_Efficient Assisted Reality for business & employee development

Industry

Manufacturing, Industry

Challenge

- Reducing downtime

- Improving remote customer care

Technologies

AR

Results

- Remote support and maintenance in real time

- Digitization of after-sales services based on AR

OCME introduces digitization of service in cooperation with TT-PSC on technological innovations for providing real-time support with smart glasses and augmented reality (AR)

OCME – Moving Ideas

Established in 1954, OCME is a leading packaging machinery company headquartered in Parma, Italy and operating globally providing customers with premium, innovation-based solutions for packaging consumer goods. OCME does not consider themselves product vendors, but rather solution providers, anticipating trends through innovation. In fact, their R&D department has always been an essential component of their success with over 80 patents registered since the 70s, aiming to deliver cutting-edge answers to market’s biggest challenges, to meet demands affordably, sustainably and securely. OCME was present at Drinktec 2017 with their stand and presented their latest solutions, including the innovative app on Hololens glasses (augmented reality) to provide real-time remote support to their customers and digitisation of service.

Challenges and needs

OCME’s customer service has always been known for state-of-the art quality. OCME has been already providing their customers with a host of smart systems and services (such as the Contact Center and wearable devices) that use the latest technologies available to provide full instant support remotely and thus reduce downtime. However, as OCME wants to consistently push the envelope of after-sales support, their requested TTPSC to jointly develop a new generation of effective tools for delivering high-quality training platform and make it possible to support customers remotely in real-time, taking the problem directly from the service centres and providing the highest level of support anytime, anywhere.

Implemented solution – Advanced HMI on holographic training platform

New solution leverages augmented reality and envisages the use of Hololens glasses to transform the way OCME’s personnel can be trained and provide services to customers:

The solution offers following functionality:

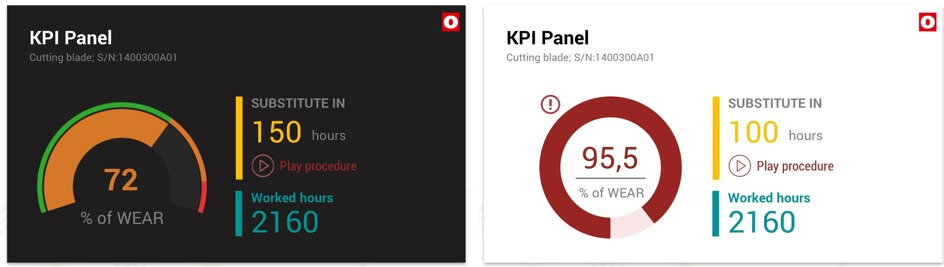

- Access machine and process KPIs

- Access procedure instructions in immersive, animated 3D environment

- Access machine documentation and instructional videos

- Hands-free experience with voice and gesture interaction

- Multi-user collaboration

- Recording holographic content overlaid on physical machines

Achieved result

Field technicians, operators and maintenance workforce will be guided into a convergence of digital/physical environments that allows to:

- view 3D video and animation regarding maintenance procedures and format setup operations for individual machine groups

- remote connection to the OCME Service Center

- access to instruction manuals, electrical diagrams and images

Augmented Reality allows to master technical knowledge quicker and better, becoming proficient in the jobs faster than even before. In addition, it allows to free the most skilled and experienced experts from the need of travelling around the world to handle service and maintenance by making them able to assist end-users remotely in real-time. The benefits from implementing AR solutions from Transition Technologies PSC are stacking every day, allowing OCME to strengthen their position as a global leader in packaging machinery provider. With OCME and Transition Technologies PSC, distance and complexity were no longer an issue. We are pleased to demonstrate a sneak-peak of further development focused on delivering real-time assistance on industry-grade head-mounted displays with even higher level of interactivity, glance-ability and hand-free experience.

Let’s get in touch

Contact us