Sustainable development and ESG standards in the Automotive Industry thanks to PLM solutions

Sustainable development in the automotive industry is no longer just a trend, but a necessity driven by increasing regulatory requirements (ESG, EU Green Deal), consumer expectations, and pressure to reduce CO₂ emissions and implement a circular economy. A key tool supporting companies in this process are modern PLM (Product Lifecycle Management) solutions, which enable effective achievement of ESG goals and facilitate the green transformation.

Evolution of PLM tools in the context of sustainability challenges

PLM software, broadly speaking, has undergone significant evolution-from tools mainly for managing product data to comprehensive platforms supporting sustainable development. Transition Technologies PSC, as a global technology solutions provider, supports manufacturers in digital transformation, including meeting environmental standards. PLM systems offer functionalities that allow companies to achieve sustainability goals and move towards operating in line with the concepts of Industry 4.0 or Smart Factory. Advanced PLM software utilizes various technologies and integrate with solutions such as artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), and advanced data analytics. This elevates production processes to a whole new level, streamlining every stage of the product lifecycle: design management, new product development, advanced and in-depth data management, improved product development strategies, product quality enhancement, and predictive actions related to the supply chain or failure prediction. All of this is correlated with monitoring environmental indicators, which is why we now refer to Sustainable Industry 4.0 and Sustainable Smart Factory.

Challenges facing the automotive industry in sustainable development

- Regulatory compliance and the ability to verify environmental impact throughout the product lifecycle.

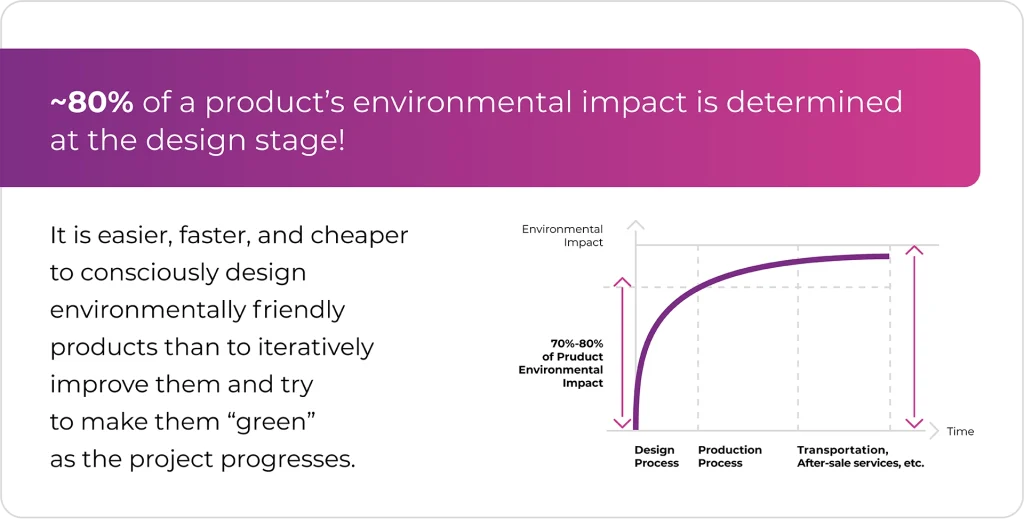

- Sustainable product design, i.e., precisely determining environmental impact already at the design stage.

- Considering environmental laws and standards during product compliance verification with legal and ecological requirements.

- Meeting customer expectations for sustainable products.

- Implementation of the Digital Product Passport.

- Efficient energy management in production processes.

Industry standards, environmental regulations, and the role of PLM tools

The automotive industry is subject to many rigorous standards and regulations aimed at ensuring safety, quality, and minimizing negative environmental impact. The most important include:

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) – EU regulations on chemicals, requiring identification and control of substances throughout the product lifecycle.

- RoHS (Restriction of Hazardous Substances) – limitation of hazardous substances in electronics and electrical equipment.

- ELV (End-of-Life Vehicles Directive) – directive on recycling end-of-life vehicles, requiring design for material recovery.

- WEEE – directive on waste electrical and electronic equipment, also covering electric and hybrid vehicles.

- CSRD/ESRS – new European sustainability reporting standards, requiring detailed ESG metric audits and reporting.

- EU Green Deal, Fit for 55 – European climate and environmental strategies, setting climate neutrality and zero-emission targets for new vehicles.

- Science-Based Targets (SBT) – scientifically validated emission reduction targets, increasingly required from suppliers by automotive corporations.

- ISO 9001, ISO 14001, ISO 26262 – standards for quality, environmental, and functional safety management.

PLM systems integrate these standards’ requirements into design, production, and product lifecycle management processes, automating reporting, compliance tracking, and documentation. This enables automotive companies to manage risk more effectively, respond quickly to regulatory changes, and build competitive advantage based on transparency and environmental responsibility.

The role of PLM Systems in sustainable automotive development

Advanced PLM systems are central platforms for managing product information at every stage-from concept, through design, market introduction, returns management, to end-of-life, i.e., disposal or recycling. In the automotive industry, PLM plays crucial role in integrating processes, data, and teams, enabling:

- Optimization of vehicle design for material and energy efficiency.

- Automation and standardization of processes, shortening product development time and reducing material losses.

- Cross-departmental and supplier collaboration, crucial for tracking material origins and emissions in the supply chain.

- Implementation of eco-design principles from the earliest product design stages.

- Rapid adaptation to changing regulatory requirements and market expectations.

PLM software as the foundation of sustainable design and production

Creating sustainable products in the automotive industry, despite challenges, environmental regulations, and compliance requirements, is not only possible but already being realized by technologically mature companies. These companies understand that modern digital solutions, implemented carefully and with employee involvement, are the only path to achieving „Sustainable Industry 4.0.” A recommended video series explains the Smart Factory concept and effective implementation: Smart Factory Explained

Below are solutions and practices enabling digital transformation in the context of ecoPLM implementation, along with examples from Schaeffler and MineMaster.

1. Integration of sustainable practices from concept to recycling

ecoPLM enables management of the entire product lifecycle, allowing for sustainable product design that considers environmental aspects from the outset. Centralizing data on materials, processes, and components allows companies to:

- Select materials with lower carbon footprints and higher recycling potential.

- Analyze the environmental impact of different design variants.

- Design products that are easier to repair, disassemble, and reuse.

2. Digital Twins and simulations

PLM supports the use of Digital Twins-virtual replicas of physical products, such as vehicles. They allow simulations and optimization before physical prototypes are built, enabling assessment of energy efficiency, material durability, and recycling potential, thus reducing physical testing, resource use, and development costs.

Compliance management and supply chain transparency

Regulatory and societal expectations for environmental and ethical responsibility in the automotive industry are rising. PLM systems play a key role by ensuring process transparency and effective risk management, particularly through:

1. Compliance automation and documentation

The automotive industry is subject to strict environmental and quality regulations. PLM automates compliance tracking (e.g., REACH, RoHS, ELV), stores necessary documentation, and enables quick report generation for audits and ESG disclosures.

2. Supplier transparency and collaboration

By integrating with supply chain management tools, PLM allows:

- Monitoring the origin of materials and components.

- Assessing suppliers’ environmental and social practices.

- Rapid response to risks related to non-compliance or supply disruptions.

This is crucial for implementing a circular economy and building trust with customers and partners.

Production process optimization and emissions reduction

Increasing requirements for decarbonization and resource efficiency drive automotive companies to implement innovative technological solutions throughout the product lifecycle. PLM systems enable identification of improvement areas and effective change implementation, including:

1. Energy efficiency and waste minimization

PLM allows analysis and optimization of production processes to reduce energy, water, and material consumption, lowering both costs and CO₂ emissions, as well as production waste.

2. Supporting the circular economy

PLM supports recycling initiatives, component reuse, and product design for disassembly and material recovery, maintaining compliance and achieving environmental and economic goals.

Benefits of PLM implementation

- Shortened product development time-automation of change and configuration management enables faster response to rapidly evolving market and strict regulatory requirements.

- Increased quality and safety-integrating quality management (QMS) with PLM allows quick detection and elimination of non-conformities and implementation of corrective actions.

- Better business decisions-advanced analytics and reporting in PLM support decision-making based on real data about environmental impact, costs, and risks.

Key benefits of ecoPLM:

- Improved CSRD reporting-ecoPLM provides the necessary data and tools to prepare reports compliant with the Corporate Sustainability Reporting Directive.

- Integrated carbon footprint calculation-enables easy calculation of overall carbon footprint and inclusion of this information in sustainable product design.

- Emissions management-detailed analyses enable effective management and reduction of emissions, especially Scope 3 (from the value chain).

- Sustainable industrial design-ecoPLM places eco-design principles at the core of product development, offering tools for selecting sustainable materials and assessing their environmental impact.

- Brownfield approach-leverages existing data and systems, using platforms like Thingworx Navigate to extend PLM capabilities with sustainability features.

Windchill PLM as the foundation of sustainable development

Windchill integrates data, processes, and teams at every product lifecycle stage-from concept, through design, production lines, to recycling. PLM processes support automotive companies in:

- Optimizing sustainable industrial design for material and energy efficiency.

- Automating and standardizing processes, shortening product development time and reducing material losses.

- Collaborating with suppliers, crucial for tracking material origins and emissions in the supply chain.

- Implementing eco-design principles from the product concept stage.

Success Story: Schaeffler – Accelerating development and Digital Transformation

Schaeffler, a global motion technology leader, implemented Windchill+ in the cloud to accelerate product development, improve collaboration, and ensure compliance with the latest ESG requirements. Moving to a cloud environment enables faster innovation, centralized product data management, and seamless integration with sustainability reporting tools.

CO₂ emissions reduction and supply chain optimization

PLM supports the green transformation by:

- Selecting suppliers with lower environmental footprints-PLM systems enable analysis and preference for suppliers meeting Science-Based Targets (SBT) and other sustainability standards.

- Optimizing logistics and production processes-real-time data analysis reduces energy, material use, and emissions throughout the value chain.

- Supporting the circular economy-PLM enables product design for recycling, reuse, and waste minimization, monitoring material and component flows throughout the vehicle lifecycle.

- Digitizing production processes-IIoT tools support remote monitoring and data collection, reducing travel needs and related emissions.

Success Story: Mine Master – Service documentation management in PTC Windchill

Mine Master Ltd, a Polish company from Wilków specializing in mining, construction, and tunneling machinery, worked with Transition Technologies PSC to implement PTC Windchill. This improved service documentation management, enabled better control over product lifecycles, and optimized resource use. Centralizing data in the PLM system allows the company to track the environmental impact of its machines and make design decisions considering sustainability.

Read the full story here: Mine Master: Service documentation management in PTC Windchill

Integrating PLM with other systems – The key to comprehensive sustainability management

Effective support for sustainable development requires integrating PLM with other enterprise systems, such as:

- ERP systems-coordinate resource management with design and production.

- MES (Manufacturing Execution Systems)-monitor production workflows and optimize energy consumption.

- IoT/IIoT platforms-provide data from devices and machines for precise monitoring of production and environmental parameters.

- Supply chain management systems-support the selection of sustainable suppliers and logistics optimization.

Transition Technologies PSC, a strategic PTC partner since 2005, has a team of over 700 technology specialists helping clients achieve business goals by promoting leading PTC technologies and implementing tailored solutions.

The future of PLM systems in automotive sustainability

Future trends in PLM for sustainable development include:

- Digital Product Passport-tools for creating and managing digital product passports with comprehensive information on composition, material origin, and environmental impact.

- AI in sustainable design-using artificial intelligence to optimize designs for environmental impact.

- Blockchain for material traceability-ensuring full supply chain transparency.

- Advanced carbon footprint analytics-more precise tools for calculating and reporting emissions throughout the product lifecycle.

You may also find this video interesting:

Summary

PLM systems are the foundation of the green transformation of the automotive industry. They enable optimization of design and production, and above all, effective management of environmental compliance, CO₂ emission reduction, supply chain transparency, and the implementation of circular economy principles. Transition Technologies PSC, with its advanced ecoPLM solution and experience in implementing PLM systems for leading companies-including in the automotive sector-provides comprehensive tools supporting sustainable development. Implementing these solutions allows automotive manufacturers not only to meet ESG requirements but also to build a competitive advantage in the era of sustainable development, where the green transformation becomes not just a regulatory requirement but a key factor for market success.

Want to know more? Read: