An Energy Management System UK: A practical guide for manufacturers

If you’re running a manufacturing facility in the UK, here’s what you’re up against – and why having a robust Energy Management System UK in place is quickly becoming non‑negotiable.

Your electricity costs are 4 times higher than what US manufacturers pay. Yes, four times. That’s not a typo – it’s the UK industrial reality.

The good news? A proper Energy Management System pays for itself in 12-24 months. Not years down the line – we’re talking about ROI you can actually see and measure.

Who needs this most? If you’re in food processing, chemicals, metals, or automotive – basically any energy-intensive sector – you already know your energy bills are painful.

The regulatory side: You’re dealing with ESOS audits every 4 years, annual SECR reporting, and the Climate Change Levy. It’s not optional – it’s compliance.

Here’s the opportunity: Between November and February, there’s something called the Triad period. Get your demand-side response right during these peak windows, and you can slash 15-30% off your annual electricity costs. For large energy users, that’s serious money back in the business.

Why UK Manufacturers Are Under Pressure

Let’s be honest: running a manufacturing facility in the UK right now means juggling multiple challenges at once. Energy prices keep swinging, costs keep climbing, regulations keep tightening, and Net Zero targets aren’t getting any more flexible.

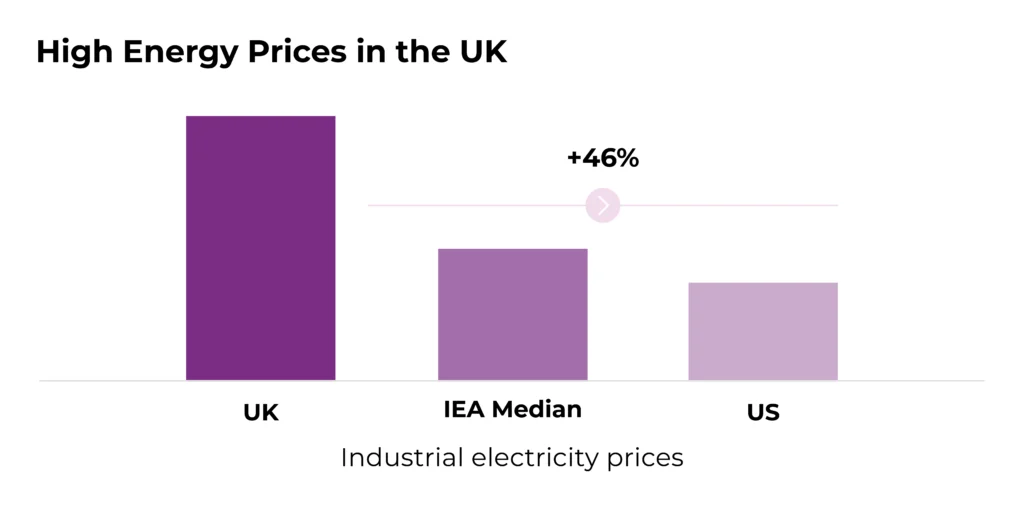

The Office for National Statistics has tracked how energy costs hammered UK businesses from 2021-2024. The numbers are stark: in 2023, the UK reported the highest industrial electricity prices among 24 countries in the International Energy Agency. UK prices were 46% higher than the IEA median – and roughly four times higher than the United States and Canada.

That’s not just a cost inconvenience – it’s an existential threat for energy-intensive sectors. Manufacturing output in industries like basic metals and petrochemicals has dropped by one-third since early 2021, reaching the lowest levels in over 30 years. High energy costs aren’t just eating margins – they’re shutting down production lines.

An Energy Management System (EMS) enables manufacturers to manage energy consumption as an operational variable rather than a static overhead. By structuring and analysing energy data from across manufacturing operations, EMS supports efficiency improvements, regulatory compliance and long-term energy performance management.

Modern energy management systems act as a central control unit for energy flow, enabling UK manufacturers to reduce energy wastage, control peak demand and improve energy performance without compromising production.

UK energy market context: why energy management matters

1. Energy prices are a strategic risk for UK manufacturers

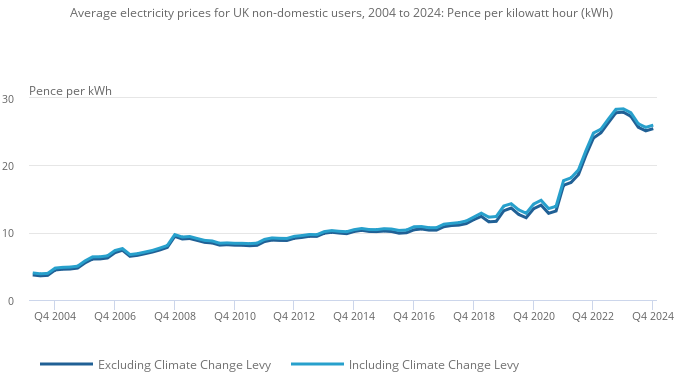

Source: DESNZ – Gas and electricity prices in the non-domestic sector

UK manufacturers face structurally high and volatile electricity tariffs and gas prices. Rising peak demand charges, fluctuating power consumption and complex pricing models from energy providers make energy usage increasingly difficult to control without dedicated energy management software.

Indicative indicators illustrating energy price pressure in UK manufacturing:

| Indicator | UK manufacturing context | Why it matters |

|---|---|---|

| Industrial electricity prices | ~46% above IEA median | Higher baseline operating costs |

| Price volatility | Significant year-to-year fluctuations | Difficult long-term planning |

| Peak demand charges | Increasing share of electricity bills | Penalises unmanaged load profiles |

2. Energy costs impact global manufacturing competitiveness

High energy consumption and inefficient energy monitoring increase unit production costs and reduce margins. Energy-intensive sectors are particularly exposed to uncontrolled electricity consumption, inefficient heating systems and poorly managed air conditioning loads, weakening their ability to compete and invest.

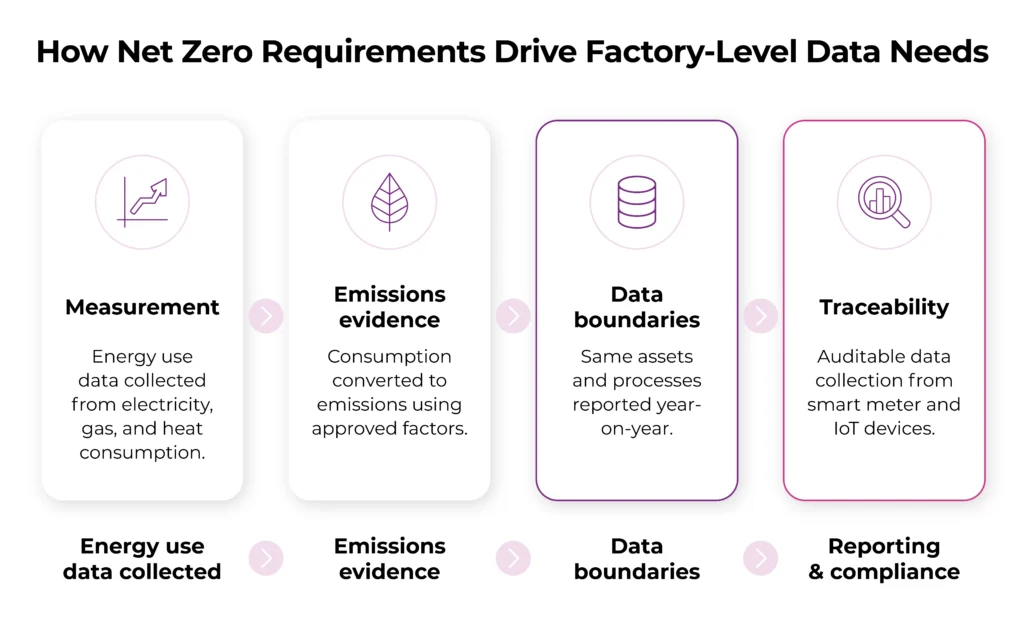

3. Net Zero targets require better energy data

Meeting Net Zero targets and supporting UK industrial decarbonisation requires manufacturers to accurately track energy use, carbon emissions and emissions data across Scope 1 and Scope 2. High-quality energy data and carbon data are now essential for decarbonisation planning, sustainability management, regulatory reporting and board-level decision-making.

As a result, Net Zero commitments translate into concrete data requirements at factory level, where energy usage must be measured, traced and evidenced with a high degree of accuracy.

4. Net Zero data requirements at factory level

To meet sustainability goals and ensure regulatory compliance, manufacturers must manage energy data with precision and consistency.

| Net Zero requirement | Factory-level implication | Why high-quality energy data is required |

|---|---|---|

| Measurement of energy use | Monitoring electricity, gas and power consumption at asset and process level | Emissions calculations depend on accurate energy consumption |

| Emissions evidence | Converting energy use into carbon emissions using approved factors | Incomplete data undermines credibility |

| Consistent data boundaries | Same meters, assets and processes year-on-year | Enables comparison of energy consumption trends |

| Data traceability | Auditable data collection from smart meters and IoT sensors | Required for energy audit and compliance |

| Demonstration of improvement | Measurable reduction in energy usage | Proof of optimising energy and saving money |

5. UK compliance requirements: ESOS and SECR

UK manufacturers are subject to two key regulatory frameworks governing energy and carbon reporting: the Energy Savings Opportunity Scheme (ESOS) and Streamlined Energy and Carbon Reporting (SECR). Together, they set clear expectations around data quality, consistency and auditability.

Energy savings opportunity scheme (ESOS)

ESOS requires large UK organisations to undertake a comprehensive energy audit every four years. The scheme focuses on identifying energy efficiency opportunities across operations and is intended to support long-term reductions in energy consumption. The programme also includes a series of implementation phases with defined deadlines, which can help organisations stay on track and maintain momentum. These include:

Key ESOS requirements include:

- Mandatory energy audits every four years

- Identification of inefficiencies and energy wastage

- Coverage of electricity, gas, fuel, transport and process energy

Streamlined energy and carbon reporting (SECR)

SECR introduces annual reporting obligations for energy use and carbon emissions. It places emphasis on transparency, consistency and comparability of data over time.

Key SECR requirements include:

- Annual disclosure of energy consumption and carbon emissions

- Consistent, comparable year-on-year data

- Reporting of electricity consumption, gas use and associated emissions

Climate Change Levy (CCL) and tax relief through CCAs

The Climate Change Levy is a UK tax on energy delivered to non-domestic users, adding directly to electricity and gas costs. Manufacturing organisations in energy-intensive sectors may be eligible for Climate Change Agreements (CCAs) – voluntary agreements with the Environment Agency that provide up to 90% relief from CCL in exchange for meeting sector-specific energy efficiency targets.

Beyond ESOS and SECR reporting requirements, UK manufacturers face direct energy taxation through the Climate Change Levy (CCL) – a tax on energy delivered to non-domestic users designed to incentivise energy efficiency and support UK decarbonisation goals.

CCA compliance requires:

- Demonstrable improvements in energy efficiency relative to baseline

- Regular reporting of energy performance to the Environment Agency

- Auditable energy data to support target achievement claims

For manufacturers with CCAs, an Energy Management System is essential to track performance against targets, maintain eligibility for tax relief, and avoid significant cost increases if CCA status is lost.

Implications for UK manufacturers

Both ESOS and SECR significantly increase pressure on UK businesses to professionalise energy data management. Fragmented data, estimates and manual reporting are no longer sufficient to meet regulatory expectations.

As a result, rising energy costs, competitive pressure and Net Zero obligations mean that UK manufacturers can no longer manage energy through disconnected data sources or periodic reporting alone. What is required is a structured approach that turns energy data into a controllable operational asset and supports ongoing compliance, performance management and decision-making.

Why manufacturers need a new approach to energy management

In many manufacturing organisations, teams store energy data across meters, spreadsheets, invoices and disconnected energy providers. This fragmentation prevents them from clearly understanding energy flows, peak demand, process-level consumption, or the true drivers of energy costs. The challenge intensifies in environments with energy-intensive processes such as compressed air, thermal processing, refrigeration, batching, or continuous production lines, where operating conditions cause significant demand fluctuations.

As described in 5 steps to increase energy efficiency for Manufacturers, manufacturers improve efficiency most effectively when they apply a structured, data-driven approach rather than isolated actions.

Without a structured energy management system, organisations cannot effectively:

- Optimise energy consumption

- Identify inefficiencies and detect anomalies

- Control air conditioning and heating systems

- Manage peak demand and electricity tariffs

- Track emissions and maintain compliance

Modern Energy Management Systems address these challenges by providing real-time monitoring, automated optimisation and anomaly detection. As a result, organisations enable continuous improvement instead of relying on reactive cost control.

What is an Energy Management System (EMS)?

An Energy Management System (EMS) is a digital management system designed to collect, structure and analyse energy data directly from manufacturing environments. In practice, this means capturing electricity, gas and power data from production machines, process equipment, utilities and supporting infrastructure using smart meters, machine-level sensors and IoT devices.

By aggregating and normalising data from machines, production lines and site utilities, an EMS enables manufacturers to understand how energy consumption relates to production activity, operating conditions and peak demand. Unlike basic energy monitoring tools, EMS systems provide the analytical foundation needed to optimise energy consumption, reduce operating costs and support informed decisions across manufacturing plants, multiple sites and data centres. Practical examples of how this data-driven approach translates into measurable savings are outlined in the article 5 Ways Manufacturers Can Reduce Energy Costs.

A more detailed, concept-level explanation of energy management systems — including how machine-level energy data is collected and used – is available in the article What is an energy management system, which explores the topic from a broader, technology-agnostic perspective.

The data foundation: Event-driven architecture and Unified Namespace

Modern Energy Management Systems increasingly rely on event-driven data architectures to handle real-time energy information from distributed manufacturing operations. At the core of this approach is the Unified Namespace (UNS) – a standardised method of organising and contextualising industrial data that enables seamless integration across complex, multi-site manufacturing environments.

Unlike traditional point-to-point integrations, a UNS-based EMS creates a single, coherent data layer where energy metrics from meters, sensors and equipment are automatically contextualised with production data, shift patterns and operational status. This architecture is particularly valuable for UK manufacturers operating brownfield sites with legacy SCADA systems, building management platforms and diverse equipment vintages, as it enables enterprise-wide energy visibility without requiring wholesale infrastructure replacement.

The technical implementation of UNS in energy management contexts typically uses lightweight protocols such as MQTT with Sparkplug B specification, providing a scalable, secure and standardised approach to industrial data exchange. This foundation supports the real-time monitoring, automated optimisation and compliance capabilities detailed in the following sections.

Key features of an energy management system

An Energy Management System (EMS) combines software and hardware to monitor, control and optimise how electricity is used across manufacturing facilities, commercial buildings or portfolios of sites.

Key EMS capabilities include:

- Real-time data collection from electricity meters, sub-meters, sensors and connected industrial or building systems, providing continuous visibility into energy usage and power consumption across sites and assets.

- Energy analysis and forecasting, using historical consumption data, electricity tariffs and operational constraints to predict energy demand, costs and future consumption trends.

- Automated and remote control of energy-intensive equipment and systems, including high-load industrial equipment such as compressors, HVAC, refrigeration and selected production assets.

- Tariff-aware optimisation, allowing automatic adjustment of energy usage to take advantage of multi-rate business energy tariffs, reduce peak demand charges and support load shifting.

- Intelligent optimisation algorithms supporting efficient use of on-site generated power and energy-intensive industrial utilities.

- Automatic alerts and anomaly detection, Automatic alerts and anomaly detection, notifying operational teams of abnormal energy usage, unexpected spikes, power quality issues such as poor power factor, or deviations from expected performance, enabling faster response and prevention of energy wastage and electrical inefficiencies.

- Continuous performance optimisation, supporting ongoing improvements that deliver more savings over time through sustained efficiency gains rather than one-off reductions.

Technologies enabled by EMS: DSR and VSD

Modern Energy Management Systems enable two particularly effective energy optimisation technologies:

Demand-Side Response (DSR) allows manufacturers to automatically adjust electricity consumption in response to grid signals, peak demand periods or high electricity tariffs. EMS platforms with DSR capabilities can reduce or shift energy-intensive processes during Triad periods or high-price windows, directly reducing TNUoS and DUoS charges while supporting grid stability.

Variable Speed Drives (VSD) control motor speed to match actual load requirements rather than running at constant full speed. When integrated with an EMS, VSDs on motors, fans, pumps and compressors can deliver 20-50% energy savings in typical manufacturing applications. The EMS monitors load conditions and adjusts VSD settings in real time to optimise energy consumption without compromising production.

Together, DSR and VSD represent concrete mechanisms through which an Energy Management System translates data into measurable energy savings and cost reduction.

You can explore additional details and examples of the system’s capabilities by visiting the Energy Advisor for Manufacturing page, where selected demo functionalities illustrate how the platform supports energy management in real manufacturing environments.

Who owns energy management in the UK manufacturing organisation?

In UK manufacturing organisations, responsibility for energy management typically spans multiple roles. Energy managers focus on energy consumption, performance and optimisation. Operations and engineering teams use EMS data to improve processes, control air conditioning and heating systems, and reduce power consumption. Finance and compliance teams rely on EMS outputs for energy bills, audits and regulatory reporting.

A successful Energy Management System UK creates a single source of truth that connects these functions and supports cross-functional decision-making. In manufacturing environments, this cross-functional view is particularly important where energy consumption is closely linked to shift patterns, production schedules and machine utilisation.

Typical industrial EMS implementation timeline and cost considerations (UK)

UK manufacturers typically implement an Energy Management System (EMS) through a phased process that balances regulatory requirements, operational complexity and cost control. The time and cost of implementation depend primarily on the size of the organisation, the number of sites and the complexity of power consumption.

| Phase | Duration | Deliverables |

|---|---|---|

| Energy audit | 4–6 weeks | Gap analysis, ESOS compliance assessment, baseline definition |

| Vendor selection | 2–4 weeks | RFP process, system architecture, integration plan |

| Hardware installation | 8–16 weeks | Meters (5–20 per site), sensors (15–50 per site), gateways |

| Commissioning | 4–8 weeks | Configuration, system testing, user training |

| Total | 18–34 weeks | Production‑ready EMS |

This structured approach helps organisations control implementation risk, understand total cost of ownership and ensure that the EMS delivers regulatory compliance, operational insight and long-term energy performance improvement.

Business case and ROI of energy management systems

UK manufacturers typically achieve ROI within 12-24 months where annual energy costs exceed £500,000, peak demand charges represent >20% of electricity bills (common with TNUoS/DUoS), and energy usage varies >30% between shifts or product changeovers.

TT PSC Case Study: International Food Manufacturer

An international food manufacturer improved energy efficiency and strengthened sustainability performance using Energy Advisor developed by TT PSC. By introducing automated energy data collection with real-time visibility, the organisation gained better control of energy consumption across operations – achieving measurable reductions in both energy costs and CO₂ emissions while supporting scalable, multi-site manufacturing.

Industry Benchmark: Caterpillar’s 44% Gas Reduction

Large energy-intensive manufacturers regularly achieve significant results with Energy Management Systems. Caterpillar reported a 44% reduction in gas consumption and 280 tonnes of CO₂ emissions cut over 12 months following EMS implementation.

Energy Management System vs Energy Monitoring vs SCADA

- Energy monitoring shows current energy use

- SCADA systems focus on real-time equipment control

- Energy management systems combine monitoring, analysis, optimisation and reporting

EMS platforms often integrate SCADA data but extend it with historical analysis, automated optimisation and compliance reporting.

ISO 50001 and Energy Management Systems

ISO 50001 provides a framework for continuous improvement in energy management. While an EMS is not ISO 50001 by default, energy management software is often essential to:

- Establish energy baselines

- Track performance indicators

- Demonstrate measurable improvement

- Ensure audit readiness

How to choose the right Energy Management System UK

When selecting an Energy Management System (EMS), manufacturers should assess the system not only from a functional perspective, but also in terms of its suitability for industrial operations. Energy Management Systems are most commonly adopted by large organisations and energy-intensive businesses, such as manufacturing companies, where energy consumption is material to operating costs and carbon emissions. By contrast, small businesses that are not energy-dependent and do not have substantial energy usage typically do not require the capabilities of an industrial EMS.

For manufacturing organisations, key selection criteria include:

- Scalability across multiple sites, production lines and assets, including the ability to consolidate energy data from geographically distributed plants

- Integration with industrial infrastructure, such as heating systems, air conditioning, compressed air, process equipment and EV charging where relevant

- Management of electricity tariffs and peak demand, particularly in environments with variable load profiles and high peak demand charges

- Automated optimisation with <5 minute response time to tariff changes or Triad warnings, real-time monitoring at 1-second granularity for critical assets, and integration with production scheduling systems (MES/ERP) to align energy usage with manufacturing plans.

- Support for energy audits, ESOS requirements, ISO 50001 alignment and ongoing regulatory compliance

- Extensibility and future-proofing, allowing users to easily expand the platform with additional capabilities such as water and wastewater monitoring, environmental KPIs, or integration with OEE features to provide richer operational context and deeper performance insights.

For industrial users, it is particularly important to select EMS solutions that are designed specifically for manufacturing environments and can be customised to site-specific processes, assets and data structures. Generic, building-focused systems often lack the flexibility required to reflect production variability, machine-level energy use and complex operational constraints.

The right Energy Management System enables long-term energy optimisation, sustained cost reduction and effective management of energy and carbon performance in complex industrial environments.

Future Energy Regulations and EMS by 2026

By 2026, UK energy regulations are expected to place stronger emphasis on:

- Data accuracy and traceability

- Integration of energy and carbon data

- Continuous improvement rather than one-off audits

Half-hourly settlement and granular electricity consumption data will further increase the importance of structured EMS systems.

Conclusion

An Energy Management System in the UK now serves as a core capability for manufacturing organisations responding to rising energy costs, tightening regulatory requirements and Net Zero commitments. By collecting, analysing and controlling energy data in a structured way, manufacturers use EMS to reduce costs, track emissions and drive continuous improvements in energy performance.

A well-designed energy management approach enables manufacturers to move beyond periodic reporting and actively manage energy as an operational variable. Using reliable, auditable data, they support efficiency improvements, track decarbonisation progress and achieve long-term sustainability objectives.

Energy management readiness checklist for manufacturers

Manufacturing organisations considering a more structured approach to energy management should be able to answer the following questions:

- Do we have reliable, consistent data on electricity, gas and other energy use at site, line or machine level, rather than relying solely on aggregated utility bills?

- Can we explain how energy consumption changes by shift, product or process, and how this impacts overall building performance and production efficiency?

- Are peak demand charges, electricity tariffs and load profiles actively managed in real time, or only reviewed retrospectively through monthly invoices?

- Is our energy and carbon data auditable and suitable for ESOS, SECR or ISO 50001 requirements?

- Can we demonstrate measurable improvements in energy performance and building performance year on year, supported by comparable baselines?

If these questions cannot be answered confidently, it is often an indication that energy is still managed through fragmented data sources rather than a structured Energy Management System.

Glossary: essential UK energy terms

Energy Management System UK

An EMS implemented in the context of the UK energy market and regulatory environment, including ESOS, SECR and Net Zero requirements.

ESOS (Energy Savings Opportunity Scheme)

A UK regulation requiring large organisations to carry out energy audits every four years to identify energy efficiency opportunities.

SECR (Streamlined Energy and Carbon Reporting)

A UK reporting framework requiring eligible organisations to annually disclose energy consumption, carbon emissions and energy efficiency actions.

ISO 50001

An international standard providing a structured framework for continuous improvement in energy performance, supported by measurable data.

Net Zero targets

UK commitments to reduce greenhouse gas emissions to net zero by 2050, requiring accurate measurement and management of energy use and emissions.

Scope 1 and Scope 2 emissions

Scope 1 covers direct emissions from on-site energy use, while Scope 2 covers indirect emissions from purchased electricity.

Peak demand

The highest level of electricity consumption over a defined period, often a key driver of electricity costs in the UK.

Electricity tariffs

Pricing structures applied by energy suppliers, including multi-rate tariffs that influence when energy is used.

Smart meters and sub-meters

Devices that measure energy consumption at site, building, line or machine level and provide the data foundation for EMS platforms.

Triad charges A UK-specific charging mechanism where the three half-hour periods of highest national electricity demand between November and February determine annual transmission network charges. Effective Triad management through demand reduction or load shifting can deliver significant cost savings for half-hourly metered manufacturing sites.

DUoS and TNUoS charges Distribution Use of System (DUoS) and Transmission Network Use of System (TNUoS) charges recover the costs of operating the UK’s electricity network infrastructure. Together they can represent 20-30% of total electricity costs and are heavily influenced by consumption patterns, making them key targets for EMS optimisation.

EnPI (Energy Performance Indicators) Quantitative metrics defined under ISO 50001 that measure energy performance relative to a baseline, enabling organisations to demonstrate measurable improvement over time and maintain compliance with energy management standards.

Demand-side response (DSR) A flexible approach to electricity consumption where manufacturers adjust energy demand in response to grid signals, price signals or peak demand periods, supported by automated EMS control to reduce costs and support grid stability.

Specific Energy Consumption (SEC) Energy consumed per unit of production output (e.g., kWh per tonne), enabling meaningful comparison of energy efficiency across different production volumes, product mixes and operating periods.

kWh and MWh Kilowatt-hour (kWh) and megawatt-hour (MWh) are the standard units for measuring electricity consumption used in energy billing, reporting and performance analysis, where 1 MWh equals 1,000 kWh.