Energy data management system for manufacturing

Gain full visibility of your energy use in a single system. From the shop floor to the boardroom — and turn data into measurable savings.

Why energy management is hard to ignore today?

If you run a factory, you know how fast energy costs eat into your margins. Prices change, regulations tighten, and sustainability targets keep growing.

Without proper energy management, it’s hard to tell where energy is really going — which lines or machines waste the most, and what can actually be improved.

A solid energy data management system gives you real numbers in real time, so you can act early — before small inefficiencies turn into real costs.

Challenges faced by plant decision-makers

From hidden energy losses to unreliable data, these challenges prevent manufacturers from achieving true efficiency.

Energy Advisor - our tailor-made solution

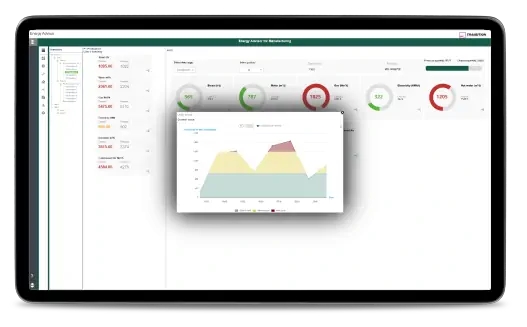

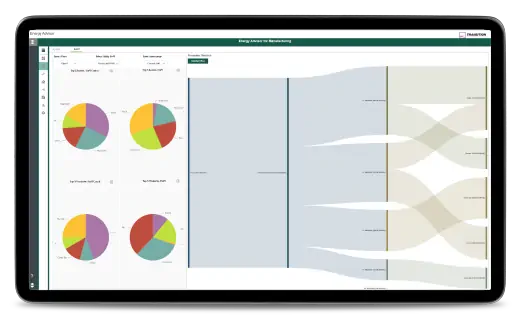

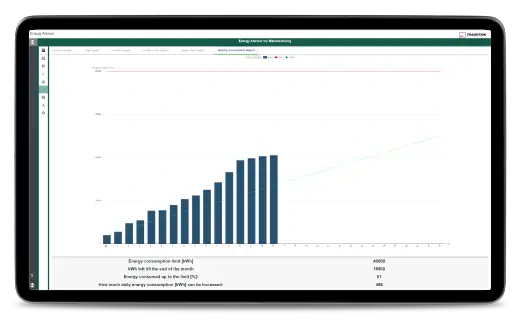

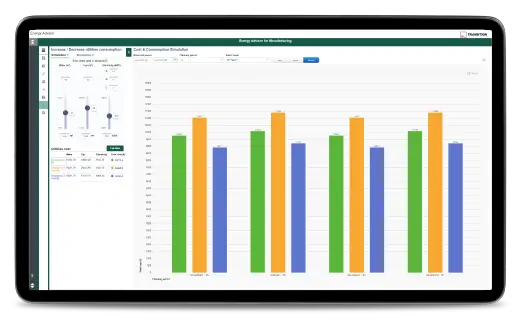

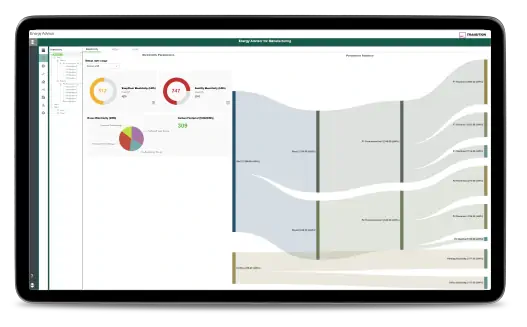

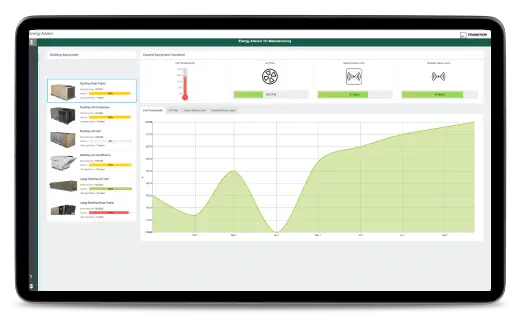

Energy Advisor helps manufacturing enterprises make sense of their energy data.It collects information from machines, production lines, and utilities, showing where and how energy is really used.

With it, you can see which areas generate the biggest losses, where investments will pay off fastest, and how to keep costs under control at any time.

It gives you facts you can rely on - useful not only for engineers on the shop floor, but for managers who make the financial decisions.

Energy management designed for your needs

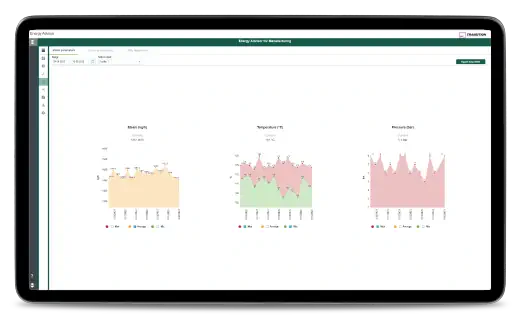

Our Energy Management Software provides a comprehensive suite of tools to manage energy consumption and improve efficiency across electricity, gas, water, and production processes. It also supports sustainability energy monitoring, helping you track progress toward your environmental goals.

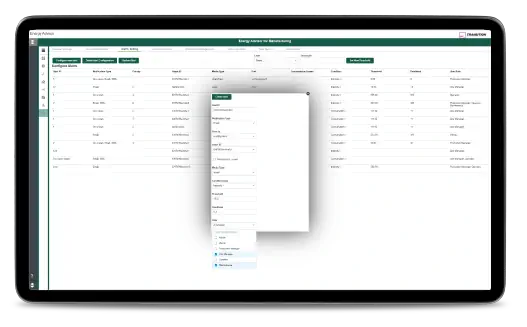

Thanks to our modular platform, you can integrate electricity, gas and water meters, production equipment, and even power-quality sensors – all within one unified system. It’s designed to work with minimal programming effort, ensuring a quick and seamless start.

The advantage of Energy Advisor over a standard EMS

Measurable results you can expect from energy management

Spot inefficiencies early and prevent unnecessary energy losses across operations.

Lower utility spending and optimise resource use without disrupting production.

Lower carbon emissions with data insights Energy data is scattered across many tools, making decisions slow and uncertain. Use verified data to track, control, and reduce your organisation’s carbon footprint.

Use verified data to track, control, and reduce your organisation’s carbon footprint.

Base every operational and investment choice on reliable, real-time energy data. Detect hidden losses caused by harmonics or unstable loads before they impact costs.

Detect hidden losses caused by harmonics or unstable loads before they impact costs.

Case Study

See how a global food manufacturer cut energy costs and improved sustainability with Energy Advisor by TT PSC.

- Automated data and real-time insights

- Measurable cost and CO₂ reductions

- Scalable solution for multi-site operations

Download the full case study to see the results.

Download PDFRecognised for excellence

Choose smart and simple energy management.

Watch the demo to explore how Energy Advisor visualises consumption, pinpoints inefficiencies, and supports smarter, data-driven decisions.

Why choose TT PSC

Feedback from our customers

Let’s talk about your energy goals

In 30 minutes, we’ll show you where your factory can save power, reduce costs, and improve overall performance.

Key system features

ISO 50001 certification support

Our Energy Management System is custom-built for your organisation — flexible, scalable, and aligned with your operational needs.

While it is not pre-certified, TT PSC collaborates with accredited certification bodies to help you achieve full ISO 50001 compliance after implementation.

Our experts and partners support you at every stage:

- Define Energy Performance Indicators (EnPIs)

- Map and document energy flows

- Ensure regulatory compliance

- Map and document energy flows

- Map and document energy flows

This approach gives you the best of both worlds — a tailored, data-driven system built around your operations, and the confidence to meet ISO 50001 requirements with full traceability and expert support.

Our process

A structured, step-by-step path toward comprehensive energy management — helping you lower costs, enhance efficiency, and achieve long-term sustainability.

This stage sets the foundation for digital transformation and informed decisions based on valuable insights.