_Right information for the right worker at the right place and at the right time

Duties performed by employees are inherently prone to errors. We are only human and our efficiency depends on a lot of factors. What if we told you that SkillWorx significantly improves the effects and quality of the work performed by your employees?

In most cases, errors or work efficiency below expectations result from time pressure, fatigue, lack of expertise, or an incomplete situational context. SkillWorx can help you change that.

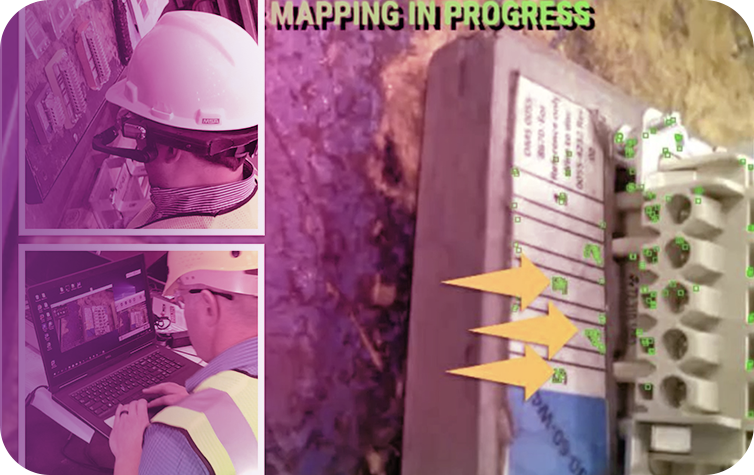

Our solution identifies the employee’s physical location and assigned tasks. Thanks to our proprietary technology – spatial intelligence, with which we have equipped the RealWear Navigator device – the employees can see what needs to be done, where to do it, and how to execute it.

Concise step sequences and quick, contextual, voice-activated, touchless access to technical information and data-searching allows the technician to concentrate on their task. This significantly improves the efficiency and quality of work of front-line employees. In addition, they are provided with information on how to document an inspection or other assignment carried out by them.

SkillWorx provides work instructions, production orders, checklists, pick lists, standard operational procedures, information on changeovers, changes in machine handling and other tasks in hands-free mode right in front of the employee’s eyes.

All in order to improve their safety at work, increase their productivity, speed up the induction of new staff, minimize formalities, and significantly reduce the risk of human error.

It is an excellent solution particularly in inspection-related professions (assurance, compliance, quality, regulatory, safety) where access may be difficult (hands-free, PPE required) and error tolerance is low (energy, EPC, manufacturing, oil and gas, resource extraction, transportation).

SkillWorx enables the implementation of bespoke, multi-dimensional inspections using AR technology and spatial intelligence, while minimising human error. The entire process can take place under remote expert supervision, making the inspection all the more effective.

Download a free SkillWorx report

Download_SkillWorx in numbers

Companies which have deployed SkillWorx solutions

40 %

business trips reduced

30 min.

changeover time shortened

80 %

faster induction of new employees

_Problems solved by SkillWorx

Production downtime, errors and ineffective paper documentation of tasks

Lack of up-to-date documents at the work station

Long induction of new employees

High costs of business trips of the employees

Lack of efficient warehousing logistics

Unavailability of experts at the time of a malfunction

_Capital Equipment OEM Support Platform

SkillWorx enables the infrastructure and implementation of the Capital Equipment OEM Support Platform – a platform that allows capital equipment manufacturers to enable their users:

- Feature overview

- Trainings (introduction, safety, operator, best-practice, advanced)

- Preventive maintenance work instructions (including a digital service and

- support log with potential for blockchain integration)

- Component status tracking

- Customer bulletins

- Product updates

_What our clients say about SkillWorx

Finally, we can allow technicians to focus 100% of their time to put value into our products. For a company like ours, a reduction in time spent on non-value-added tasks such as registration of parts or operation status is of huge importance and provides us with an extremely competitive edge.

Mark Jaxion

Senior Specialist Leading Industry 4.0 Strategy at Vestas

_Industries covered by SkillWorx

For SkillWorx, the sky is the limit!

_What our experts say about SkillWorx

Adam Gąsiorek

Chief Technology Officer

_SkillWorx components

Hardware

The core of SkillWorx is RealWear Navigator* – industrial wearable voice-activated computer.It is ideal for the industrial sector, where free hands are crucial for safety and efficiency. The device is a new generation tablet and offers 100% touch-free operation thanks to voice control. You can call up individual functions by voice using one of more than a dozen languages, including Polish. Thanks to its resistance to spills and drops from up to 2 metres, your employees can work and perform their duties freely in various conditions, increasing the quality of their work and their efficiency.

*SkillWorx is also compatible with RealWear HMT-1

See moreSoftware

How is SkillWorx powered? Through the PTC ThingWorx platform – an IoT platform designed specifically for industrial applications. Developed for comprehensive solutions with a full set of essential features. It enables integrating data both from countless purely software-based platforms (including MES, ERP, PLM, WMS, CMMS, CAQ) and other applications used to manage orders, warehouse, production or maintenance, as well as data obtained directly from automation devices, i.e.: sensors, PLC drivers or SCADA applications.

See more_SkillWorx solutions

_See how SkillWorx supports production in the wind energy industry

Vestas Wind Systems

Vestas Wind Systems A/Sis a Danish manufacturer, seller, installer, and service of wind turbines. It was founded in 1945, and as of 2013, it is the largest wind turbine company in the world. The company operates manufacturing plants in Denmark, Germany, India, Italy, Romania, the United Kingdom, Spain, Sweden,Norway, Australia…