Streamlining Automotive Manufacturing Processes with PTC MPMLink: Understanding Windchill

Optimizing automotive production processes and managing complex supply chains present several challenges in the automotive industry. As the automobile industry advances, particularly with digital twin technology, automakers are seeking more efficient and agile manufacturing solutions to remain competitive in a fast-changing market. The historical evolution of motor vehicles has significantly impacted the automotive industry, especially with the development of mass production techniques and the global shift in manufacturing dominance during the 20th century. With digitalization on the rise and Industry 4.0 principles in play, automakers are exploring innovative ways to change their operations.

A powerful solution for process optimization in automotive manufacturing

MPMLink, which stands for Manufacturing Process Management Link, is a vital part of PTC’s Windchill PLM suite. MPMLink, a module within the Windchill product line, enables the transformation from eBOM, sBOM, or rBOM and facilitates the creation of process and control plans. It then connects Windchill with ERP and other enterprise systems, providing comprehensive visibility into the production process. By integrating data from various sources, MPMLink helps enhance efficiency for automobile manufacturers and reduce costs through configuration, integration, and process automation, thereby optimizing business processes.

Product lifecycle management (PLM) plays a crucial role in improving processes across various industries by ensuring real-time data analysis and collaboration throughout the product’s lifecycle.

TT PSC, a leading provider of PLM and PTC Windchill services has vast experience in implementing MPMLink for its customers in the automotive industry. TT PSC’s use cases further demonstrate how powerful MPMLink is when it comes to optimizing production processes.

Managing the Production Process and Collaboration with PTC

Managing the production process in the automotive industry requires the involvement and cooperation of multiple teams. Collaboration with PTC in the context of the Windchill MPMLink tool enables not only data management but also process planning. This system allows for the documentation of the process plan, making it easier to manage individual production steps. As a result, collaboration with production becomes more efficient, allowing for better control over task progress.

Windchill MPMLink Overview [CLICK]

Business benefits of MPMLink in product lifecycle management

Enhanced operational efficiency

MPMLink enhances resource allocation through the streamlining of production planning and scheduling utilized by automotive manufacturers, thereby optimizing resource allocation and utilization for process optimization. This results in the elimination of bottlenecks, reducing downtime during the production of products, and increasing overall efficiency.

Data analysis plays a crucial role in managing production processes, enhancing visibility and efficiency in the product design process among all business stakeholders.

Cost reduction

By optimizing material usage and minimizing scrap rates or rework costs, manufacturers can significantly reduce waste material usage. This is made possible by MPMLink’s inventory management capabilities, which allow for more efficient material usage. Ultimately, this results in enhanced productivity and cost savings across the entire manufacturing process.

Accelerated time-to-market

The implementation of MPMLink enables faster product development cycles, which can be achieved through improved change management processes and process improvement. By reducing the production process planning effort, automotive manufacturers can minimize time to market for new products and variants, giving them a competitive advantage over their competitors in the industry.

See also: Solutions that help us introduce companies to Industry 4.0

Technical aspects of MPMLink implementation with digital twin technology

Configuration of MPM modules in Windchill

MPMLink offers configurable MPM modules on Windchill that can be easily adapted to meet the specific needs of automotive manufacturing. This enables manufacturers to automate their processes and optimize them, as they can now create production workflows, procedures, and rules.

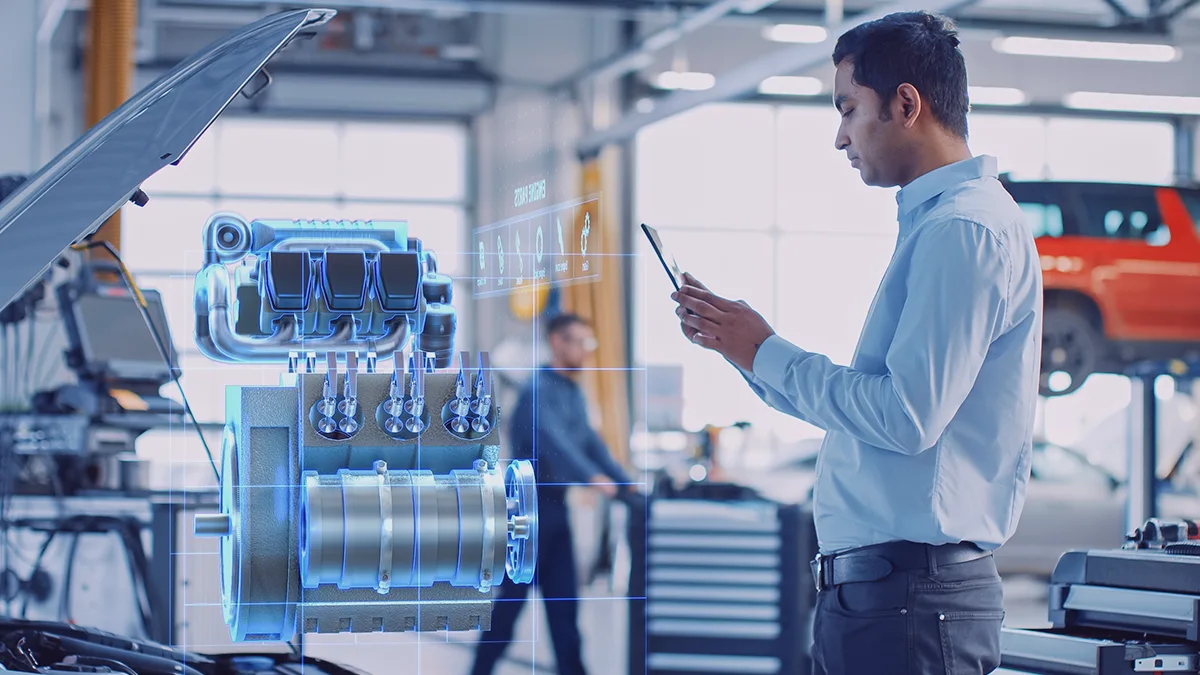

Leveraging Digital Twins for process automation

MPMLink enables the transformation of eBOM (Engineering Bill of Materials) into various BOM types, creating digital twins – virtual replicas of physical assets used in production. This digital twin technology facilitates enhanced design processes and real-time data analysis to improve vehicle safety. This process includes:

- Creating process plans with work instructions that are connected to CAD data.

- Generating visualizations that can be used in augmented reality (AR) scenarios.

These steps lead to the following benefits:

- Car manufacturers can simulate and optimize production activities before implementation, allowing for proactive improvements.

- Increased work quality, even for less experienced workers, thanks to AR visualizations.

- Enhanced predictive maintenance, reducing unplanned machine failures and increasing equipment utilization rates.

Furthermore, work steps can be utilized in IIoT (Industrial Internet of Things) on the digital shop floor for measurement and quality assurance. This comprehensive approach allows car manufacturers to significantly increase production efficiency and quality.

MPMLink also enhances product development processes by connecting product information and processes, driving agile development and helping companies bring innovative products to market more efficiently.

Integration with existing ERP and PLM systems

MPMLink’s integration of Windchill, ERP, and other enterprise systems into a unified platform ensures seamless data exchange between these platforms. This integration eliminates the silos of product, process, and production-related information that can arise in siloed systems.

TT PSC’s expertise in MPMLink implementation for the automotive industry

Transition Technologies PSC has successfully implemented MPMLink based on its previous experience in the automotive sector, streamlining key processes such as automating tasks and enhancing workforce efficiency. For instance, Transition Technologies PSC was engaged by Liebherr, one of the world’s leading manufacturers of machine tools and automation systems, to enhance the ability to integrate additional locations into your PLM environment, reducing time to value and increasing quality at the same time. Also other OEMs leveraged TTPSCs experience in this area.

The significance of product data management in fostering global collaboration within concurrent design environments cannot be overstated. A secure and highly integrated system supports multi-CAD functionalities, streamlining the management of product data.

Summary

PTC Windchill offers transformational opportunities for automakers seeking more efficient means of managing their own plants, including those producing commercial vehicles. It ensures competitiveness for all concerned, while allowing vehicle manufacturers to obtain maximum benefits derived from using MPMLink to enhance their production, reduce costs, and quicken product introduction.

One of the significant challenges in the industry is manual data entry, which can lead to bottlenecks and inefficiencies in sales order processing and product lifecycle management. Automating data capture and management can improve speed, reduce errors, and enhance overall efficiency in business processes.

As the millennial generation continues to evolve, it is essential for them to embrace new ideas like MPMLink to succeed in the future.

We also recommend: