Sustainability across the Engineering Digital Thread

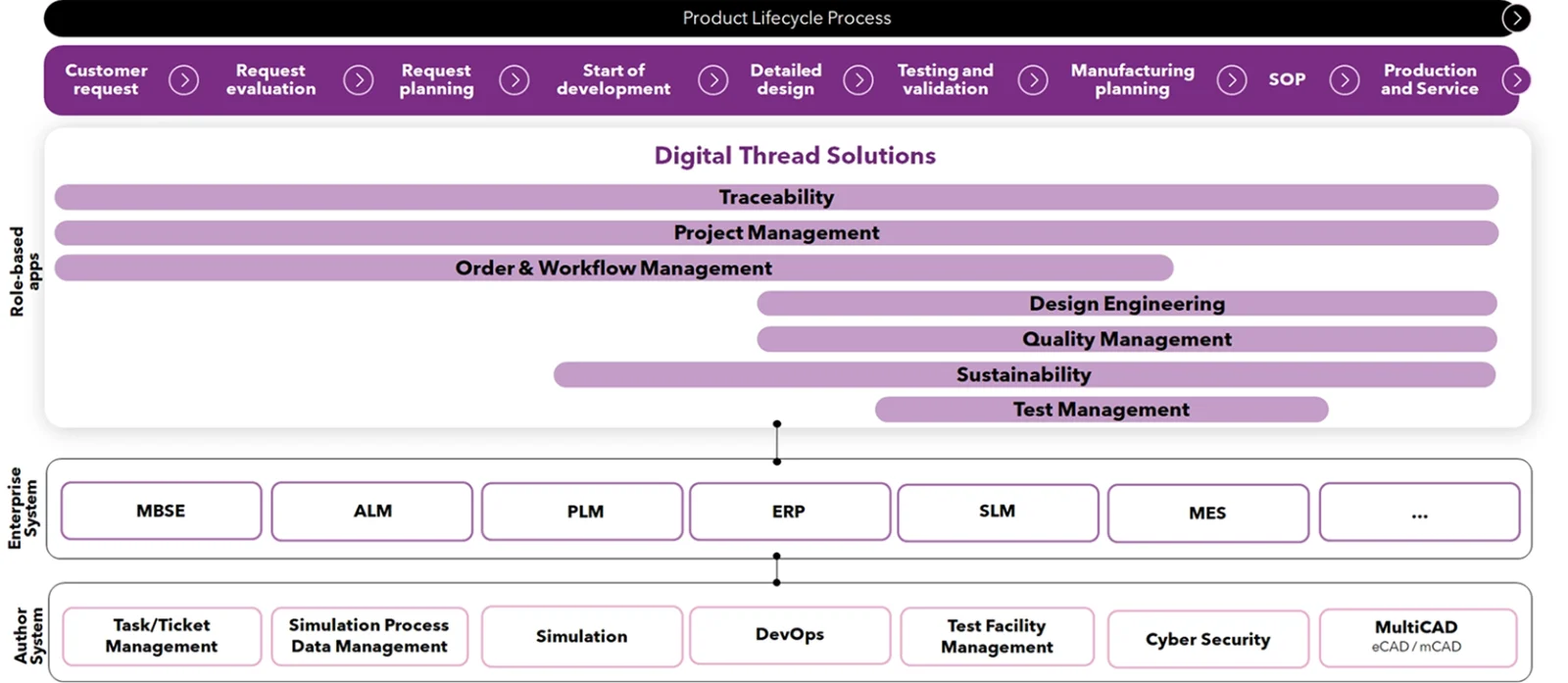

At Transition Technologies PSC, we are passionate about helping companies navigate their digital transformation journeys. Our focus extends beyond efficiency and productivity – we empower organizations to innovate responsibly, embedding sustainability into the very foundation of product engineering. By leveraging product lifecycle management (PLM) systems, digital twins, and integrated design tools, we support companies in […]