Unified Namespace example in action for smarter recipe management in FMCG

Manufacturers face fragmented systems and inconsistent data every day. In this real Unified Namespace example, those challenges are solved by turning scattered production data into one reliable, connected source of truth.

From shop floor to global operations in food & brewery with the IoT Platform

When one of the world’s largest food and brewery producers began modernizing its European operations, the focus was recipe management. Outdated systems made updating formulas, sharing data, and ensuring consistency across sites difficult.

The company’s products reach more than 180 markets worldwide, so flexibility and consistency were critical. To support this scale, it needed a recipe management system that could start small but grow across multiple sites while simplifying collaboration between manufacturing lines and teams.

The decision to work with TT PSC was based on a history of successful cooperation. Building on that trust, the new project became a natural step forward in the company’s digital transformation journey.

What ultimately demonstrated the solution’s value was the combination of in-depth discovery workshops, which built a deep understanding of the process and the ability to build a complete project, including integration with the controls layer to release recipes to production. The workshops allowed us—together with the Customer—to uncover hidden problems, outdated habits, and paperwork-heavy processes, especially around organizing data and managing legacy workflows. The project then showcased how these challenges could be addressed with modern enterprise applications, delivering tangible results to the management team. This way, they could clearly see the benefits of a digital solution without committing to a significant capital investment.

When old processes become a barrier to growth

In many manufacturing plants, long-standing systems still drive daily operations. Adapting recipes to changing market needs was time-consuming, data was scattered across different places, and every adjustment required manual effort. The legacy solution was not meeting maturing requirements and was not stable enough to ensure reliable operations.

For operators, this meant difficulty accessing the right information at the right time. For managers and engineers, it meant delays, higher costs, and a lack of flexibility. What was once seen as stable infrastructure had become a barrier to efficiency and growth. Machine data was expected to be available in real time so that it could be contextualized and shared with stakeholders across different departments of the organization.

The problem of gaining the newest technology

A practical story shows how risky this can be. In one plant in a different company, R&D approved an updated recipe for a seasonal product, but the packaging line ran the old version because teams worked in different software systems. Without a central repository or proper data governance, the wrong ratio was applied. The result? Pallets of end product were scrapped, weekend overtime was needed, and a customer complaint triggered an internal audit. This was the turning point when leadership saw the need to access data across MES, enterprise resource planning, and other plant systems to secure a connected manufacturing environment.

And this risk isn’t hypothetical:

- According to Brewer Magazine, Left Hand Brewing initiated a recall of nearly 20,000 cases of Milk Stout Nitro due to excessive carbonation caused by wild yeast — demonstrating how even non-safety-critical quality issues can result in large-scale recalls.

- According to Beer & Brewing, Left Hand Brewing destroyed or recalled about USD 2 million worth of beer and pursued legal action against their yeast supplier after contamination.

These examples confirm that even small recipe errors can escalate into waste, recalls, or reputational damage without unified systems. Strong data governance and integrated tools prevent such risks, creating a reliable flow from recipe design to production execution. Let’s return to our case. Analyzing the client’s operations enabled the precise identification of challenge areas.

Key challenges identified:

- Data scattered across many systems – production data stored in different places made it hard to get a full picture.

- Complicated access rights – unclear rules on who can see what created confusion and risk.

- Manual data collection – engineers had to pull information from machines and systems by hand, slowing work down.

- Limited reporting — available only per site, with no easy way to compare plants across regions; in many cases, requested reports could not be generated at all due to missing data.

- Weak traceability – hard to track products end-to-end, affecting sustainability and supply chain transparency.

- Poor visibility over time – difficulties in storing and using historical data for long-term insights and compliance.

Industrial IoT Platform and a real unified namespace example in action

The client’s digital transformation required more than just replacing software. It needed a common communication interface, a way to organize all the data consistently, and a universal language across the entire enterprise. To achieve this, the company turned to an Industrial IoT platform as the foundation for data acquisition and integration. The Industrial IoT platform supports common IIoT protocols, such as OPC UA, Modbus, or MQTT (message queuing telemetry transport), which are widely used for connecting industrial devices and systems. At the same time, it replaces static connections with centralized integration and a more dynamic, event-based approach.

The IoT platform provided:

- Flexibility to connect disparate systems

- The ability for systems to publish data in real time to the unified namespace

- Support for advanced real-time analytics

Digital transformation – the perfect match

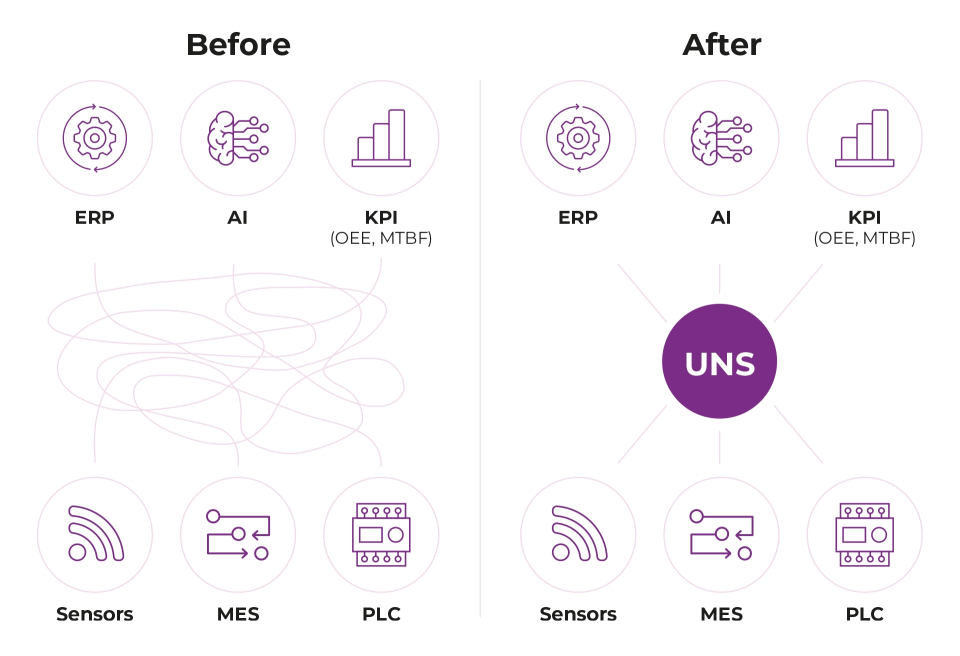

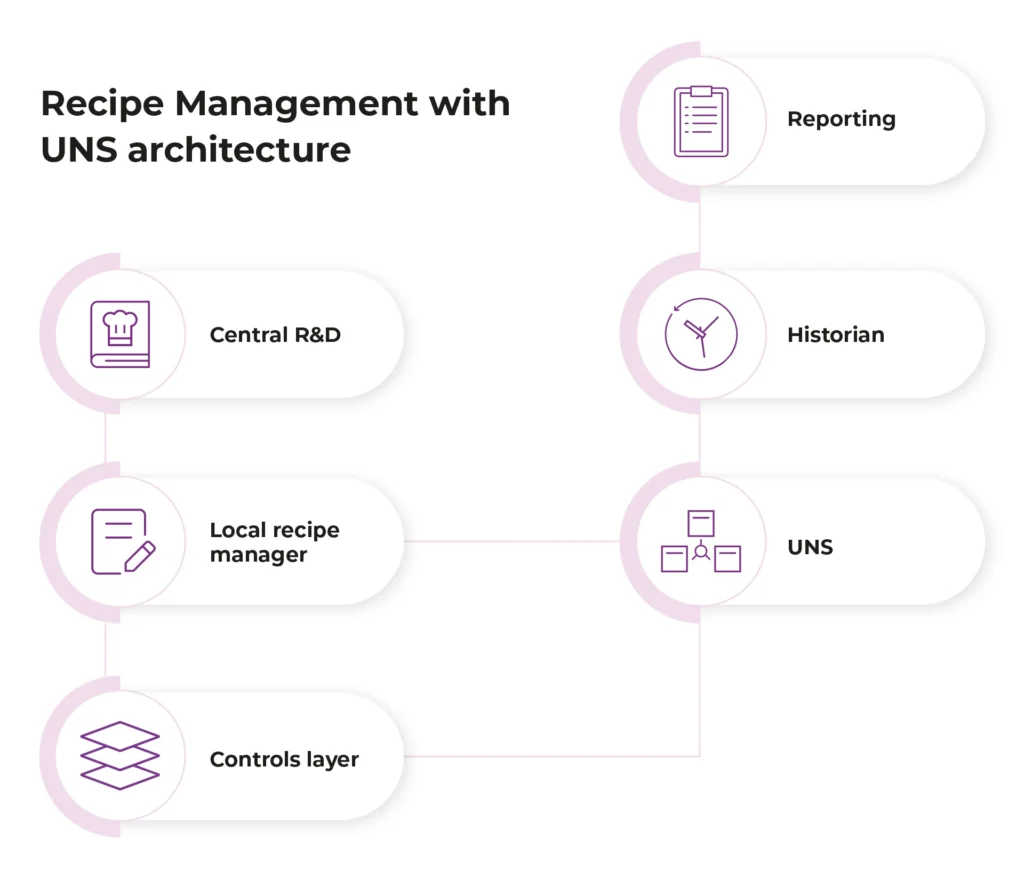

This is where the Unified Namespace (UNS) architecture came into play. Together with the Industrial IoT platform, a Unified Namespace created a scalable framework for managing industrial data.

An example like this shows how a Unified Namespace (UNS) architecture can serve as the backbone of industrial automation. The Unified Namespace works like a central library for production data – instead of information being locked in separate machines or systems, it is collected in one place, given common standards, and shared across the enterprise. A data broker, often based on MQTT, acts as the intermediary that facilitates efficient data transfer and communication between systems within the UNS. This approach makes it easier to connect MES, supervisory control (SCADA systems), and, in the future, ERP systems. To support compliance and long-term insights, the solution was complemented with a historian database for reliable storage and access to historical data.

Example:

For an operator, this means faster access to the right data without having to switch between multiple screens or systems. It also automates part of the workflow, enabling quicker decisions based on real-time data. For a manager, it means consistent, real-time insights across all sites, making it easier to compare performance, ensure compliance, and plan improvements. The UNS leverages an event-driven architecture to process and distribute large volumes of data generated by machines and sensors in real time.

What is a Unified Namespace structure?

A unified namespace architecture not only collects data but makes it usable enterprise-wide. It acts as a translator, enabling legacy devices and modern applications to communicate effectively. Data modeling ensures accurate publishing into the UNS structure, while standardized data encoding and formats guarantee seamless interoperability. Changes, like recipe updates, automatically propagate, reducing errors and providing a single source of truth for planning and improvement. UNS starts by publishing data from components to a centralized repository, creating a unified, accessible data environment.

Properly structured UNS data supports efficient sharing and integration throughout the organization, while also addressing ordering issues in data flow between the internal network and the DMZ, which previously caused security concerns.

Unified Namespace architecture

A Unified Namespace (UNS) architecture underpins modern industrial automation by uniting all data points from software and hardware into a single, organized framework. Using a hierarchical structure, it labels data consistently and makes it accessible enterprise-wide, breaking down silos and enabling free information flow across departments and manufacturing lines.

A good UNS implementation provides a universal language for diverse systems—legacy or modern—to communicate uniformly, „translating” various data formats. This streamlines communication, accelerates the digitalization journey, and simplifies integrating new technologies across locations.

Unlocking efficiency with a Unified Namespace and Industrial IoT Data Platform

By replacing fragmented connections with a unified system, our solution enables seamless, real-time data exchange between machines and software.

For the business, this brought:

- Less manual work – production recipes move automatically from central systems to local lines.

- More flexibility – local teams can make quick adjustments and speed up product launches.

- Better visibility – production data is organized and available in one place, in real time, integrated from different systems, such as ERP, SCADA systems, industrial automation systems, or data lakes.

- Standardization – unifying various data formats, common IIoT protocols under UNS structure.

- A foundation for the future – data can be used for advanced analytics, compliance, and AI. Industrial IoT Platform also integrates seamlessly with solutions such as OEE, Predictive Maintenance, Energy Advisor for Manufacturing, supporting energy efficiency and sustainability goals across sites.

As a result, fragmented and manual processes turned into a reliable system that supports daily operations and opens the door to further automation and innovation. The unified platform also supports integration with a wide range of software systems, including ERP and MES, to ensure end-to-end data flow.

From data points to business operations

With the Unified Namespace (UNS) living across the production line, everyday work became more intuitive and efficient. For example, an operator responsible for mixing a product now uses a modern interface to quickly load the right recipe, instead of checking multiple spreadsheets. At the same time, a plant manager can review batch reports in real time, supported by the company’s industrial automation system. By integrating data from the ERP system with the unified namespace, managers gain comprehensive insights into material information and production processes, enabling more informed decision-making.

Practical improvements included:

- User-friendly recipe management that reduces errors and saves time on the shop floor.

- Consistent data formats across different systems make it easier to analyze and share information.

- Easy access for decision-makers to data (both real-time and historical), strengthening business operations and planning.

This combination of tools and processes created a seamless flow of information across the enterprise network, proving how a Unified Namespace can turn data into business value. Our role was not only to provide the technology but also to apply business and manufacturing expertise, guiding the client through each stage of digital transformation with solutions grounded in real production needs. Effective UNS integration, facilitated by a data broker, was essential to achieving these outcomes, ensuring the Unified Namespace was successfully implemented within the client’s existing ERP and MES systems.

Data analysis

One of the key strengths of a Unified Namespace is its ability to centralize and contextualize data from disparate systems. By integrating a data historian or time-series database with the UNS data, organizations can store extensive amounts of historical data in a structured and accessible way. This data becomes a powerful resource for analyzing trends, monitoring process performance, and supporting quality control initiatives. The implementation of Overall Equipment Efficiency (OEE) metrics in manufacturing can also be simplified using Unified Namespace by standardizing how machines report data, ensuring consistent and actionable insights. In practice, this is enabled by Production Monitoring with OEE, which provides a transparent, standardized view of equipment performance across lines and plants

With all data available in one place, teams can easily access and compare information from different production lines, shifts, or even sites. This enables more informed decision-making, helps identify opportunities for process optimization, and supports compliance with industry standards. Ultimately, historian data analysis within the UNS framework empowers organizations to move from reactive to proactive operations, reducing downtime and driving continuous improvement.

Looking ahead: potential for scalable rollout across the entire organization

The success of this project has sparked interest in other divisions of the corporate group. With Unified Namespace integration already in place, the same data can be shared across production sites, creating opportunities to extend the digital transformation journey.

Thanks to the advanced IoT architecture and intuitive software applications, the company now has a system that not only streamlines the flow of production data but also supports post-production reporting in a consistent and transparent way. By organizing diverse data sources within a single organizational structure, the foundation has been set for future innovation. The architecture also supports integration with data lakes for storing large volumes of structured and unstructured data, as well as data warehouses for fast, structured queries.

The combination of data modeling and one communication interface creates a blueprint for scalable growth. This blueprint opens the door to new opportunities—such as connecting AI tools and predictive systems that can analyze the data and automatically suggest process adjustments.

The unified namespace live environment continues to serve as the central hub for data management and operational insights across the entire enterprise.

Unlocking value through AI and Data Management

Benefits that can be gained from AI tools:

- Process and recipe optimization

Using AI to analyze current and historical setpoints, changes, and their effect on the process, it is possible to recommend improvements in the recipes in general, or even to the process parameters in real-time. It ensures higher stability and efficiency of the manufacturing environment.

- Predictive Maintenance

By applying advanced real-time analytics (AI/ML) to software and hardware solutions, the company can forecast equipment failures, schedule service proactively, and cut unplanned downtime.

- Smarter Operations

Embedding AI into the MES (manufacturing execution system) will provide real-time performance tracking, helping managers balance workloads and optimize production schedules.

- Efficient Collaboration

AI-driven assistants will streamline communication between sites, turning complex data into clear insights and speeding up cross-functional decision-making.

- Sustainable Growth

Using contextualized data within a framework of data standardization, AI can recommend process improvements that reduce energy use, lower waste, and support long-term profitability.

In this way, the project has laid the groundwork for further improvements across the enterprise, ensuring that digital transformation can evolve step by step toward smarter, more sustainable manufacturing.

Conclusion:

By adopting a Unified Namespace (UNS) and a modern IoT platform, the company has created a foundation where industrial data is no longer siloed but structured for business value. This ensures that teams across multiple sites can easily access the most relevant data, connect their industrial systems, and make informed decisions in real time.

According to a report by Mordor Intelligence, the digital transformation market in manufacturing will reach USD 440 billion by 2025 and grow to USD 847 billion by 2030, underlining the scale and urgency of investing in data integration. Similarly, a report by Integrate.io shows that organizations that successfully combine data from multiple sources and apply strong data governance practices achieve an average 354% ROI within three years, with business benefits worth nearly USD 19.5 million.

This project delivered tangible results, including:

- Improved operational consistency – recipes and production data flow automatically between central systems and local lines, reducing manual work.

- Greater flexibility – new recipes and adjustments can be deployed faster while maintaining full quality control.

- Transparent reporting – both real-time and historical data are available in one place, strengthening compliance and long-term insights.

- Readiness for AI – centralized data now supports predictive analytics, process optimization, and future automation initiatives.

As a result, the company has not only streamlined its daily operations but also built a scalable growth model—demonstrating how effective data management in digital manufacturing, including predictive maintenance, can translate into lasting competitive advantage.

Explore Transition Technologies PSC’s offer

Discover how we can combine your vision with our expertise in Digital Manufacturing, Unified Namespace (UNS), Industrial IoT, and Augmented Reality to accelerate your business growth.

By integrating IoT platforms with advanced production monitoring, Energy Advisor, and real-time data orchestration through UNS, we help manufacturers improve efficiency, sustainability, and decision-making. A Unified Namespace example like our recent implementation in the FMCG sector shows how centralized data architecture can unify recipes, production lines, and analytics into one seamless ecosystem.

Building on this foundation, our EcoPLM strategies and AI-driven analytics ensure that innovation continues seamlessly across the entire product lifecycle — from shop floor to enterprise level.