What is an Energy Management System for Manufacturing? A Complete Guide

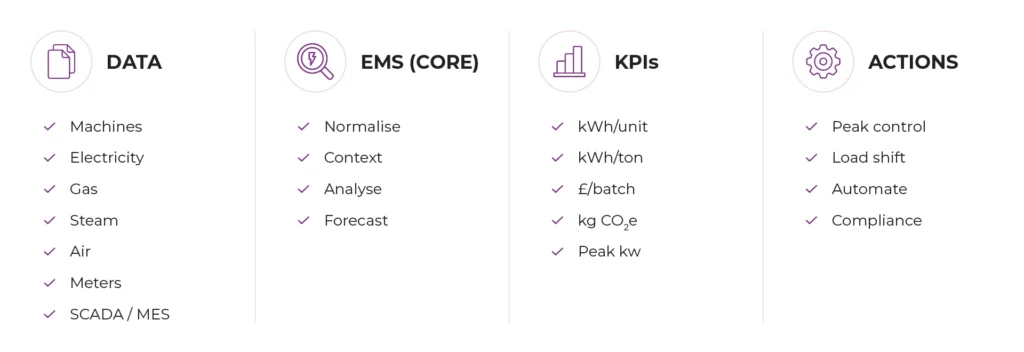

An Energy Management System (EMS) for manufacturing is a combination of software, sensors/meters, and management processes that helps a plant measure, analyse, and control energy use across machines, lines, and utilities. Its purpose is to reduce energy cost, improve operational efficiency, and support compliance and sustainability targets.

In practice, an EMS continuously collects energy data (e.g., electricity, gas, steam, compressed air), converts it into production KPIs (such as kWh per unit, £ per batch, peak demand, and baseline vs actual), and enables workflows that turn insights into action (alerts, scheduling, maintenance, and optimisation).

Why energy volatility hits manufacturing KPIs

In manufacturing, energy spend can change quickly and shows up immediately in the KPIs plants manage every day-kWh per ton/unit, £ per ton, and peak kW that drives demand charges. This is why visibility matters: when energy is only visible at invoice level, plants cannot act on it shift-by-shift or line-by-line.

Peak kW events often influence the bill more than total kWh, because short spikes can trigger higher charges even when overall consumption stays flat.

It also affects utilities most factories rely on continuously (electricity, gas, steam, compressed air), so shifts in tariffs or load profiles translate into real differences in operating cost per batch and per shift. The figures below summarise the scale of recent price movement and the measurable impact that structured energy management can have on both energy consumption and operating costs. Coordinated energy management efforts are essential for improving energy efficiency and controlling costs, especially in volatile energy markets.

| Energy monitoring | Energy Management System (EMS) | |

|---|---|---|

| What it shows | Current and historical energy usage (kWh, m³, £) | Energy usage in context of production, assets, shifts and processes |

| Time horizon | Short-term, descriptive (what happened) | Short- and long-term, analytical and predictive (what happened, why, and what will happen) |

| Decisions supported | Basic awareness and reporting | Operational optimisation, cost control, peak demand management, compliance and continuous improvement |

Production KPIs and energy data that matter

Utility spend in manufacturing is not a fixed overhead – it is a set of measurable production variables that can be tracked to specific assets, lines, and shifts.

When electricity, gas, steam, or compressed air usage changes while output remains stable, the impact shows up in indicators such as kWh per ton, £ per ton of material produced, peak demand (kW), and baseline vs actual variance (%).

This is why energy management strategies start with visibility: you can’t reduce energy consumption if it is only visible at invoice level. Developing a clear energy management plan is essential to guide optimisation efforts, address challenges such as upfront costs, lack of expertise, and regulatory complexities, and ensure continuous improvement. An energy management program embeds energy management practices into daily plant KPIs – targets, actions, verification, and continuous improvement—so optimisation is repeatable across lines, shifts, and sites.

A modern energy management system connects utility metering with production context (SCADA/MES/ERP) so you can see energy per product, per batch, and per shift.

The same energy management system can forecast utility cost using historical patterns and current tariffs, and it can translate usage into carbon emissions (kg CO₂e per unit) to support energy regulations and audit-ready reporting across multiple sites.

This is why energy management strategies start with visibility: you can’t reduce energy consumption if it is only visible at invoice level. Practical examples of how manufacturers translate production-level energy data into measurable savings are discussed in Energy savings for manufacturing, which focuses on real operational drivers rather than isolated efficiency initiatives.

Hard metrics to track in manufacturing energy management

| Metric | Unit / format | What it tells you |

|---|---|---|

| Energy intensity | kWh/ton or kWh/unit | Energy used per unit of output (core efficiency KPI) |

| Unified utility cost per output | £/ton, £/batch, £/SKU | Total utilities cost allocated to production output |

| Peak demand | kW peaks + demand-charge exposure (£/kW) | Demand spikes that drive demand charges and bill volatility |

| Baseline vs actual variance | % deviation by line/product/shift | Whether energy use is within expected range for a given context |

| Compressed air performance | flow/usage + cost per hour or per line | Cost and losses tied to one of the most expensive utilities |

| Energy distribution losses | % (incomer vs sub-meter totals) | Losses/unmetered loads between supply and consumption points |

| Carbon intensity | kg CO₂e/ton or kg CO₂e/unit | Emissions per unit of output (Scope 1–2 visibility per product) |

| Forecast accuracy | % error (predicted vs actual) | How reliable cost/consumption forecasts are for planning |

| Power quality | voltage events, power factor, harmonics | Electrical quality issues affecting stability, downtime risk, and cost |

What is energy management in simple terms?

In simple terms, energy management means understanding where energy is used, reducing waste, and using energy only when and where it adds value to production.

What is an example of energy management?

A practical example is using an energy management system to reduce peak demand: monitoring real-time kW, the timing of energy produced and consumed on site, and shifting non-critical loads (HVAC, compressed air cycles, CIP timing) to off-peak demand periods without disrupting production.

Dashboards from the energy management system confirm the impact through lower peak kW, improved alignment between energy produced and energy used, and lower £/batch. These actions directly help cut energy costs for the facility.

Beyond peak demand reduction, manufacturers use energy management systems to optimise scheduling, eliminate idle loads and improve utility efficiency at line and process level. A set of practical, production-focused examples is outlined in 5 ways Manufacturers Can reduce energy Costs, which shows how these actions translate into measurable savings rather than one-off initiatives.

Who is an Energy Management System for?

- large & energy-intensive manufacturers

- multi-site operations

- plants with high peak demand

- companies under ESOS / SECR

Especially relevant where energy costs are a material part of unit economics rather than a fixed overhead.

Companies challenges and needs

- Energy costs and electricity costs are harder to predict, which increases operational costs and disrupts budgeting for energy intensive processes.

- Plants need to optimise energy consumption and optimise energy usage without risking power supply stability across industrial processes.

- Renewable energy variability increases operational risk, so operations must plan for changing energy demand, manage energy resources, and maintain grid stability.

- To cut utility bills and avoid peak demand penalties, plants need real time monitoring, real time data on energy consumed, and alerts for abnormal energy usage and energy waste.

- Effective energy management requires linking energy performance to emissions and regulation, including audit-ready reporting for energy regulations.

- Many organisations lack consistent energy data and data collection across sites and utilities, limiting a repeatable energy management program.

- Energy saving technologies can be hard to implement, due to upfront costs, lack of expertise, and resistance to change. Energy consultants can provide valuable support in designing and optimizing energy management systems for manufacturing plants.

Developing a clear energy management plan is essential to guide optimisation efforts, address challenges such as upfront costs, lack of expertise and regulatory complexity, and ensure continuous improvement. A structured, step-by-step approach to this journey is described in 5 steps to increase energy efficiency for Manufacturers, which breaks energy improvement into practical and repeatable stages.

Types of energy management systems

In manufacturing, energy system management solutions can be classified by delivery model (off-the-shelf vs custom-built), control logic (rule-based vs forecast-based), deployment (cloud/EIS), and industrial scope (IEMS).

A comprehensive energy management solution typically standardises monitoring and reporting across sites; in practice, plants choose between such platforms and custom solutions that mirror site-specific KPIs and allocation logic.

It is also important that an Energy Management System integrates with existing building management systems (BMS) for real-time monitoring and automation. Industrial energy management systems are designed specifically for plants and refineries, offering continuous monitoring and analytics to improve performance and reduce cost.

Delivery model: off-the-shelf vs custom-built

- Off-the-shelf: quicker start, standard dashboards/connectors, limited flexibility for plant-specific KPIs and allocation logic.

- Custom-built: tailored to operational processes, tighter SCADA/MES/ERP fit, production-aware KPIs (kWh/ton, £/batch), and more control over the roadmap (renewables, demand response, automation).

Control approach: rule-based vs forecast-based

- Rule-based: predictable logic for energy distribution across connected assets (e.g., peak-demand load shedding).

- Forecast-based: forecasting + optimisation for volatile tariffs, variable renewables, and multi-line constraints.

Platform type: cloud-based EMS and EIS

- Cloud-based EMS: remote access to energy data and tools across sites.

- Energy information system EIS: cloud layer that collects and analyses gas and electricity usage data.

Energy management system as a solution

Many vendors offer tools that monitor energy consumption, but they often stop at utilities data alone.

For manufacturing teams, a chart showing “high usage” at a workstation is rarely enough – because the real question is whether that usage is acceptable for the actual output. Only when metering data is directly compared with production reports (e.g., kWh per ton, cost per batch, peak demand per shift) can a plant judge performance and act to optimise energy usage and reduce energy consumption in a controlled way across key processes.

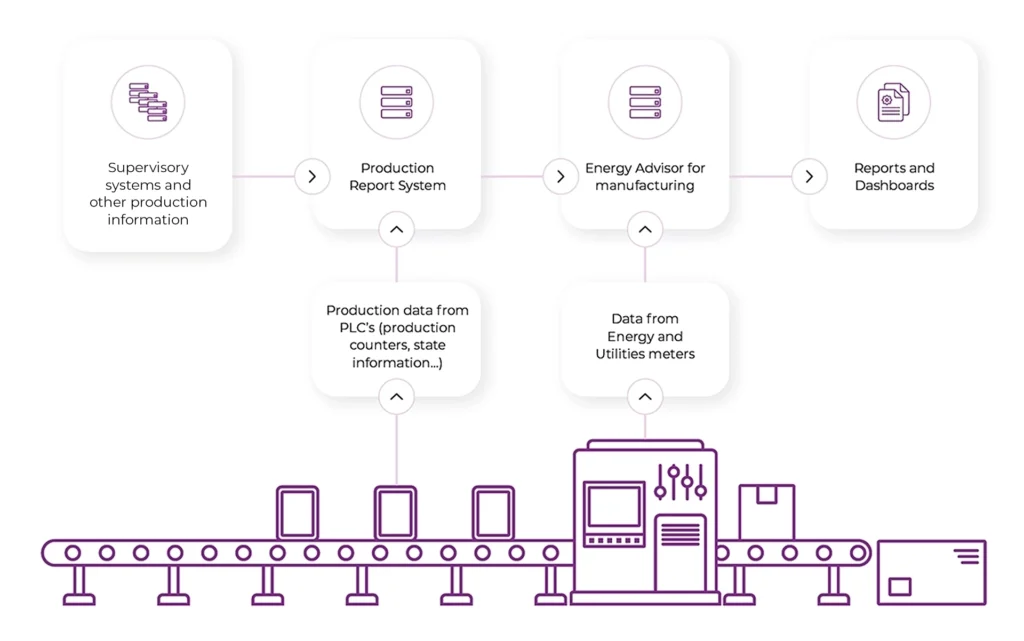

This is exactly what an Energy Management System (EMS) is built for: a set of processes, equipment, and technology designed to optimise energy through smart controls and automation, enabling real-time monitoring, data analysis, and visualisation without disrupting existing infrastructure.

A typical energy management system consists of four layers: sensors and meters (data capture), control systems (integration with machines and plant signals), analytics software (KPIs, baselines, anomalies, forecasting), and a user interface (dashboards and reporting). Automated control systems in an EMS adjust energy-consuming devices based on commands received by the analytics software. Without this end-to-end structure, improving energy performance becomes slow and error-prone especially when data must be manually collected from separate utility monitoring and production systems, increasing effort and maintenance costs.

TT PSC’s goal was to deliver a solution tailored to the client’s needs: an application that not only monitors and analyses utilities, but also ties them to production context and the digital twin.

The system feeds metering data into the corresponding digital twin, totalises services, and calculates defined intensities and utility consumption providing stable, customer-critical KPIs such as total media consumption per quantity of final product.

In practice, modern EMS platforms can reduce energy bills by 15%–30% by eliminating waste and shifting loads to cheaper off-peak times while also supporting sustainability efforts by tracking environmental impact and enabling more sustainable practices. Integrating energy saving measures into the overall EMS strategy is essential for achieving both cost savings and environmental goals.

The Energy Advisor solution is to be initially piloted at one customer’s plant for optimisation, but the application architecture is ready to be rolled out to additional plants with minimal changes.

Energy Advisor for manufacturing architecture

Energy Advisor – Example Use Case

The Energy Advisor was implemented to give full, real-time visibility into energy and utility consumption across manufacturing operations. By connecting production data with energy usage, the solution enabled the plant to move from reactive reporting to active optimisation.

What happened in practice:

- Real-time monitoring of electricity, gas, water, steam, and compressed air

- Energy analysis by product, production line, and machine group

- Automatic detection of abnormal consumption and inefficiencies

- Alerts triggered when operational thresholds were exceeded

- Data-driven actions introduced by operations and maintenance teams

Outcome:

Energy data became an operational asset—supporting faster decisions, reduced waste, and measurable efficiency improvements (results presented on the graphic).

What is the main function of EMS?

The main functions of an Energy Management System are:

- Collecting energy data

- Monitoring energy usage in real time

- Analysing energy performance

- Identifying inefficiencies and anomalies

- Optimising energy consumption

- Managing peak demand and tariffs

- Supporting compliance and reporting

- Tracking carbon emissions

Key processes in manufacturing energy management

A robust energy management system supports repeatable processes that deliver continuous improvement in energy performance.

Data collection and monitoring

Meters and sensors capture real-time electricity, gas, steam, and compressed air. The energy management system automates collection so data quality supports analysis and audit.

Analysis and benchmarking

The energy management system turns raw readings into KPIs and baselines. This improves energy efficiency by highlighting the biggest drivers and fastest wins.

Anomaly detection

Alerts identify spikes, leaks, and abnormal runtime so teams can reduce energy waste before it becomes cost or downtime.

Optimisation and control

Scheduling, setpoints, and load shedding help manage peak demand. When integrated with production systems, the energy management system protects output while improving energy efficiency.

Reporting and continuous improvement

The energy management system generates audit-ready reports on energy performance, cost savings, and carbon emissions, supporting internal reviews and external reporting.

By embedding these processes into daily operations, manufacturers can create a culture of energy efficiency that delivers sustained reductions in energy usage and costs.

Implementing Energy Management Systems

When deployed as ISO 50001 PDCA, the EMS becomes a continuous improvement loop: baseline → action → verification → scale. Audit-ready reporting becomes a by-product of daily operations, not a separate reporting project. This supports reducing operational costs and energy costs by making optimisation measurable and repeatable.

Step-by-step: How to implement an Energy Management System

1) Define scope, objectives and compliance requirements

Start by defining what the EMS should deliver: cost reduction (e.g. £/ton, peak demand), operational constraints (quality, throughput) and emissions visibility (Scope 1 and 2).

At this stage, confirm regulatory obligations such as ESOS, SECR or ISO 50001 alignment, including reporting scope and audit expectations.

2) Establish an energy baseline through an audit

Conduct a structured energy audit to understand how electricity, gas, steam, compressed air and HVAC are used across lines, shifts and processes.

This step identifies significant energy uses, inefficiencies and sets baselines and KPIs such as kWh/ton, £/batch and peak kW events.

3) Design the measurement and data architecture

Define what needs to be metered, where sub-metering is required and how data will be collected, synchronised and governed.

Clear data standards, time alignment and audit trails are essential to ensure the EMS is reliable, scalable and audit-ready.

4) Select the right Energy Management System

Choose between an off-the-shelf EMS and a tailored solution.

Standard platforms can be quicker to deploy, but manufacturing environments often benefit from systems that reflect production structure, batch logic and machine-level KPIs such as energy per product or per shift.

5) Install, integrate and pilot the system

Deploy meters, sensors and control integrations, then connect the EMS with production systems and building management systems where relevant. Run a pilot on one line or site to validate data quality, KPI logic and user workflows before scaling across the plant or multiple sites.

6) Optimise, automate and continuously improve

Use the EMS to identify quick operational wins and drive long-term optimisation through scheduling, load shifting and automated control. Continuously track performance, verify savings against baselines and extend the system to renewables, additional sites or advanced optimisation use cases.

Adopting modern energy monitoring services often delivered as Monitoring as a Service (MaaS) can accelerate Energy Management System implementation by improving compliance and cost visibility, while delivering positive ROI within 6–12 months without upfront capital expenditure.

Common energy management mistakes in manufacturing

Most failed energy initiatives in manufacturing share the same root causes.

- relying on utility bills

- no production context

- no ownership of KPIs

- one-off projects

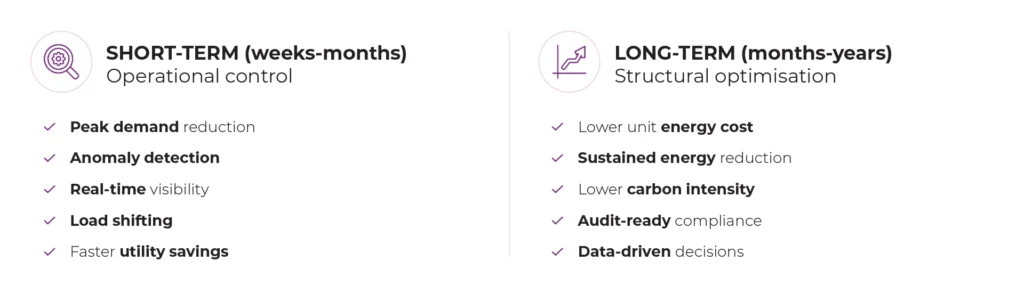

Key benefits from an energy management system

An EMS supports both quick operational wins and long-term structural optimisation.

What is the main function of EMS?

The main functions of an Energy Management System are:

- Collecting energy data

- Monitoring energy usage in real time

- Analysing energy performance

- Identifying inefficiencies and anomalies

- Optimising energy consumption

- Managing peak demand and tariffs

- Supporting compliance and reporting

- Tracking carbon emissions

Key processes in manufacturing energy management

A robust energy management system supports repeatable processes that deliver continuous improvement in energy performance.

Data collection and monitoring

Meters and sensors capture real-time electricity, gas, steam, and compressed air. The energy management system automates collection so data quality supports analysis and audit.

Analysis and benchmarking

The energy management system turns raw readings into KPIs and baselines. This improves energy efficiency by highlighting the biggest drivers and fastest wins.

Anomaly detection

Alerts identify spikes, leaks, and abnormal runtime so teams can reduce energy waste before it becomes cost or downtime.

Optimisation and control

Scheduling, setpoints, and load shedding help manage peak demand. When integrated with production systems, the energy management system protects output while improving energy efficiency.

Reporting and continuous improvement

The energy management system generates audit-ready reports on energy performance, cost savings, and carbon emissions, supporting internal reviews and external reporting.

By embedding these processes into daily operations, manufacturers can create a culture of energy efficiency that delivers sustained reductions in energy usage and costs.

Implementing Energy Management Systems

When deployed as ISO 50001 PDCA, the EMS becomes a continuous improvement loop: baseline → action → verification → scale. Audit-ready reporting becomes a by-product of daily operations, not a separate reporting project. This supports reducing operational costs and energy costs by making optimisation measurable and repeatable.

Step-by-step: How to implement an Energy Management System

1) Define scope, objectives and compliance requirements

Start by defining what the EMS should deliver: cost reduction (e.g. £/ton, peak demand), operational constraints (quality, throughput) and emissions visibility (Scope 1 and 2). At this stage, confirm regulatory obligations such as ESOS, SECR or ISO 50001 alignment, including reporting scope and audit expectations.

2) Establish an energy baseline through an audit

Conduct a structured energy audit to understand how electricity, gas, steam, compressed air and HVAC are used across lines, shifts and processes. This step identifies significant energy uses, inefficiencies and sets baselines and KPIs such as kWh/ton, £/batch and peak kW events.

3) Design the measurement and data architecture

Define what needs to be metered, where sub-metering is required and how data will be collected, synchronised and governed. Clear data standards, time alignment and audit trails are essential to ensure the EMS is reliable, scalable and audit-ready.

4) Select the right Energy Management System

Choose between an off-the-shelf EMS and a tailored solution. Standard platforms can be quicker to deploy, but manufacturing environments often benefit from systems that reflect production structure, batch logic and machine-level KPIs such as energy per product or per shift.

5) Install, integrate and pilot the system

Deploy meters, sensors and control integrations, then connect the EMS with production systems and building management systems where relevant. Run a pilot on one line or site to validate data quality, KPI logic and user workflows before scaling across the plant or multiple sites.

6) Optimise, automate and continuously improve

Use the EMS to identify quick operational wins and drive long-term optimisation through scheduling, load shifting and automated control. Continuously track performance, verify savings against baselines and extend the system to renewables, additional sites or advanced optimisation use cases.

Adopting modern energy monitoring services often delivered as Monitoring as a Service (MaaS) can accelerate Energy Management System implementation by improving compliance and cost visibility, while delivering positive ROI within 6–12 months without upfront capital expenditure.

Common energy management mistakes in manufacturing

Most failed energy initiatives in manufacturing share the same root causes.

- relying on utility bills

- no production context

- no ownership of KPIs

- one-off projects

Key benefits from an energy management system

An EMS supports both quick operational wins and long-term structural optimisation.

| Benefit | Operational impact in manufacturing |

|---|---|

| Lower total production cost | Energy is managed as a production variable, reducing unit cost (£/ton, £/batch) without lowering output. |

| Lower utility and electricity bills | Tariff awareness, load shifting and peak demand control reduce avoidable charges. |

| Energy consumption reduction (10–30%) | Waste elimination and optimisation of high-load processes across shifts and lines. |

| Anomaly detection and loss prevention | Early identification of abnormal usage prevents energy waste, downtime and quality issues. |

| Higher media efficiency | Improved compressed air, steam, water and gas performance through targeted optimisation. |

| Automated monitoring for compliance | Audit-ready energy and carbon data supports ESOS, SECR and ISO 50001. |

| Automated control and optimisation | Setpoints, schedules and loads are adjusted automatically to stabilise demand. |

| Lower carbon footprint | Energy use is linked to emission factors, enabling measurable Scope 1 and 2 reductions. |

An Energy Management System delivers value on two levels: immediate operational control and long-term structural optimisation. The difference is illustrated below.

Environmental impact and energy resources in manufacturing

In manufacturing, energy and emissions are operational variables: tracking Scope 1–2 alongside production KPIs (e.g., kg CO₂e/unit) is what turns sustainability targets into daily control.

Implementing a robust energy management system (EMS) is essential for companies aiming to address these challenges head-on. An effective EMS provides the tools and insights needed to monitor, analyse, and optimise energy usage across all areas of the plant. By identifying inefficiencies and areas of excessive consumption, manufacturers can take targeted actions to reduce energy consumption, cut operational costs, and minimise their environmental footprint.

A comprehensive energy management system empowers organisations to implement energy management strategies that directly reduce greenhouse gas emissions and energy waste. Through real-time monitoring and data-driven decision-making, manufacturers can optimise energy usage, ensuring that every kilowatt-hour is used efficiently and sustainably. This not only supports compliance with environmental regulations but also enhances operational efficiency and long-term competitiveness.

Ultimately, integrating an energy management system into manufacturing operations is a proactive step towards sustainable growth. It enables companies to balance the demands of production with responsible energy management, reducing both energy costs and environmental impact while supporting broader sustainability and corporate responsibility goals.

Energy Management Systems in UK manufacturing: cutting carbon footprints

In UK manufacturing, an energy management system has moved from “nice-to-have reporting” to a practical enabler of meeting sustainability targets because the UK’s Net Zero objective is embedded in law and drives expectations on how industry measures and reduces emissions.

In the UK context, energy management is shaped not only by cost pressure but also by regulatory and Net Zero obligations. A broader, manufacturing-focused overview of how Energy Management Systems support UK organisations including compliance, reporting and long-term optimisation.

A well-implemented Energy Management System links energy flows to production (lines, shifts, batches), so reducing greenhouse gas emissions becomes an operational KPI rather than a year-end estimate. Source: Climate Change Act 2008 (2050 Target Amendment) Order 2019.

For manufacturers, the biggest “first step” is getting reliable Scope 1 and 2 visibility. Integrated Energy Management System can calculate Scope 1 (direct fuel combustion on-site) and Scope 2 (purchased electricity/heat/steam/cooling) using metering, fuel data, and standard emission factors – creating audit-ready outputs that support UK reporting expectations and internal governance. Integrated systems in EMS track Scope 1 and 2 emissions, which is essential for meeting Net Zero targets.

This directly supports sustainability efforts by making carbon footprint and environmental impact measurable at the same granularity as operational performance. Source: UK Environmental Reporting Guidelines incl. SECR (2019 PDF).

From a “norms and schemes” perspective, Energy Management System data also helps plants demonstrate structured improvement. Under the UK Energy Savings Opportunity Scheme (ESOS), organisations can use alternative compliance routes such as an ISO 50001-certified energy management system – so an EMS supports continuous improvement cycles and evidence collection across existing infrastructure without disrupting key processes.

That accelerates sustainable practices (standardised monitoring, targets, reviews) while simultaneously lowering energy spend. Source: UK ESOS compliance guidance (GOV.UK).

Where manufacturing is energy- and carbon-intensive, the business case becomes even clearer: the UK ETS applies carbon pricing to heavy industry, so cutting fuel use and electricity demand reduces both operating cost and exposure to carbon costs.

EMS-driven optimisation helps enhance efficiency and improve productivity by reducing variability (abnormal peaks, idle loads, unstable utilities), while keeping energy performance aligned with output. The most common optimisation targets in energy management literature are energy system optimal sizing and the maximum power generated by renewable energy sources. Source: UK ETS policy overview (GOV.UK).

An Energy Management System supports the transition to renewable energy by providing the control logic and visibility needed to integrate on-site generation and storage, align loads with availability, and reduce reliance on fossil-based supply directly lowering carbon footprint and emissions. By optimising sources such as solar, wind or hydrogen, an EMS helps manufacturers remain competitive while improving energy efficiency and supply reliability. Evidence from the IEA shows that structured energy management (including ISO 50001) delivers around 11% average energy savings in the first years, translating into lower emissions and stronger CSR outcomes in manufacturing.

Summarise

Energy efficiency is rapidly becoming a strategic priority for manufacturers, yet it remains one of the least fully exploited areas of operational improvement. As energy costs, volatility, and reporting requirements increase, manufacturers can no longer rely on aggregated invoices or isolated optimisation initiatives. This is why understanding ’what is Energy Management System’ has become essential to achieving measurable, repeatable energy and cost savings. By providing real-time visibility, operational context, and structured energy control, an Energy Management System lays the foundation for solutions such as Energy Advisor – turning energy data into actionable insight and sustained business value.

Glossary

What is EMS?

EMS (Energy Management System) is a combination of software, meters, and management processes used to monitor, analyse, and control energy consumption across manufacturing operations. It helps organisations reduce energy costs, improve operational efficiency, and meet sustainability and regulatory requirements by turning energy data into actionable insights.

Industrial energy management systems (IEMS)

EMS built for industrial facilities (manufacturing plants, refineries) where high-frequency data, production context, and OT integration are required.

Energy information system (EIS)

A (often cloud-based) layer that collects and analyses gas and electricity usage data, typically used to consolidate energy data and reporting across sites.

Building management systems (BMS)

Systems that monitor and control building services (e.g., HVAC, lighting). In manufacturing, they’re commonly integrated so building loads can be coordinated with production loads.

Demand response systems (DRS)

Mechanisms that shift or reduce electricity usage during peak periods to lower peak-related charges and support grid stability.

Energy storage systems (ESS)

Storage technologies (e.g., batteries, flywheels) that capture energy off-peak and release it when demand or prices rise, supporting peak shaving and resilience.

Power quality

Electrical conditions (voltage events, power factor, harmonics) that affect stability, downtime risk, and operating costs.

Peak demand

The highest short-term power draw (kW) in a period; peak kW often drives demand charges more than total kWh.

Baseline vs actual variance

The % difference between expected (baseline) energy use and actual energy consumed for a given line/product/shift context.

Carbon intensity

Emissions per unit of output (e.g., kg CO₂e/unit or kg CO₂e/ton), connecting energy use to carbon footprint and environmental impact.

Scope 1 and Scope 2 emissions

Scope 1: direct on-site emissions (e.g., fuel combustion). Scope 2: indirect emissions from purchased electricity/heat/steam/cooling.

ISO 50001 (PDCA)

A standard that frames an EMS as continuous improvement using Plan–Do–Check–Act: define objectives and baselines, implement actions, verify results, and standardise/scale improvements.

Energy management program

A structured programme that turns KPIs into routines targets, actions, verification, and continuous improvement—so improvements are repeatable rather than ad-hoc.

Power grids

The electricity transmission and distribution network that supplies plants; constraints or peaks on power grids influence tariffs, demand response events, and operational planning.