_Augmented Reality from TT PSC supports the production processes of Vestas – the largest wind turbine company in the world

Industry

Wind Industry

Challenge

- Lack of tools to handle rapid job growth

- Updated paper documentation

- Long process of updating documentation

Technologies

AR, IoT, PLM

Results

- Optimize the implementation and training of new employees

- Flexible change of activities according to needs

- Effective sharing of knowledge and information

Vestas Wind Systems

Vestas Wind Systems A/Sis a Danish manufacturer, seller, installer, and service of wind turbines. It was founded in 1945, and as of 2013, it is the largest wind turbine company in the world. The company operates manufacturing plants in Denmark, Germany, India, Italy, Romania, the United Kingdom, Spain, Sweden,Norway, Australia, China, and the United States, and employs more than 21,000 people globally.

Connected Worker by Transition Technologies PSC

Adam Gąsiorek, CTO at Transition Technologies PSC: “I have the pleasure of working with Mark Jaxion, who is leading the IoT and Industry 4.0 strategy within Vestas VPS. I asked Mark to explain their strategy starting from the challenges and then going through the solution built together with TT PSC and ending with the impact made by Digital Thread on Vestas competitiveness.”

The changing workforce

Mark says: “In the next ten years over 30% of our workforce will retire. With many years of valuable experience and knowledge in the wind power industry, we are witnessing a dramatic change in the number of skilled blue collar workers.” Paper-based work instruction – copies kept in binders next to assembly lines cannot keep up with updates driven by increasing demand for product personalization and reconfigurable manufacturing.

Manufacturers have to support bi-directional knowledge capturing and sharing in order to enable a new generation of workers – connected workers – to complete job orders more effectively and with higher quality from day one.

Challenges and Needs

- Ramp-up cycles not supported with easy-to-use tools

- Book-binders not up-to-date

- Long process of updating instructions

- Time to consult the documentation is too long

Digital work instructions

According to Mark Jaxion: “This means technical work instructions available for end-users on-demand before they do work to ensure that they can perform the work in full or abridge it, if required. We focus on showing this information so the beginner can interact with it, dive down into the structures and discover information. Using the connection that we have directly to Apriso (MES), the parts that end users have in front of their eyes are contextualized – not overloaded information but only specific parts after the MRP run so that we can show visualizations with relevant parts.”

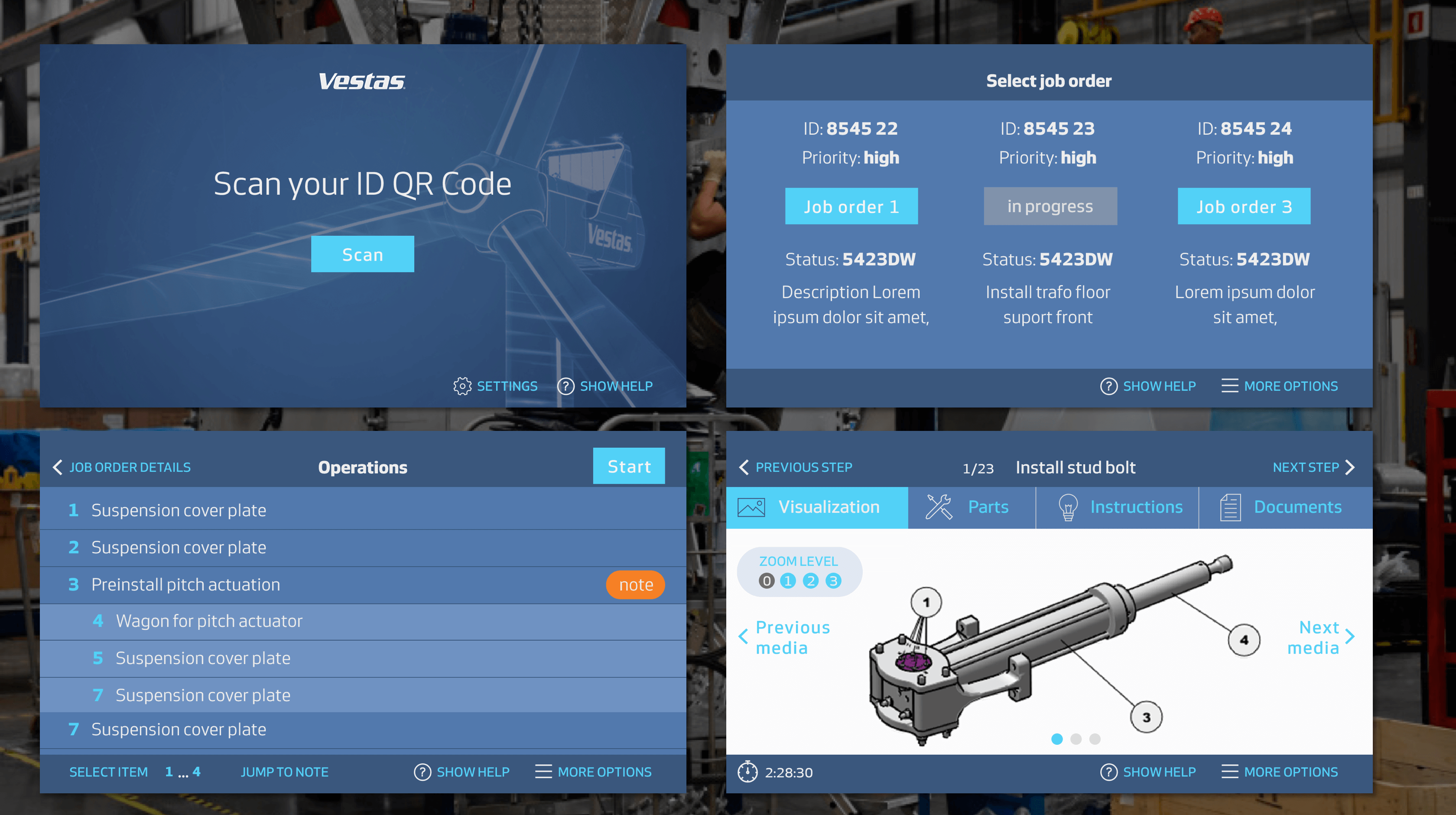

Applied solution – SkillWorx by TT PSC

The TT PSC team lead by Michał Neufeld – AR Solution Architect has delivered a hands-free experience for the RealWear HMT-1 headset. Our solution connects to the PTC ThingWorx Operator Advisor, detects and tracks the workers’ physical location together with what they are supposed to do there. We introduced spatial intelligence to HMT-1 in order to show which tasks, where and how should be done and to document what was actually done.

Achieved results – what benefits SkillWorx can bring?

We started the project with two goals in mind. First, to accelerate ramp-up cycles with east-to-use tools. This will shorten the time needed to onboard new personnel and track their performance. They can be trained much faster in terms of processes, tools, materials, and workstations. Second, to facilitate the flow of information by providing both contextual information and knowledge capture in the form of voice memos, photos, and videos. This tribal knowledge can then be reviewed, shared, and archived even during a shift change. Both goals contribute significantly to solving the challenges of a changing workforce and a worker skill gap.

How it works

On the RealWear HMT-1 headset, employees have a list of job orders that come from Apriso. When workers dive into a particular order, they receive information about its status along with environmental data. The process plan is contextualized and includes only those operations that are assigned to the worker and the workstation where the job is to be performed. Every operation is described with following items: a text description, a list of relevant parts and visualizations which can be composed of pdf files, 2D images, Creo View 3D files and videos. The description can be read out loud by the headset in cases where the technician has low visibility. The users can zoom in to the level of fidelity that is relevant for them to execute the order.

Benefits

- Accelerate onboarding

- Train operators before prototype assembly

- Bi-directional knowledge capturing and sharing

- Lower time required to access information

- Trigger change request on demand

Why hands-free?

If you ask Mark why a hands-free experience is so important, he will tell you: “In the blades area, the workers cannot use their hands for navigating through the data they need. Their hands are often sticky, they work with resin and carbon-fiber. There are also use-cases on a shop floor where people are basically sitting on their back the whole time while working with torque wrenches in a yaw system.”

Because of this we have to enable them to have their hands free and provide them with instructions in a form that is easily navigable under such working conditions.

Impact of Digital Thread

We empower frontline workers through connecting multiple systems like PLM, MES, ERP, IoT and providing hands-free access to digital work instructions. The backbone of this hands-free solution is built on the same data source as the ThingWorx operator Advisor. This ensures that when a change is made through the Change Management System, the information is replicated in real-time. This data is then delivered to the headset (and/or tablet). Regardless of where the work is started or finished, everyone can see the same Digital Thread, the same information at the right time and at the right place.

Mark says: “For the first time the technology is getting out of the way. Finally, we can allow technicians to focus 100% of their time to put value into our products. For a company like ours, a reduction in time spent on non-value-added tasks such as registration of parts or operation status is of huge importance and provides us with an extremely competitive edge.”