Digital Orchestration for PTC

Maximize the Value of Your Investments in Digital Transformation

Who we are

We are experts in digital transformation, and our knowledge and experience let us spread the idea of constant technological development as evidenced by 1200 completed projects across the globe.

TT PSC gets partners to the next level through comprehensive action and professional advice. We understand technologies and use their potential to deliver business value and accelerate growth.

Why Transition Technologies PSC?

Global company

- Operating since 1991

- 23 offices across the globe

- 2000+ employees in the capital group

- 100% Private Polish Capital

Passionate people

- 800+ experienced IT specialists working for TT PSC

- 10+ Languages

Experience

- 6 areas of expertise

- 7 verticals

- 30+ countries

- 1200+ projects completed

Culture of partnership

We build and value long term relationships:

- 8 years of partnership with Rockwell Automation

- 22 years of cooperation with PTC

- 24 years of cooperation with Emerson

Today, we work with companies that are accelerating and broadening their investments in digital technologies for the valuable capabilities they deliver. Our customers are understanding that to achieve the greatest benefit from their digital transformation programs, their investments in infrastructure, technologies and solutions must perform well together. And, just like great symphony orchestras, the digital business orchestra requires a skilled conductor. The digital business orchestra needs a digital orchestrator.

Our Business DNA: Digital Orchestration for Digital Transformation

| Product design | Supply Chain Management | Manufacturing | Service & Sustainment | Marketing, Sales, and Support | |

|---|---|---|---|---|---|

| GOAL | Implement Closed-LooplProduct Lifecycle Designand Management | Enable Digital Threads & Continuity across all Supply Chain Nodes | Connect and OptimizeProduction Operations through IT / OT Integrations | Improve Relataly through Concition-Based, Predictive. Remote Montoring | Redefine the Customer Experience, from Purchase to Field Service |

| VALUE |

|

|

|

|

|

Our Solutions

| Product design | Supply Chain Management | Manufacturing | Service & Sustainment | Marketing, Sales, and Support | |

|---|---|---|---|---|---|

| System of Records | |||||

| Digital Work Instruction | |||||

| R-F-L-P Harmonization | |||||

| OFE | |||||

| Augmented Reality for Adoption | |||||

| Variant Management | |||||

| Cloud Readiness IaaS / PaaS / FaaS | |||||

| Integrated Quality Management | |||||

| Remote assistance / Monitoring | |||||

| APQP / ASPICE | |||||

| Light MESS | |||||

| Visualization from Variant Management | |||||

| Software Updates of SmaSP and FA |

Learn more about our approach and solutions

We are advising You on Transforming Your Business

Don’t hesitate to contact us!

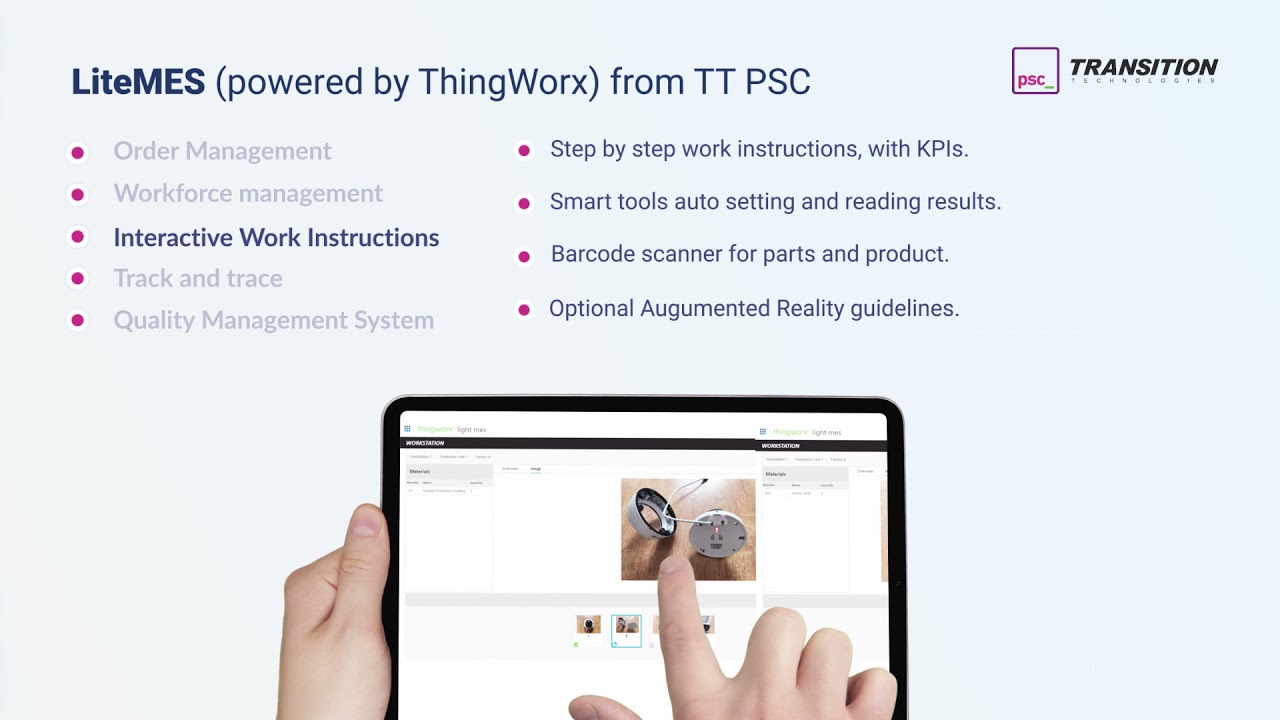

Introducing LiteMES powered by ThingWorx by TT PSC

A lightweight manufacturing execution system that delivers powerful capabilities for your factory's operations.

- Five important production management capabilities, in a lightweight application package.

- Cost efficient, rapid time-to-value capabilities – progressively integrated or stand alone.

- Easy to tailor. Focused, lightweight apps to fit your production operations, deliver the data you need.

- Connect quickly to factory data sources and enterprise solutions for immediate utility and value. The benefits you seek from MES, at a lower TCO.

Our Partners

Here is what customers say