_About us

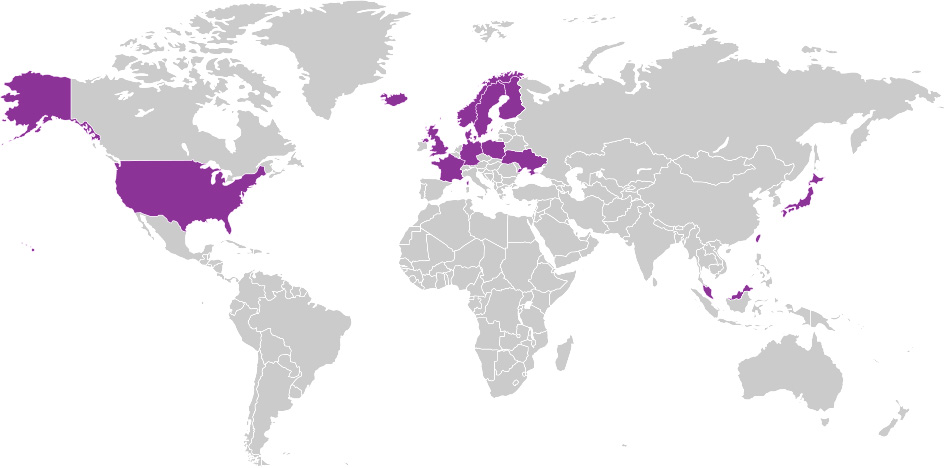

Transition Technologies Group in figures:

25years of experience

800+specialists at Transition Technologies PSC

2000+specialists in Transition Technologies group

15offices in Poland

7offices: in the USA, France, Denmark, Germany, Great Britain, Taiwan, Malaysia

_Currently implemented grants

PIONEER

PIONEER aims the development of an open innovation platform and interoperable digital pipeline for addressing a design-by-simulation optimisation framework.

HORIZON-CL4-2022-RESILENCE-01 – Grant Agreement ID: 101091449

Budget: 5.223.386,25 €

Runs from 01.01.2023 to 31.12.2025

TT PSC S.A. – consortium partner

Nowadays, European manufacturing enterprises are facing a number of challenges in a turbulent globalized market facing unprecedented and abrupt changes in market demands, an ever-increasing number of product variants and smaller lot sizes, intensifying the worldwide competition and causing a continuous pressure on production costs, product quality and production efficiency. Therefore, novel product development strategies for ensuring and optimising the manufacturing of new products or variants in low-volume production systems must be implemented.

For that, PIONEER implements inline feedforward control strategies for enhancing the efficiency of the industrial systems in high-mix/low-volume production schemes, based on the connection between materials modelling and materials characterisation, simulation-based digital twins and data-driven models, updated through distributed production data from embedded IoT edge devices and product quality. PIONEER is built over five pillars for development a common methodology deployed in two demonstrators by involving multidisciplinary optimisation for ensuring certified path planning strategies for the manufacturing of topology optimised structural elements through Wire-Arc Additive Manufacturing (WAAM) in construction –i.e., low-volume production schemes–, as well as for ensuring an efficient design and manufacturing strategy for the manufacturing of Carbon Fibre Sheet Moulding Compound (CF-SMC) components in automotive –i.e., high-mix production schemes.

PIONEER is built on the knowledge and results gained in:

- previous H2020 EU projects;

- associations –i.e. EMMC ASBL, IOF, VMAP Standard Community, IDTA—;

- commercial products from project partners.

PIONEER will bring together 14 key industrial and academic stakeholders from 11 countries.

Project website

INSPIRE

INSPIRE -modularization of the welding INSPector profIle to REspond to the needs emerging from hydrogen programmes towards a greener Europe

KA220-VET – Cooperation partnerships in vocational education and training (KA220-VET)

Grant Agreement ID: 2024-1-FI01-KA220-VET-000249269

Budget:€ 250 000,00

Runs from01.11.2024 – 31.10.2026

TT PSC S.A. – consortium partner

INSPIRE aims to modernize the European Welding Inspector (EWI) qualification, meeting the demand for skilled personnel in H2 pipeline inspection, aligning VET with labour market needs through digital transformation, to:

- Modularize the EWI qualification framework

- Implement new modularization and pilot training materials,

- Develop digital and innovative training materials using AR/VR technologies.

INSPIRE will implement a modularized European Welding Inspector qualification framework, emphasizing flexibility and using AR/VR tools for interactive training. The project focuses on emerging technology, addressing H2 pipeline inspection challenges to prepare workers for the energy sector. Innovative training materials will be developed to modernize VET. The project includes 5 national multiplier events, 3 national pilot events, and a European final conference to disseminate/validate outcomes.

INSPIRE anticipates significant outcomes, including a modularized EWI qualification framework enabling accessible training for tailored skills. Updated materials for H2 pipeline inspection will enhance knowledge, aligning with climate change goals. The project contributes to a skilled labour pool supporting environmental objectives. Additionally, digital tools will enhance training, ensuring VET remains open to industry trends, and fostering digital capacity for welding inspection professionals

_Completed grants

PENELOPE

Closed-loop digital pipeline for a flexible and modular manufacturing of large components

H2020-EU.2.1.5.1 – Grant Agreement ID: 958303

Budget: 20.125.750,35 €

Runs from 01.10.2020 to 31.03.2025

TT PSC S.A. – consortium partner

New planning for large-part manufacturing.

Machining large parts requires more than just a lot of space. There is also a variety of sub-assemblies and the capability to customise (build to customer demands). This high degree of personalisation hinges on the design and the posterior verification after manufacturing. With this in mind, the EU-funded PENELOPE project will develop a methodology linking product-centric data management and production planning and scheduling in a closed-loop digital pipeline. The aim is to ensure accurate and precise manufacturability from the initial product design. The project is built to develop the methodology and vision in the following sectors: oil and gas, shipbuilding, aeronautics, and bus and coach. It will also provide the training enabling the workforce transition towards Industry 4.0.

FLUENTLY

Fluently leverages the latest advancements in AI-driven decision-making process to achieve true social collaboration between humans and machines while matching extremely dynamic manufacturing contexts.

The project results will be: Fluently Smart Interface unit and the Robo-Gym.

HORIZON-CL4-2021-TWIN-TRANSITION – Grant Agreement ID: 101058680

Budget: 11.200.141,55 €

Runs from 01.06.2022 to 31.05.2025

TT PSC S.A. – consortium partner

The project is focused on performing industrial research leading to the creation of new technologies allowing utilization of sensor-equipped mobile devices for building a 3D mesh of the environment and interpretation of object geometry in near-real-time for the purpose of rapid development of worlds for Augmented (AR), Mixed (MR) and Virtual Reality (VR) games based on real-world environments. Creation of new heuristic methods ensuring a high level of accuracy of object recognition in a 3D space, including utilizing multiple area scanning devices simultaneously, is vital in order to achieve the aforementioned goals. Usage of Artificial Neuron Networks for object recognition based on a 3D mesh will be validated through the course of the research. Existing 2D image recognition algorithms will not be of direct use in these activities, but will be utilized as the starting point. Optimization of performance of the technology will be a significant issue – thus heuristics instead of precise algorithms, which allows for cooperation between multiple users immersed in the same virtual environment. The influence of given elements (algorithms, number of scanning devices, connection throughput) will be evaluated for their influence on accuracy and effectiveness of object recognition, providing insight as to optimal methods combining satisfactory recognition with dynamic collaboration between multiple users in near-realtime.

Synchronization of heuristic algorithms with the ability to dynamically and simultaneously model the environment by multiple devices, including a 3D developmnet environment in AR/MR/VR as well as desktops, will be one of key topics.

IMPROVE

Innovative Modeling Approaches for Production Systems to raise validatable efficiency

H2020-EU.2.1.1. Grant Agreement ID 678867

Budget: 4.148.554,00 €

Runs from 01.09.2015 to 31.08.2018

TT S.A., TT PSC S.A. – consortium partners

The project is focused on performing industrial research leading to the creation of new technologies allowing utilization of sensor-equipped mobile devices for building a 3D mesh of the environment and interpretation of object geometry in near-real-time for the purpose of rapid development of worlds for Augmented (AR), Mixed (MR) and Virtual Reality (VR) games based on real-world environments. Creation of new heuristic methods ensuring a high level of accuracy of object recognition in a 3D space, including utilizing multiple area scanning devices simultaneously, is vital in order to achieve the aforementioned goals. Usage of Artificial Neuron Networks for object recognition based on a 3D mesh will be validated through the course of the research. Existing 2D image recognition algorithms will not be of direct use in these activities, but will be utilized as the starting point. Optimization of performance of the technology will be a significant issue – thus heuristics instead of precise algorithms, which allows for cooperation between multiple users immersed in the same virtual environment. The influence of given elements (algorithms, number of scanning devices, connection throughput) will be evaluated for their influence on accuracy and effectiveness of object recognition, providing insight as to optimal methods combining satisfactory recognition with dynamic collaboration between multiple users in near-realtime.

Synchronization of heuristic algorithms with the ability to dynamically and simultaneously model the environment by multiple devices, including a 3D developmnet environment in AR/MR/VR as well as desktops, will be one of key topics.

Real World Engine

Development of interactive methods for spatial mapping and modelling for rapid design of vast digital worlds in mixed reality

POIR GameINN – Grant Agreement ID: POIR.01.02.00-00-0177/17-00

Budget: 2.412.446,40 PLN

Runs from 02.01.2018 to 30.03.2021

TT PSC S.A. – project leader (single-entity project)

The project is focused on performing industrial research leading to the creation of new technologies allowing utilization of sensor-equipped mobile devices for building a 3D mesh of the environment and interpretation of object geometry in near-real-time for the purpose of rapid development of worlds for Augmented (AR), Mixed (MR) and Virtual Reality (VR) games based on real-world environments. Creation of new heuristic methods ensuring a high level of accuracy of object recognition in a 3D space, including utilizing multiple area scanning devices simultaneously, is vital in order to achieve the aforementioned goals. Usage of Artificial Neuron Networks for object recognition based on a 3D mesh will be validated through the course of the research. Existing 2D image recognition algorithms will not be of direct use in these activities, but will be utilized as the starting point. Optimization of performance of the technology will be a significant issue – thus heuristics instead of precise algorithms, which allows for cooperation between multiple users immersed in the same virtual environment. The influence of given elements (algorithms, number of scanning devices, connection throughput) will be evaluated for their influence on accuracy and effectiveness of object recognition, providing insight as to optimal methods combining satisfactory recognition with dynamic collaboration between multiple users in near-realtime.

Synchronization of heuristic algorithms with the ability to dynamically and simultaneously model the environment by multiple devices, including a 3D developmnet environment in AR/MR/VR as well as desktops, will be one of key topics.

INEDIT

Open Innovation Ecosystems for Do It Together process

H2020-EU.2.1.5.1 – grant agreement no 869952

Budget: 6.887.475 €

Implemented from 01.10.2019 to 31.03.2023

TT PSC S.A. – consortium partner

INEDIT creates an open innovation European DIT ecosystem for sustainable furniture co-creation. It channels the

creativity of consumers, shapes it through designers’ professional skills, and makes it viable by leveraging on the

expertise of production specialists in order to deliver sustainable, smart and personalized new products in a shorter

time to market. INEDIT intends to demonstrate the capacity to turn the well-known ‘Do It Yourself’ (DIY) approach

applied by individuals within FabLabs into a professional approach named ‘Do It Together’ (DIT). The DIT approach will

be applied by customers and professional producers, especially SMEs, for conveying higher customer satisfaction through

customer-driven production. DIT is a novel approach capitalizing on the knowledge, creativity and ideas of design and

engineering conceptualized by interdisciplinary stakeholders and sometimes even new actors. It is powered by existing

European innovation ecosystems shaping new products across EU countries. INEDIT demonstrates the approach through four

cross use cases with high societal impact: sustainable wood panels manufacturing and 3D-printing of wood, 3D printing of

recycled plastic and Smartification. Sustainability and consideration of individual preferences, especially of women and

men, will be our guiding thread. INEDIT address societal challenges such as contribution to reduce the amount of

produced CO2 in focusing on European-wide production, creation and maintenance of EU-wide job opportunities. This will

lead to new business opportunities supported by business model innovation. Moreover, these innovative networked local

manufacturing competences and production facilities across the EU will solve ethical concerns within the manufacturing

network. INEDIT intends to demonstrate, through its twin – digital and physical – platform, the potential innovation

around social manufacturing within the circular economy in designing global while producing local.

Connected Worker

A system increasing the efficiency of remote communication and collaboration, thanks to hardware-agnostic AR technology based on a real-time spatial mapping and tracking powered by edge/cloud computing and 3G/4G/5G networks.

POIR Szybka Ścieżka Koronawirusy – Grant Agreement ID: POIR.01.01.-00-2613/20-00

Budget: 5 305 218,59 PLN

Runs from 01.09.2021 to 30.11.2023

TT PSC S.A. – project leader (single-entity project)

EU shipbuilding leading edge relies in the complexity, quality, customization, delivery time and lifecycle services (e.g. in situ maintenance, repair and retrofitting) of the vessels manufactured. However, in the last decade, EU small and medium-sized shipyards (SME) have experienced a competitive drawback in their market segments due to an increase of competition from other global regions that benefits from lower labour costs or higher automation degree. Moreover, SME shipyards must also overcome a major impediment related with capital investment that can overwhelm the part cost for shipbuilding. As a result, current automation solutions based on large monolithic equipment, are not still valid for increasing productivity in SME shipyards.

Therefore, shipbuilding, and especially SME shipyards, needs novel cost-effective, reconfigurable, modular and flexible worker-centric methodologies capable of improving worker’s performance and ensuring quality and precision in the execution of the labour-intensive tasks.

Mari4_YARD aims the implementation of a portfolio of worker-centric solutions, by relying on novel collaborative robotics and ubiquitous portable solutions, enabling modular, reconfigurable and usable solutions targeting the execution of labour-intensive tasks by preserving industry-specific workers’ knowledge and skills.

Moreover, replicability and early-adoption of the portfolio of technologies by other SME-shipyards is ensured through several actions on training, technology assessment, benchmarking… by establishing a pan-European network of Didactic Factories, offering general-purpose testbeds and showrooms, as well as providing upskilling and re-skilling of shipyards workforce.

To further maximise the impact, Mari4_YARD plans to use synergies with complementary European and national initiatives, especially those related to MG-3-7-2020. A strategy for collaboration with Mari4_CHAIN and Mari4_PRO proposals, if funded as well, has already been set up.

Mari4_YARD

User-centric solutions for a flexible and modular manufacturing in small and medium-sized shipyards

H2020-EU.3.4 – Grant Agreement ID: 101006798

Budget: 5.913.440,00 €

Runs from 01.12.2020 to 30.11.2024

TT PSC S.A. – consortium partner (leader of the AR work package)

EU shipbuilding leading edge relies in the complexity, quality, customization, delivery time and lifecycle services (e.g. in situ maintenance, repair and retrofitting) of the vessels manufactured. However, in the last decade, EU small and medium-sized shipyards (SME) have experienced a competitive drawback in their market segments due to an increase of competition from other global regions that benefits from lower labour costs or higher automation degree. Moreover, SME shipyards must also overcome a major impediment related with capital investment that can overwhelm the part cost for shipbuilding. As a result, current automation solutions based on large monolithic equipment, are not still valid for increasing productivity in SME shipyards.

Therefore, shipbuilding, and especially SME shipyards, needs novel cost-effective, reconfigurable, modular and flexible worker-centric methodologies capable of improving worker’s performance and ensuring quality and precision in the execution of the labour-intensive tasks.

Mari4_YARD aims the implementation of a portfolio of worker-centric solutions, by relying on novel collaborative robotics and ubiquitous portable solutions, enabling modular, reconfigurable and usable solutions targeting the execution of labour-intensive tasks by preserving industry-specific workers’ knowledge and skills.

Moreover, replicability and early-adoption of the portfolio of technologies by other SME-shipyards is ensured through several actions on training, technology assessment, benchmarking… by establishing a pan-European network of Didactic Factories, offering general-purpose testbeds and showrooms, as well as providing upskilling and re-skilling of shipyards workforce.

To further maximise the impact, Mari4_YARD plans to use synergies with complementary European and national initiatives, especially those related to MG-3-7-2020. A strategy for collaboration with Mari4_CHAIN and Mari4_PRO proposals, if funded as well, has already been set up.