series: Smart Factory in AWS – scaling solutions for multiple factories