_ecoPLM – a sustainable product development

_Embrace sustainability metrics first

80% of environmental impact can be determined in design phase.

50% of global green house gases are caused by extracting and processing primary raw materials.

30% of CO2 emission reduction is expected to come from the design stage

_Environmental aspects in design - a new paradigm

Sustainable product design is a pivotal KPI in the pursuit of product design for sustainability, with most parameters being established during the design stage.

Early assessment by stakeholders is crucial to preliminarily predict the outcomes of decisions made in the realm of sustainable product design.

Download the leaflet_Challenges

Predicting sustainability impact of the product.

Ensuring compliance with legal regulations.

Building a sustainable product development foundation.

_Unlock the power of sustainability in product development

Navigate product design with our sustainability Roadmap - Take 10 minutes to fill out our survey, and you'll receive an initial roadmap for navigating product design within 5 working days.

_Benefits

_Features

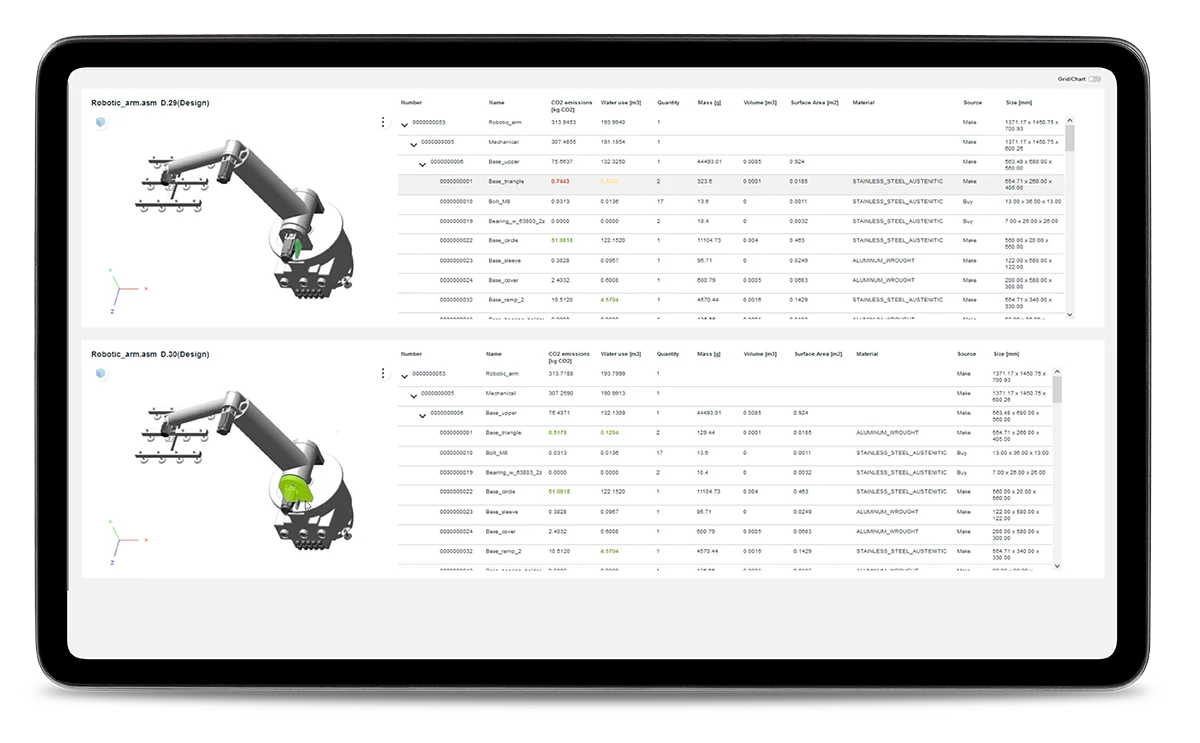

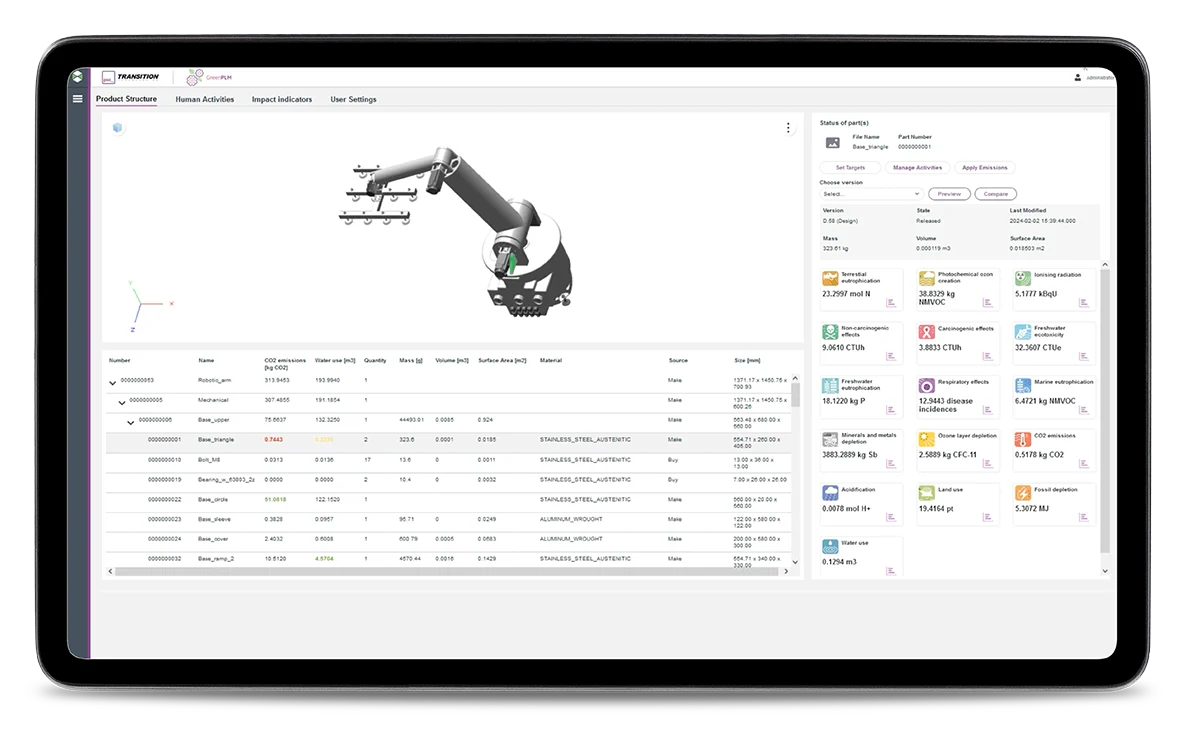

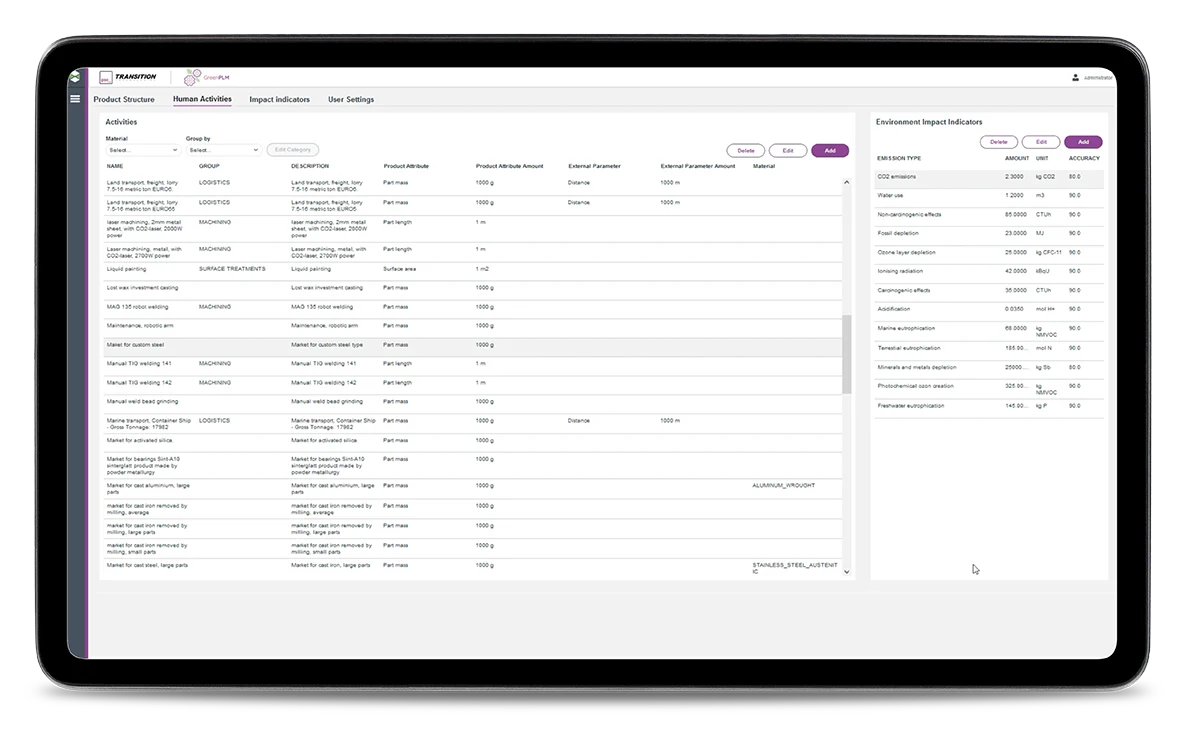

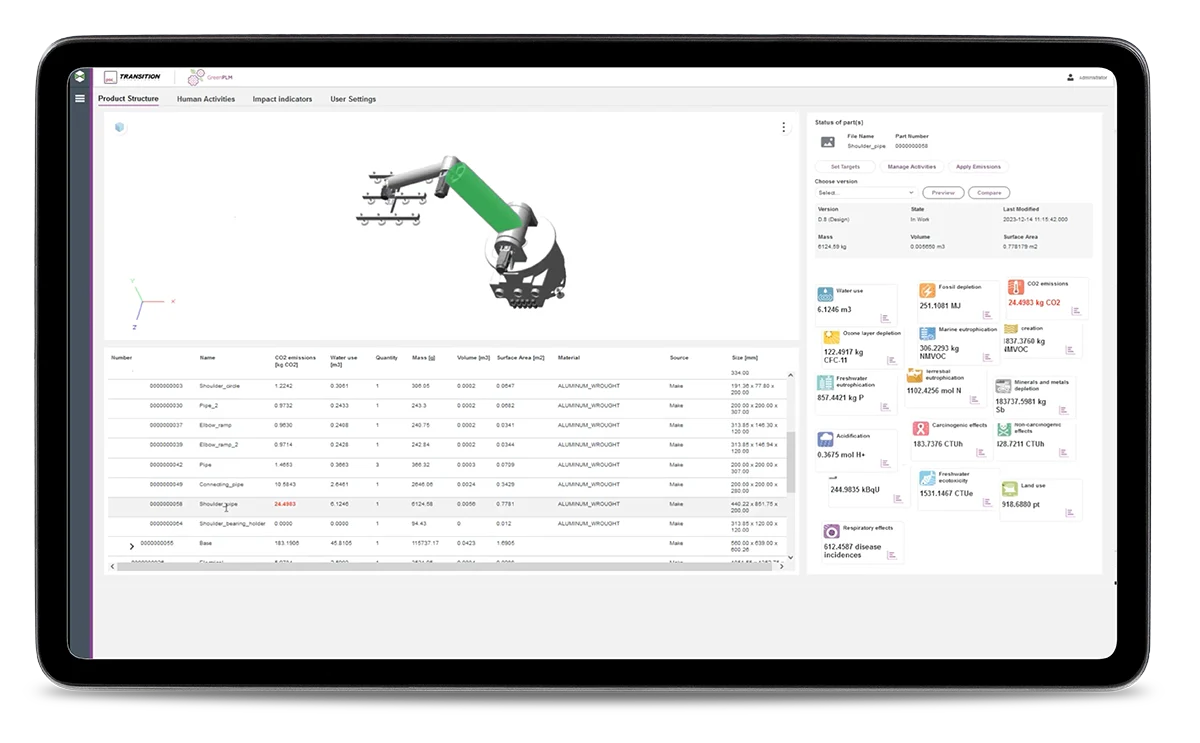

_Explore the capabilities of ecoPLM

_FAQ

Sustainability metrics are tools used to evaluate and accurately measure the environmental impacts, social, and economic durability of various processes. They are essential in helping organizations understand the impact and effectiveness of their sustainability initiatives and identify areas for improvement. These metrics can be applied to a wide range of sectors including manufacturing, agriculture, and even product development.

In the context of product development, sustainability and environmental metrics play a pivotal role. One such tool is ecoPLM, which provides a framework for assessing the sustainability of products throughout their lifecycle, from design to disposal. ecoPLM evaluates the environmental footprint of a product, including energy consumption, material use, waste generation, and other factors that affect the product's overall sustainability. The insights gained from this approach can then be used to inform sustainable product development practices.