Become a top example of a complete transition to Industry 4.0

Vol.3 / 3: Deep dive into Smart Factory in AWS – scale and roll out the solution for more than one factory

There are many digital technologies that enable organizations to increase efficiency in various areas. In this maze of new solutions, it is often difficult for decision-makers to find the right one. For manufacturing companies, the obvious choice seems to be Industrial IoT and striving for the idea of Industry 4.0 – Smart Factory (in AWS). The reason is simple; they contribute to answering manufacturers’ main pain points, such as:

• too many and too long downtimes,

• ineffective maintenance process,

• lack of expansion to the new markets and business models,

• unsatisfactory level of customer service.

In our second article, we focused on the MVP implementation of one business case. We are at the stage where we have confirmed that our organization is ready for the digital revolution. And we’re not just talking about machines and processes, but also about preparation of your employees for inevitable changes and taking full advantage of the AWS cloud capabilities. Now it is time to act on a bigger scale and rollout the solution in other factories, where cloud features are extremely helpful.

If you missed the opportunity to read articles 1 and 2 in this series, no worries. Here are the links:

Smart Factory in AWS no.1

Smart Factory in AWS no.2

Digital transformation and moving towards the idea of Industry 4.0 (I4.0) & Smart Factory (in AWS) are not easy. There are many obstacles waiting for the implementers. The most common are pilot purgatory and scale purgatory.

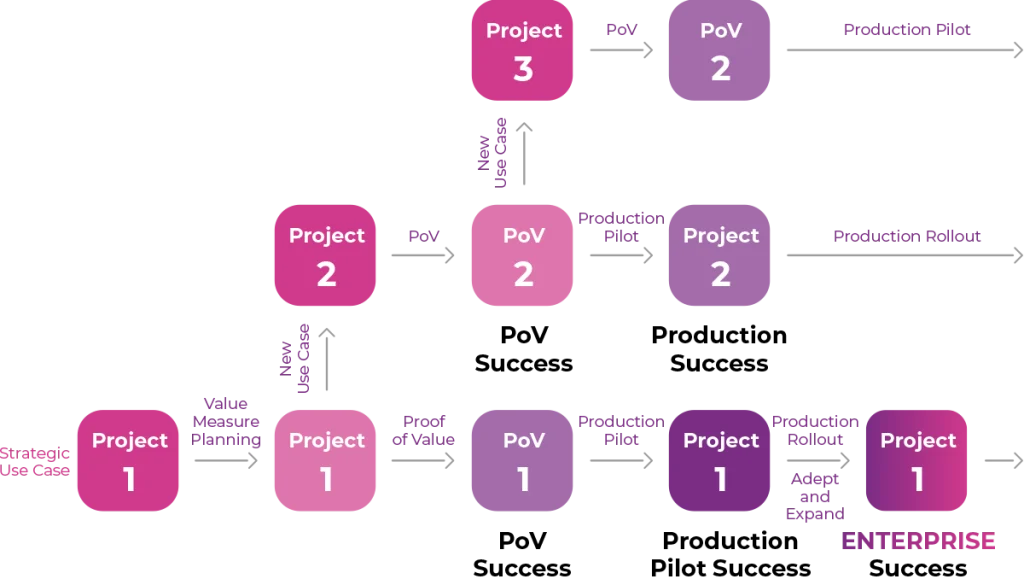

We mentioned pilot purgatory (how not to stuck in it) in article number 2 in the cycle. It occurs when, after the first business case is implemented, digital projects are put on hold and do not make it to production. This is often the result of manufacturers focusing only on business cases that solve challenges technologically, selectively and without examining the financial impact, and/or striving to „put two saddles on one horse” (implementing several projects simultaneously).

The scale purgatory, which we will focus on preventing in this article, is a more recent harmful phenomenon. In this case, on the path to digital transformation, manufacturers are struggling to duplicate initial successes (implementation of the first MVP) across multiple locations in an effective manner. This lack of scalability can slow down the pace of progress towards Industry 4.0 and even result in a loss of executive support.

Anticipate needs of further adoption and scaling

For global companies with numerous factories around the world, two dilemmas usually arise: whether to focus on local processes and IT systems when improving, which will only result in regional development and maintenance costs. Or whether to move towards standardization and scale, i.e., universal solutions that meet global needs but do not always solve all the problems of local factories. Differences in business data from different countries or different systems located in factories are also a challenge.

Business processes differ depending on the location of the factory, and often depend on regulatory requirements in a given country, which in turn has a negative impact on the attempt to adjust them to global conditions.

Different locations also mean different requirements. The use of locally popular IT systems in different countries causes compatibility issues for IT resources, which in turn requires significant adaptation to the rules of the game and is a barrier for organizations looking for a single universal/standard and global management and reporting tool. This creates challenges related to integrating multiple IT systems into a single global application.

Therefore, it is necessary to design flexibility and adaptability to changes into the new IT system. Again, using AWS Cloud services can instantly solve most of the issues.

All these challenges mentioned above should be addressed before they generate high costs or delay

implementation of the transformation.

Large-Scale digital transformation challenges

How not to end up in pilot or scale purgatory?

A common phenomenon is a situation where the digital transformation towards Industry 4.0 ends after the first pilot implementation or the implementation of the first MVP. Organizations do not modify business processes or optimize IIoT solutions for more extensive use. Without a holistic approach to the topic and an estimation of how to translate solutions from micro to macro scale, decision makers and key stakeholders agree to 100% cut off the future benefits of implementing Smart Factory idea across the organization.

To understand the key factors behind capturing IIoT-based value on a large scale, we relied on our extensive experience in successfully scaling IIoT. We can certainly offer our experience in digital transplant strategies. We are happy to share some of them.

As we mentioned in the second article in the series (Smart Factory in AWS no. 2), it is extremely important

to prepare a complete list of business cases and prioritize them. Both a top-down and a bottom-up approach should be used to generate a comprehensive list. Taking into account the potential financial impact and how easy it is to implement the business cases, we select the most important and feasible. We analyze the business cases in terms of their replicability across the organization, not just in one factory. Some cases will be unique and one-off, some will be applicable to a second plant, and potentially a lot of them may be replicated several times.

Adaptive scalability to multiple production projects

Lesson learned from the first MVP implementation

Embarking on a full global transformation is a challenge and only a few succeed. Based on many years of

experience, we have developed a specific approach to industrialized implementation, preceded by an MVP implementation phase. This approach includes standardization, predictability and repeatability of the entire transformation process. It enables all locations to use the newly implemented solutions, thus accelerating market entry and global implementation.

As written in the second article in this series, the first MVP is rarely perfect and meets our needs 100%. Nevertheless, it is an excellent opportunity to gather unique experiences. It is also enough to check if your organization is ready for the digital journey towards Industry 4.0. We should revise and adapt the digital transformation roadmap based on what we have learned and keep in mind the need for the solution to be scalable to the rest of the factories globally.

The implementation of the first MVP should occur before the actual implementation and rollout of the system in all regions. The preparatory work and lessons learned from the MVP implementation are essential to solving the dilemma of locality versus standardization. The MVP allows you to assess the current state by collecting, filtering and evaluating input data. Thanks to this, you can identify functionality and business requirements gaps, prioritize other business cases, and estimate the workload and costs needed for large-scale implementation.

The result is an updated roadmap, as well as a role-based training schedule, which in turn enables you to start a large-scale industrial implementation.

Planning a rollout for all factories

The initial step of a large-scale deployment is to implement an initial solution with limited but proven profitability (MVP), followed by a pilot implementation in a selected region, focusing on achieving the assumed business goals.

Only then can you move on to structuring and automating the whole organization. The smooth transformation of a global deployment depends heavily on reducing variations between locations. Prioritize these locations with the highest standardization and minimal variability. This approach will allow you to later develop standards for locations with higher variability.

It’s also important to use tools that allow you to standardize, unify and – above all – automate deployments, so you can focus on delivering business results rather than IT operations. This is a core idea of DevOps culture – also supported by many AWS Cloud services.

The success of IIoT is also based on organizational changes. This means a different role distribution and different requirements for the workflow, especially when it comes to combining IT and OT, which includes:

- a single and shared management model.

- consistency of processes,

- a holistic approach to data and security management.

Preferably, you should also had a plan on how to further expand the organization’s understanding of how to develop, implement and handle IIoT use cases, including having experts trained and hiring new ones.

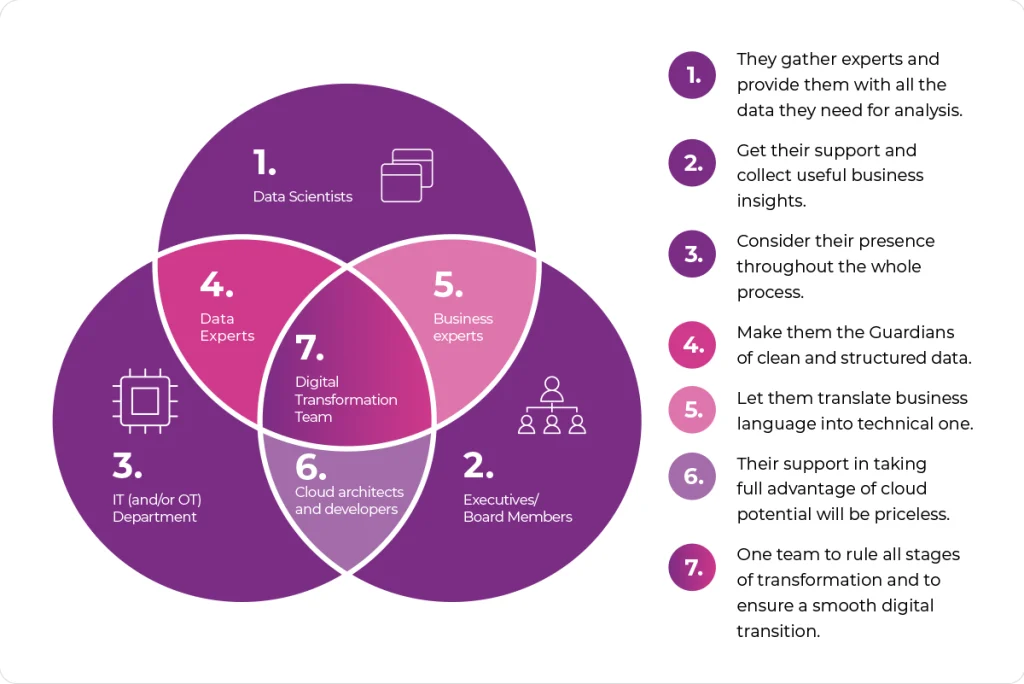

People you may need on your Industry 4.0 journey

One of the most important things in industrial implementation is for all participants to be in constant

communication with the Digital Transformation Team. This team is responsible for training and proper

communication within the organization. This strategy is designed to keep the message and direction of the transformation consistent for all regions.

Let’s get to the point – start implementing the solution in

more than one factory

Implementing the solution in the remaining factories begins with an analysis and examination of the readiness for digital transformation at all locations, as well as cloud maturity. Check regional status and level of variability for key factors affecting the implementation, such as appropriate data preparation or compliance with local business processes and IT systems.

The (AWS) cloud definitely helps with IIoT transformation, as it provides companies with valuable benefits such as access to artificial intelligence (AI) and machine learning – not really achievable on a professional level when staying on-premise.

Cloud transformation scaling includes:

- Analysis – assessing the current cloud maturity level and identifying gaps.

- Cloud strategy – achieving the digital objectives set for the company requires a lot of engagement and consistency in actions. A well-prepared plan is a guarantee that your migration to the cloud will proceed in a goal-oriented manner.

- Cloud migration – fully adopting cloud technology and carrying out full-scale digital

- transformation.

- Scaling – driving business change on a global scale.

Each location (factory) that successfully passes the readiness test proceeds with the onboarding and data

migration process. Do not forget to train employees on how to utilize the new systems.

All the templates support a smooth implementation, such as data collection and migration. With this tool, they can be easily collected and imported into one system. This prevents us from differences in data and variations in all locations. It is also a quick validation – the first checkpoint – before any data transfer. We transfer data in sets and stages, which facilitates data testing and reduces the margin of error.

User acceptance testing begins as soon as all data is in the test system. Users should be trained on the functioning of the new systems to test them before deployment to a working production environment.

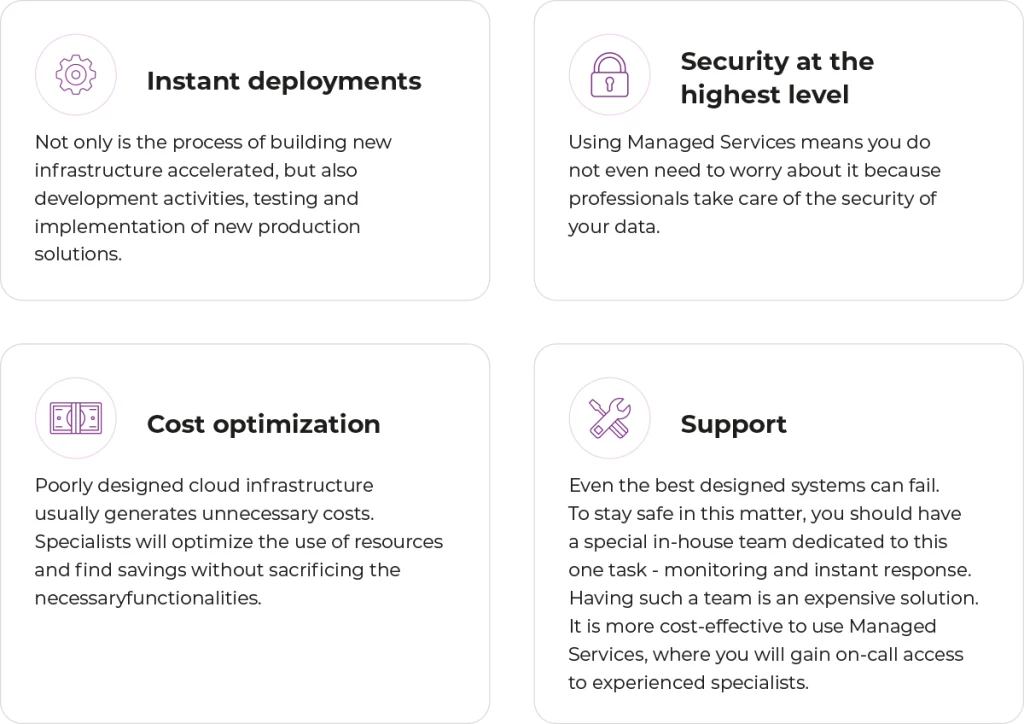

A Managed Services phase follows post-deployment to handle the rise in post-launch queries. Managed

Services runs from the beginning of the implementation and provides professional technical assistance. It

helps users to become amiliar with new systems and facilitates their transition to smoothly navigate the

new reality.

The essence of Adaptation and Managed Services

Digital Transformation Team is responsible for a smooth digital transition, which also means adapting the whole organization to the new system. As we mentioned, this team develops training plans for employees to be more aware and use the new solutions/programs/systems smoothly over time. Proper communication about digital transformation and its “why? when? how?” within the organization is equally important.

With the increasing maturity of the enterprise on the journey towards full digital transformation, the use of cloud services is also growing. The cloud means faster implementation of new business cases, greater flexibility of projects, it is also the basis for technologies such as the Internet of Things or Augmented Reality.

Migration to and proper management of the cloud are indispensable parts of digital transformation and the very concept of Industry 4.0.

Managed Services provide peace of mind, mainly due to the optimization of cloud costs, as well as the skillful use of its full potential through the specialists’ know-how.

Main benefits of Managed Services:

A final word before you proceed to “Smartify” your Factory

According to IDC (International Data Corporation), global spending on digital transformation by 2023 will reach $6.8 trillion. More and more organizations are taking the plunge into digital transformation in line with the idea of Industry 4.0. They are facing organizational and technological challenges. Therefore, it is essential to follow a solution implementation approach that allows for standardization and flexibility across different factory locations. An industrialized approach to implementation kicks off by defining clear requirements, goals and KPIs that holistically take into account both regional and global viewpoints.

Keeping up with the fourth revolution cannot change the way people work. An agile approach and a set of standardized processes are an indispensable part of any digital transformation. They help employees communicate more effectively and drive digital transformation from a global perspective, while at the same time allowing for tailoring solutions to the needs of individual regions. Full involvement of all parties is the key to a successful digital transformation.

A holistic approach to IIoT, taking into account the needs of the organization and the business and technology, helps overcome the bottlenecks between implementing initial scalable business cases and finalizing the implementation across the company.