How Unified Namespace breaks down data silos in industrial data management

Manufacturing companies are producing more data than ever before. Machines, sensors, ERP, MES, SCADA, and IoT platforms generate constant streams of data every second. Yet despite these large volumes, many organizations still struggle with industrial data management, leaving information trapped in silos and disconnected across departments, control systems, and production sites. This article explains why traditional data practices fail in Industry 4.0 and how a unified approach helps manufacturers overcome data silos and strengthen operational processes. Implementing a Unified Namespace provides a single source of truth, enabling real-time data accessibility and seamless integration across all systems.

The challenge of industrial data management in modern manufacturing

Modern factories are complex industrial environments where multiple technologies converge. ERPs track resources, MES manages production processes, SCADA supervises automation, and IoT sensors generate time series data on machine health, energy use, and safety. Each of these layers produces valuable insights – but often in different formats, at various speeds, and in different places.

Effectively managing data and operations is essential to optimizing factory performance and achieving sustainability.

The result?

- Fragmented visibility: leadership lacks visibility into the full context across industrial operations.

- Manual workarounds: operators and engineers spend time reconciling raw data instead of using it for analysis.

- Delayed insights: reporting is too slow to improve production efficiency or enable predictive maintenance.

According to McKinsey, poor data management in the industrial sector can reduce productivity by as much as 20–30%. Gartner predicts that by 2026, 70% of organizations in asset-intensive industries will double their investments in industrial data management solutions and system integration to overcome these challenges.

The price of data silos in industrial operations

Breaking down silos is not only a technical issue — it directly affects performance, expenses, and competitiveness.

- Missed opportunities – Without efficient industrial data management, organizations cannot optimize production processes or utilize assets fully.

- Higher costs – IDC estimates that poor reporting and fragmented data management can increase IT/OT expenses by 15–20% annually.

- Slower decisions – Managers lack timely insights to make informed decisions, reducing responsiveness and efficiency.

- Barriers to innovation – AI, advanced analytics, and digital twins all require unified, high-quality data.

To overcome these challenges, organizations need a solution that addresses data integration, asset management, and enables to use of the data, including an easy way to enable AI-driven insights for effective industrial data management.

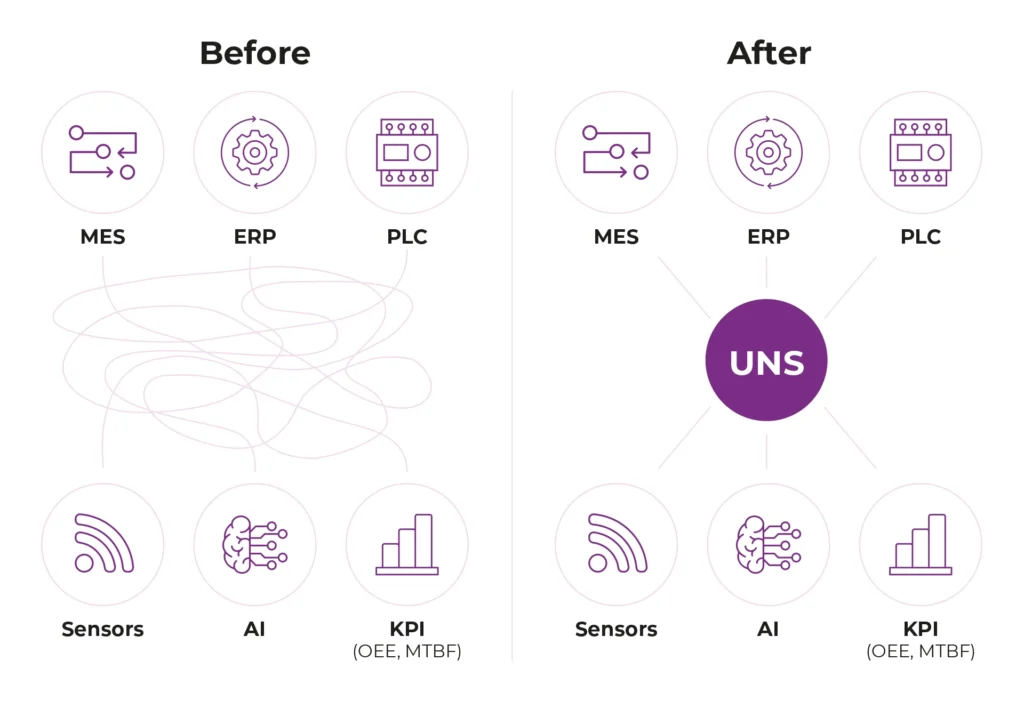

Why traditional data management falls short in Industry 4.0

For decades, manufacturers relied on point-to-point system integration: ERP connected to MES, MES to SCADA, and so on. While this solved short-term demands, it created a fragile web of entangled connections that is expensive to maintain and hard to scale.

Limitations include:

- High integration costs – each new machine or application requires custom engineering.

- Inconsistent formats – legacy control systems often produce raw data incompatible with enterprise applications.

- Limited scalability – expanding plants or introducing new technology means rebuilding integrations.

- Restricted access – decision-makers must log in to multiple environments to collect operational data.

In addition, process data integration remains a significant challenge, making it difficult to achieve effective process optimization and operational excellence. This fragmented environment also affects performance-measurement tools – for example, even the best OEE applications struggle to produce reliable insights without consistent, real-time data, a challenge explored in our guide How to Choose the Right OEE Software.

This slows down digital transformation, raises costs, and prevents businesses from reaching the full potential of industrial automation, advanced analytics, and artificial intelligence.

Comparison of Industrial Data Integration Approaches

| Approach | General Description | Advantages | Limitations |

|---|---|---|---|

| Point-to-Point Integration | Each system is directly connected to other ones (e.g., PLC → SCADA → MES → ERP) using custom, one-to-one links. | – Simple in small environments – Proven in traditional ISA-95 architectures | – High integration costs – Poor scalability – Fragmented data and delayed reporting |

| Enterprise Service Bus (ESB) | A central data “bus” mediates communication between systems (MES, ERP, SCADA), standardizing messaging formats. | – Decouples systems (no point-to-point dependencies) – Supports real-time messaging | – Requires consistent data models – Lacks unified context – Limited support for high-frequency sensor data streams |

| Data Lake | A large repository for storing raw data from across the enterprise — mainly for offline analytics and historical reporting. | – All data in one place – Suitable for analytics and machine learning – Can store data in any format | – Not real-time – No context or unification – Not suitable for real-time control of production |

| Unified Namespace (UNS) | A centralized, contextual data layer based on a publish/subscribe model (e.g., MQTT), aggregating all live data into a common, structured space. | – Real-time data with full context – Shared data language – Scalable and lower integration costs over time | – Requires namespace design and governance – Cultural/organizational shift in IT/OT – Higher initial effort and learning curve |

From data silos to a Unified Namespace in data management

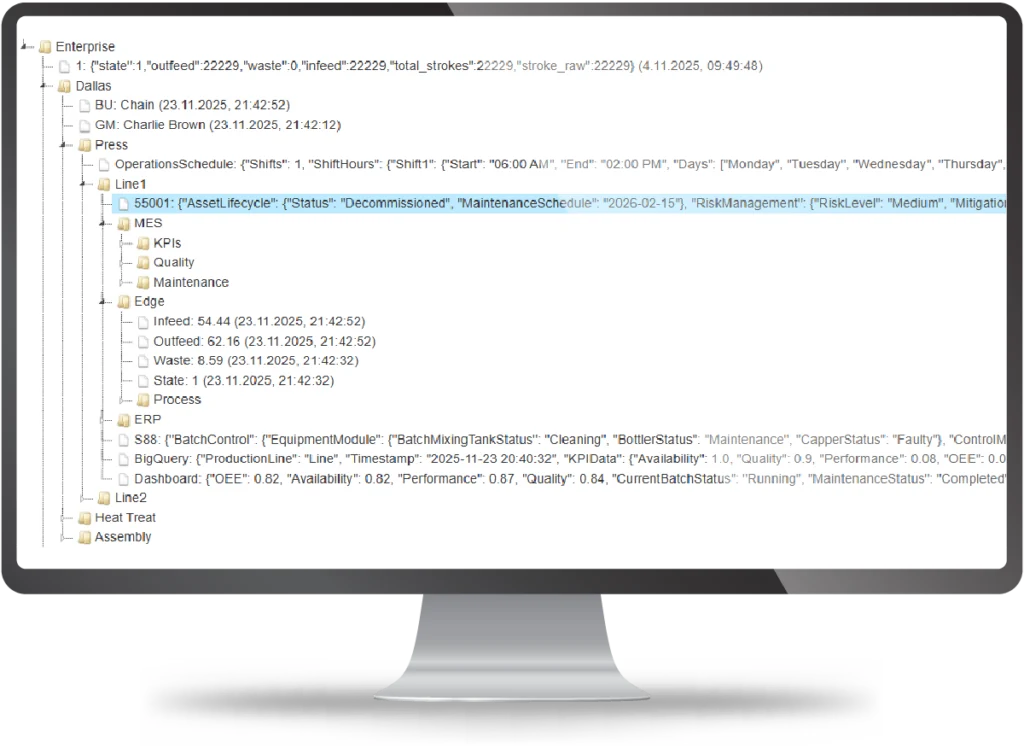

Manufacturing leaders are asking: “How can we manage industrial data more efficiently and generate actionable insights?” Unified Namespace gathers data from machines, systems, and applications into one central, organized layer, giving everything a common “language.” The plant serves as the central hub for industrial activities, data management, and digital transformation initiatives, making it essential to unify and streamline data flows.

Translating this into technical language: a Unified Namespace enables flexible data collection by streaming information from machines, systems, and enterprise applications into a single, structured layer that standardizes formats and context. This creates a flexible integration hub where IT and OT systems interoperate in real time, eliminating fragmented point-to-point connections.

For a deeper architectural explanation, including core design principles and typical implementation patterns, see what is Unified Namespace.

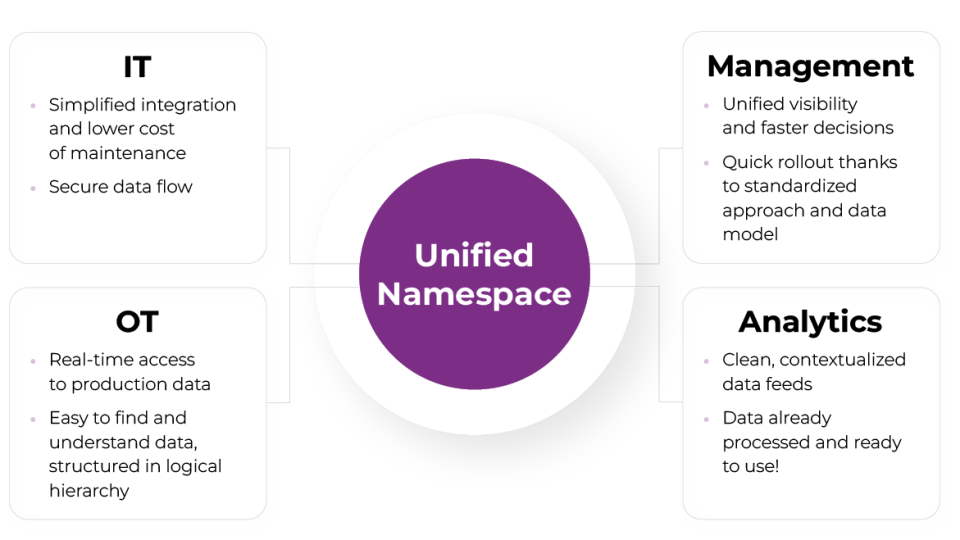

Benefits:

- Standardized system integration across industrial applications.

- Real-time access to operational data for operators, engineers, and decision makers.

- Stronger governance of raw data to prevent errors and compliance risks.

- A foundation for predictive maintenance, machine learning, and sustainability goals.

How advanced data management principles reinforce the value of Unified Namespace

Modern industrial data platforms highlight several capabilities that significantly strengthen the business impact of a Unified Namespace. One of the most important is building a trusted data foundation — a single, reliable layer where contextualized information is collected, enriched, and shared across the organization. UNS naturally supports this approach by eliminating inconsistencies, standardizing formats, and ensuring that all teams operate on the same version of the truth.

Three pillars that align directly with the Unified Namespace architecture:

- Collect and enrich data — UNS enables high-volume, real-time data collection from multi-vendor systems and adds the context needed for analysis.

- Visualize insights in meaningful context — once unified in a single namespace, data becomes easier to explore, trend, and compare, allowing teams to detect anomalies and make informed decisions faster.

- Share data securely across stakeholders — UNS provides a consistent structure that can be exposed to operators, engineers, managers, and partners without duplicating integrations.

Another key advantage is scalability from edge to cloud. Unified Namespace supports architectures where data flows seamlessly from edge devices to enterprise applications and cloud analytics, allowing manufacturers to expand capabilities as their operations grow. This makes it easier to unify not just production lines but entire facilities and multi-site environments.

Finally, UNS bridges the gap between engineering data (design, specifications, documentation) and operations data (performance, maintenance, quality), enabling teams to collaborate effectively across the full lifecycle of industrial assets. Companies adopting advanced industrial data management practices report measurable outcomes such as reduced engineering hours, fewer operational errors, and faster decision cycles — all benefits that UNS helps achieve by providing a robust, future-ready data ecosystem. The power of human-centered decision-making and automation within UNS further enhances operational efficiency and delivers deeper data-driven insights.

What manufacturers need to implement a Unified Namespace

To successfully adopt a Unified Namespace, manufacturers should start by understanding their current systems and ensuring they have reliable connectivity to machines and applications — typically through PLCs, SCADA, historians, or IoT gateways capable of publishing data. The company must also define a clear data model (topics, naming conventions, structure) to ensure consistent functionality, and identify priority data sources to address first. Implementation effort depends on system complexity, but typically involves configuring data collection endpoints, setting up an MQTT broker or Sparkplug B-compliant infrastructure, and mapping all data streams into a unified structure. Once the foundation is set, teams can gradually expand UNS coverage across production lines, creating a scalable and maintainable data architecture that strengthens industrial data management and supports future digital initiatives.

Real-world case study of Unified Namespace

1. Unified Namespace for Smarter Recipe Management in FMCG

One of the world’s largest food and brewery producers partnered with TT PSC to modernize recipe management across European facilities. By integrating an IoT platform with a Unified Namespace, the company unified data flows between MES, ERP, and automation systems, improved traceability, and reduced waste caused by outdated formulas. This approach helped eliminate costly recipe errors — a known industry risk highlighted by high-profile recalls.

Explore the full case: Unified Namespace example in action for smarter recipe management in FMCG

2. Distributed control on an SMT line powered by Unified Namespace

On an SMT assembly line, researchers implemented a heterarchical distributed control architecture supported by UNS. By connecting stations such as OMS, IOI, and MRS through a publish/subscribe model, they improved monitoring, resource utilization, and error detection. Simulations showed higher OEE and greater flexibility compared to traditional Industry 3.0 lines.

Source: revista Observatorio de la Economía Latinoamericana, 2024

3. Unified data exchange for the maritime industry

In the maritime sector, data was scattered across ports, vessels, and service providers. A Unified Namespace was proposed as a shared data layer, enabling real-time exchange of standardized information across the cluster. This improved collaboration, compliance, and decision-making — giving the entire ecosystem a competitive edge and demonstrating the value of UNS beyond manufacturing environments.

Unlock the full potential of Industry 4.0 with Unified Namespace

Reaching the next level of operational excellence requires more than just collecting data — it demands the ability to analyze data in real time across machines, systems, and teams. Unified Namespace (UNS) enables this by aligning operational technology with information technology, creating a common data layer for visibility, speed, and scale — and strengthening industrial data management across the entire production environment.

Research from Integrate.io shows that organizations adopting advanced industrial data management vendors gain measurable results — faster decision-making, greater agility, and significant cost savings.

With the complexity of manufacturing increasing, UNS is emerging as the foundation for scalable, future-ready digital ecosystems, leading to significant improvement in operational efficiency.

With the complexity of manufacturing increasing, UNS is emerging as the foundation for scalable, future-ready digital ecosystems, leading to significant improvement in operational efficiency. When paired with advanced tools such as OEE software and production monitoring and energy-focused platforms like Energy Advisor for Manufacturing, UNS becomes an even more powerful enabler — providing the real-time, contextualized data these systems need to deliver accurate insights, optimize resource usage, and support continuous improvement across the entire production lifecycle.