How to choose the right OEE software – a complete quide

This blog post provides comprehensive guidance on how to choose the right OEE software, helping manufacturers navigate the decision-making process with best practices and expert insights.

When it comes to the digital transformation of the production area, OEE system is one of those tools that can really make a difference for the business. But picking the right one isn’t just about ticking off features from a list. It’s more about making sure the solution actually fits your manufacturing processes, meets compliance requirements, and can scale as the business grows.

I remember one of our clients joking that choosing the best tool felt harder than buying new production lines, because every manager had a different “must-have” on their list. In the end, the breakthrough came when they focused on what really mattered for each of the stakeholder’s group. For operations, it was production performance and targets. For maintenance – support to keep the equipment effectiveness of the machines high. For management, reliable data is needed to steer the business.

And don’t forget that for operators, it must be a seamless experience – not adding them a new workload and hassle, but simplifying, making understanding of the situation quick and supporting. Things like a user-friendly interface seem like an insignificant detail at first glance, but from the perspective of adoption among the crew, it can be crucial.

Why overall equipment effectiveness software matters for manufacturing

You know what’s tricky? A lot of losses in availability, performance, and quality just fly under the radar if you don’t keep an eye on them in a structured way. That Matec study (2019) showed exactly that.

The good news is that OEE – especially when combined with new technologies – helps uncover those hidden inefficiencies and gives you the data you need to build a real culture of continuous improvement. When making sure the solution actually fits your manufacturing processes, OEE monitoring software integrates directly into the manufacturing process to identify inefficiencies, reduce waste, and increase reliability. Overall equipment effectiveness is a key metric for evaluating manufacturing performance, and a good tool provides all the key performance indicators necessary for manufacturing operations.

It means you stop guessing why production targets slip and finally identify areas where to act first – whether that’s fixing frequent stoppages, improving speed, or tackling quality issues. OEE monitoring software serves as a specialized tool for tracking and analyzing machinery performance in manufacturing environments. On the factory floor, within the manufacturing environment, that translates into the ability to reduce waste, boost efficiency, and give teams more confidence in the numbers they rely on every day.

Why now? The bigger picture

- The OEE software market is set to nearly double from $67.5B in 2023 to $122.4B by 2028 (MarketsandMarkets).

- Digital transformation in manufacturing will reach $847B by 2030 (Mordor Intelligence). This is one of its key pillars. Learn more about our digital manufacturing solutions.

- Early adopters report 10–30% higher throughput and up to 50% fewer stoppages (SCW.ai / McKinsey).

- New tech like digital twins boosts overall equipment efficiency by up to 15% while cutting maintenance costs by 40% (StartUs Insights).

- Still, 42% of manufacturers haven’t started their digital journey (L2L).

Role of OEE in improving efficiency and reducing downtime

The solution tracks machine availability, performance rates, product quality, as well as machine performance and machine output, making it easier for any manufacturing business to assess operational performance, spot bottlenecks, and recurring issues on the production line. The Matec study showed that looking closely at such metrics helped one company pinpoint their biggest source of losses and take targeted action – boosting efficiency and cutting waste.

Instead of spreading resources thin, you can identify areas where action is required now. It means faster wins and less frustration in production. For those looking to boost operational performance, production monitoring with OEE provides actionable insights to drive continuous improvement.

Importance of real-time production monitoring

With OEE software, data flows in continuously from machines and sensors, with real-time data being collected. That means you’re not just looking back at what went wrong – you see machine performance and equipment effectiveness live and can step in before small issues snowball. The study highlighted how real-time monitoring and continuous monitoring support preventive and predictive maintenance, helping teams avoid unexpected stoppages. With predictive maintenance, you can avoid unplanned downtimes. predictive maintenance and how it supports manufacturing processes.

You spend less time firefighting breakdowns and more time keeping production stable, which gives both operators and managers more confidence in daily operations. Real-time dashboards further help by visualizing live performance metrics, making it easier for operators and managers to track KPIs, such as availability and downtime, as they happen.

Contribution to ROI and improvement

Every small boost in overall equipment effectiveness (OEE) adds up – higher throughput, better cost efficiency, and smarter planning, leading to improved operational efficiency. Research shows that structured metrics not only cut hidden losses but also guide decisions about investment and workforce allocation. As part of the OEE improvement process, addressing energy usage can play a significant role in reducing operational costs. Our Energy Advisor for Manufacturing is designed to help monitor and optimize energy consumption. Discover 5 ways manufacturers can reduce energy costs.

You can clearly show leadership how each improvement translates into ROI, proving that better efficiency is directly tied to achieving operational goals and stronger business results. Discover 7 ways manufacturers can reduce energy costs while improving efficiency.

Two main paths: off-the-shelf vs custom software

When it comes to OEE software, there are two main paths: off-the-shelf or custom-built. Before diving into pros and cons, here’s a quick checklist to guide your thinking. Be sure to consider the key factors that influence the selection, such as availability, performance, and quality:

- Do your manufacturing processes follow standard industry patterns, or are they highly specific?

- Is a fast rollout more important right now, or do you need room to grow long term?

- How tightly must it connect with your existing IT/OT setup?

- Will a simple dashboard do, or do you need advanced metrics tailored to your factory? Evaluate the key features, such as dashboard capabilities and metric customization.

Keeping these questions in mind will make it easier to see which approach is the better fit as you read on. Ultimately, choosing the right tool depends on these key factors and key features.

When considering deployment models, we can recognize:

- a SaaS solution

- on-premise

- hybrid

SaaS solution offers cloud-based accessibility, scalability, and simplified deployment compared to on-premise or hybrid options. It also make licensing easier.

Often, however, the manufacturing industry does not want production data to leave the industrial network, making on-premise the only viable option.

Off-the-shelf OEE software solutions

Benefits of ready-made OEE systems

- Quick deployment and fast ROI

- Lower upfront costs

- Pre-built integrations with MES, ERP, SCADA systems, and other systems

Limitations of standard solutions

- Limited flexibility for unique processes

- Vendor roadmap dependency

- Challenges with legacy compatibility

- Limited flexibility or integration challenges for on-premises deployment

Popular OEE Software Solutions in Europe and the USA

Evocon, HYDRA X, Epicor Advanced MES, Aptean Process Manufacturing OEE, Mingo Smart Factory, Raven.ai, GainSeeker Suite, TRACTIAN, Guidewheel, MaintainX, Fiix

Red flags: signs you’ve chosen the wrong OEE Software

Not every tool on the market will be a good fit. Here are three common warning signs that should make you stop and rethink your choice:

- Operators won’t use it – if the interface isn’t intuitive, the software will be ignored, no matter how powerful the features look on paper.

- Reports don’t add up – when the collected data isn’t accurate or consistent, trust disappears quickly, and managers go back to spreadsheets. The absence of detailed reports—such as downtime analysis, top loss tracking, and trend identification—can further undermine trust and hinder operational improvements.

- Integration drags on for months – if connecting to your ERP, MES, or legacy machines becomes a never-ending project, the ROI vanishes before you even get started.

Custom OEE Software (tailor-made approach)

When custom OEE software makes sense

- Complex or highly specific production processes, including the need to track and analyze individual components within discrete manufacturing, enhancing granularity and traceability

- Support for continuous processes

- Industry-specific compliance (pharma, aerospace, automotive)

- Need for deep integration with legacy IT/OT systems

- Currently used application is „outgrown” by your increasing requirements and need for flexibility

Key advantages of tailor-made solutions

- Full control over features and development roadmap

- Scalable architecture aligned with business growth

- Stronger alignment with security and compliance standards

- Ability to enhance productivity through tailored analytics and automation

- Tailored for scalability in your organization, across your plants

Potential challenges to consider

- Higher initial investment

- Longer implementation timelines

- Need for a trusted technology partner

Best OEE software: your decision checklist

Before you decide which OEE solution to go with, run through this quick self-check. It’ll help you figure out whether OEE software for you is something off-the-shelf or a custom build:

- How unique is my production?

Standard workflows may fit a ready-made tool, while special processes might need something tailor-made. - How fast do I need results?

If you want to get started next month, off-the-shelf might work. If you can wait longer, custom could be worth it. - How much can I invest now?

Lower upfront costs vs. bigger spend today for long-term scalability — which fits your plan? - How well do my current systems talk to each other?

Do you need smooth integration with ERP, MES, or legacy machines, or is your setup simple? Consider whether the solution can collect and analyze OEE data from all relevant sources. - Who will actually use it?

Operators may want a user-friendly interface; managers may care more about detailed OEE metrics and the ability to calculate OEE accurately. - What features are must-haves?

Do you need built-in root cause analysis to diagnose downtime or performance losses, or advanced reporting for continuous improvement? - What’s my long-term game plan?

Are you solving today’s issues only, or do you want something that grows with your manufacturing business?

Honest answers here will make it much easier to see what the best solution really looks like for your factory.

Next steps after choosing custom OEE software

If you’ve decided it has to be a custom solution — here’s what to do next

1) Lock your goals & success metrics

Write down the 2–3 problems you must solve and define success (baseline and target OEE metrics, downtime, first-pass yield). Why it matters: clear targets keep scope tight and prove ROI.

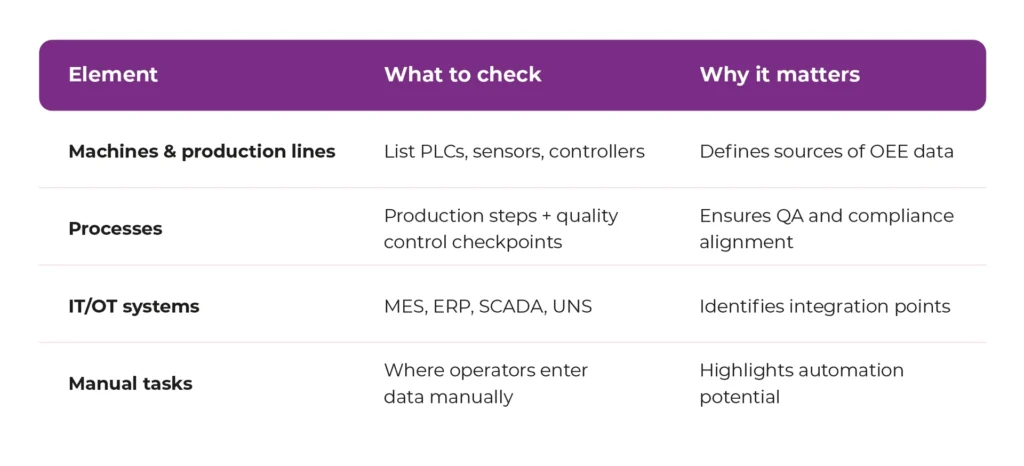

2) Map your process & data

Sketch key production steps, machines/PLCs, sensors, and where data lives (MES/ERP/SCADA/UNS). When mapping your manufacturing operations, be sure to include quality control steps and visual inspections as part of the process. Note gaps and manual steps on the shop floor. Why it matters: You’ll know exactly what to integrate and what to automate first.

2) Map your process & data

Add a mini checklist of what should be included in mapping:

You’ll immediately see where the biggest gains are and avoid underestimating integration work.

3) Prioritize an MVP

Pick one line/cell and 3–5 must-have features (e.g., automated data collection, live dashboards, top loss analysis). Park the “nice to haves.” Why it matters: faster time to value, less risk.

Example priority frame for an OEE MVP:

- ✅ Automated downtime data collection

- ✅ Real-time loss dashboards

- ✅ Analysis of top 3 loss categories

- ❌ Advanced predictive algorithms (later)

- ❌ Full integration with 5 other systems (later)

An MVP gives you proof of value in 2–3 months instead of waiting a year for the “perfect” system.

4) Draft the integration blueprint

List required protocols (OPC UA/DA, MQTT, Modbus), systems to connect (MES, ERP, CMMS), data model, and latency needs (edge vs cloud vs hybrid). Why it matters: prevents surprises when you plug IT and OT together.

In parallel, consider increasing efficiency without heavy investments by leveraging existing resources and improving workflows. Learn more in this article on optimizing production efficiency without additional investments.

5) Nail security & compliance early

Identify standards and controls (e.g., ISO 27001, FDA/EMA data integrity, audit trails, user roles). Why it matters: avoids costly rework and speeds up approval.

Compliance Requirements for OEE Software – USA

Industry | Key Regulations | What OEE Software Must Support |

|---|---|---|

Automotive | IATF 16949, ISO 26262, NHTSA | Data traceability, audit-ready reports, quality metrics |

Food & Beverage | FDA 21 CFR Part 11, FSMA | Batch traceability, electronic records, audit trails |

Defense & Aerospace | ITAR, DFARS / NIST SP 800-171, AS9100 | Secure data handling, controlled access, compliance evidence |

Pharmaceuticals & Medical Devices | FDA 21 CFR Part 11, cGMP, HIPAA | Batch traceability, electronic records, and audit trails |

Energy & Utilities | NERC CIP, OSHA | Critical infrastructure monitoring, worker safety compliance |

Chemicals | EPA Regulations, OSHA PSM | Emissions tracking, process safety monitoring |

Electronics & Semiconductors | IPC Standards, NIST Guidelines | Integration with MES, compliance with safety & material standards |

Compliance Requirements for OEE Software – Europe

Industry | Key Regulations | What OEE Software Must Support |

|---|---|---|

Automotive | IATF 16949, ISO 26262, EU Automotive Standards | Process quality metrics, traceability, safety compliance |

Food & Beverage | EC 178/2002, ISO 22000 | Transparent reporting, process documentation, and audit trails |

Defense & Aerospace | AS9100, EU Defence Procurement Directive (2009/81/EC) | Data integrity, validation, and electronic batch records |

Pharmaceuticals & Medical Devices | EU GMP Annex 11, MDR (EU 2017/745), GAMP 5 | Energy monitoring, resilience, and compliance with network security |

Energy & Utilities | NIS2 Directive, EN 50160, ISO 50001 | Energy monitoring, resilience, compliance with network security |

Chemicals | REACH, CLP, Seveso III Directive | Safety reporting, hazardous materials tracking |

Electronics & Semiconductors | CE Marking, RoHS, ISO/IEC 27001 | Compliance with product safety and information security standards |

6) Choose the reference architecture

Decide on cloud/edge/hybrid, storage, analytics stack, scalability, and high-availability requirements, backup/DR, and observability. Why it matters: your system will scale with production instead of becoming technical debt.

7) Turn needs into user stories

Capture stories for operators, supervisors, maintenance, and quality (e.g., “As an operator, I need a one-click reason code so we keep running”). Add user stories for quality control and visual inspections, such as: “As a quality manager, I need to track visual inspections and quality control checks to ensure product standards are met.” Why it matters: guarantees a user-friendly interface that fits real work.

Examples across different roles:

- Operator: “I need to enter downtime reasons with one click.”

- Maintenance: “I need an alert before vibration levels cross the threshold.”

- QA Manager: “I want a history of visual inspections linked to batch numbers.”

- Production Director: “I want to see OEE rolled up at the plant level in weekly reports.”

This ensures the system is not “just another IT tool” but real support for every role on the shop floor and in management.

8) Time-box a pilot (PoC)

Run on one line on the plant floor for 8–14 weeks with clear exit criteria (accuracy of overall equipment efficiency calc, alert precision, adoption). Why it matters: proves value before you roll out plant-wide.

9) Build the TCO/ROI model & rollout plan

Estimate build + integration + training + support; model savings from reduced downtime and better production performance; plan a phased rollout. Why it matters: aligns budget holders and keeps the program funded.

10) Evaluate vendors & technology partners (final step)

Use a simple scorecard to compare partners:

- Manufacturing fit: proven custom OEE/production monitoring in your industry, references you can call.

- Integration strength: deep IT/OT skills (PLC protocols, MES/ERP), data modeling, latency handling.

- Security & compliance: documented controls, audit features, validation support.

- Product quality: UX for the shop floor, reliability, performance SLAs.

- Delivery approach: agile, MVP first, clear roadmap and ownership of IP/custom code.

- Support & training: onboarding for operators and admins, response times, local presence.

- Value & transparency: clear pricing, measurable outcomes, co-created KPIs. Why it matters: the right partner accelerates results and reduces project risk from day one.

Not sure if off-the-shelf or custom is right for you? Let’s talk it through – claim your free consultation today.

Our approach to OEE software development

- Consulting first – you don’t need to know exactly what you want. We start by listening, analyzing your production setup, and then proposing the right OEE solution for your business. We rely on hundreds of delivered systems, to guide and suggest the best way.

- Proven + custom – we combine tested OEE frameworks with tailor-made solutions that truly match your production needs.

- Industrial know-how – years of experience in delivering manufacturing IT/OT solutions, with a deep understanding of the industrial environment, from the shop floor to enterprise systems.

- Flexible deployment – cloud, edge, or hybrid, depending on what works best for you.

- Custom fit – modules, tailored dashboards, and seamless integration with UNS, MES, ERP, and SCADA.

- Less paperwork – we cut bureaucracy to a minimum and stay agile in delivery.

- Expert team – dedicated specialists who know how to make technology work in real factories.

Final thoughts

At the end of the day, choosing OEE software doesn’t have to be rocket science. Off-the-shelf tools work great when you need speed and simplicity. Custom solutions shine when your processes are complex, compliance is strict, or you’re planning for long-term growth.

Don’t overthink it: the best OEE solution is the one that actually fits your factory, helps operators on the shop floor, and gives leadership the reliable data they need to drive decisions with confidence.