_Augmented Reality in automotive industry on Asian market – Transition Technologies PSC

Industry

Automotive

Challenge

- Improving information flow

- Digitization

- Shortening quality control time

Technologies

AR, IoT

Results

- Pilot Testing of AR Solution

- Implementation of AR solutions in production facilities

- Improving the efficiency of information flow

Hirotec Corporation Japan

HIROTEC Corporation designs, develops, and manufactures automobile closures, exhaust systems, automotive production tooling, and stamping dies. Founded in 1958, HIROTEC’s global team of over 5,000, provides world class products and solutions to the automotive industry from over 30 facilities. Its main customers include Mazda, General Motors, and Fiat Chrysler Automobiles.

Challenges and Needs

HIROTEC has very strong quality and inspection procedures in place to guarantee its customers receive 100% defect free products. However, these procedures are currently paper based, and require a lot of manual reporting. Everything was well documented and well described in excel spreadsheets and printed for each inspection session. The current procedures require HIROTEC team members to consult standardized document to guide their testing activities. As they perform these steps, they must pause their work to document the results of their activities, check the document for the next step, and then execute the test. These paper based reports must then be collected and typed into digital tracking systems. This can lead to lag in information throughout the organization. Also, this process leads to heavy levels of human work to collect and store the data.

HIROTEC is looking to identify and test solutions driven by the digital transformation to aid in revolutionizing their current procedures. HIROTEC also wants to test and identify solutions which can help accelerate their velocity of information throughout the organization.

Applied solution

HIROTEC wanted to begin piloting a kind of platform/system where:

- Quality inspectors can perform inspection session having instant access to procedure step information and their both hands free for following instructions

- Inspector’s work is instantly stored in system and they don’t have to write down results on paper

- Management level employee can benefit from having instant access to digital inspection session results.

Here Vuforia Studio came as a way to create procedure flow step-by-step and Realwear HMT-1 as an end interface solution for inspectors. This approach was also backed up with Thingworx as a storage platform.

At workshop, it appeared that a few procedures (not only door inspection, but also equipment inspection, workplace inspection at the beginning and end of shift etc.) have steps that fit more or less the same structure. Each step has a clearly defined title, standard to comply and checking method. Optionally each step can have up to two pictures to identify inspected elements better. We decided to take an extra step and use Vuforia Studio not only to implement static views, one view per each step in procedure, but to develop a kind of framework for viewing structured steps. All the process and step definition information is stored in Thingworx.

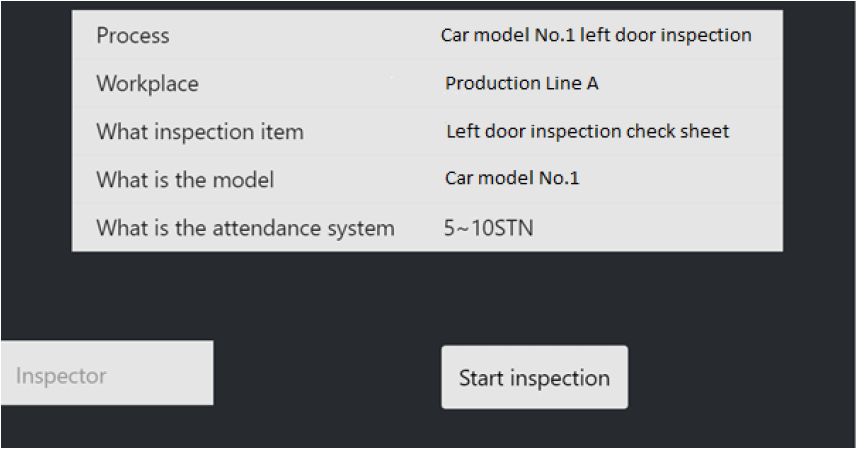

First, an inspector has to scan a Thingmark which corresponds to inspection process. Then, some basic information about process appears and inspector has to provide its number to start:

When the inspector starts, this data (who, when, what process) is stored in Thingworx and information about process step definition is retrieved to display next screens:

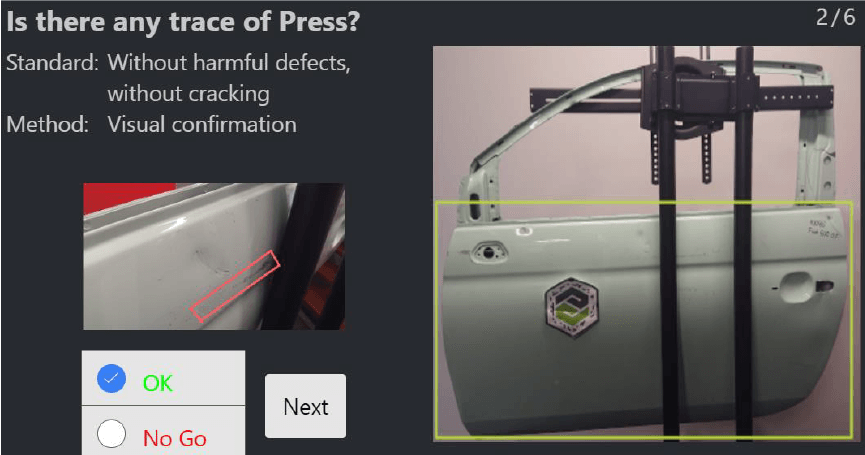

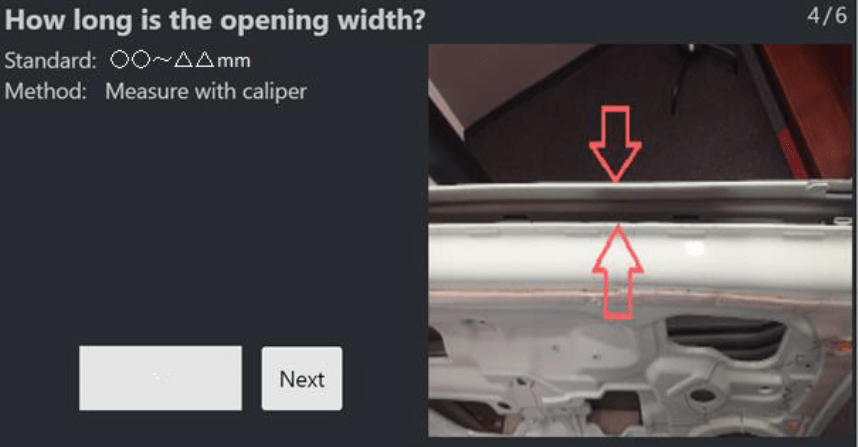

Each step definition has a template attribute in Thingworx which can be:

- information – just displaying some basic info and “Next” button

- ok/ng – displaying a radio button “OK” or “No Go” and “Next” button when any radio is selected

- exact value – displays an input filed for inspector to dictate a value, such value is then compared to step definition value

- value-in-range – displays an input filed for inspector to dictate a value, such value is then compared to step definition value range

For the last two cases, the experience decides if a step result is either “OK” or “No Go” based on a calculation.

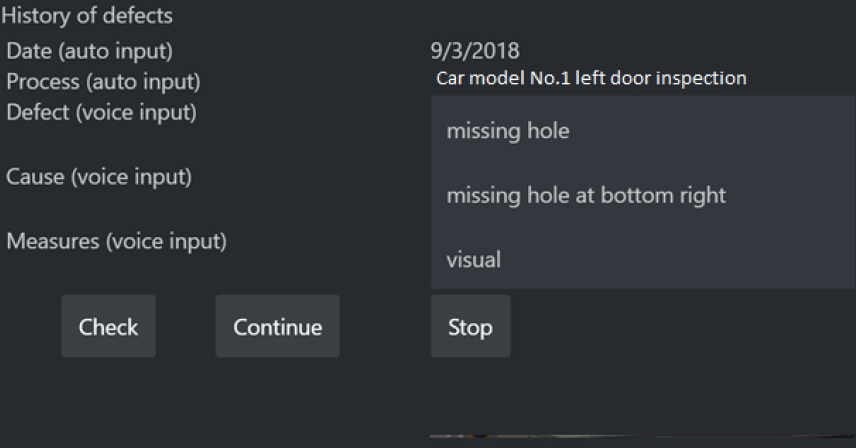

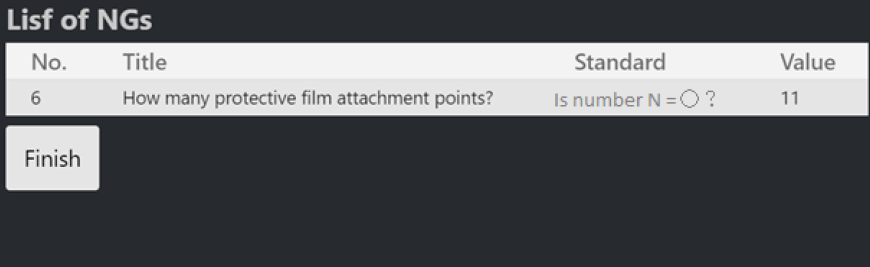

In case of “No Go” there is additional screen for providing more defect information:

When the whole process is finished, there is summary screen displayed for inspector information:

If needed, an inspector can retrieve more information on failed steps:

Note: UI screens have been simplified for this article and all sensitive HIROTEC data was removed.

All information about process steps execution is stored in Thingworx:

Thanks to structured processes and using such a framework, introducing new process appeared to be very quick and easy.

Achieved results

By pilot testing an innovative and easy to use augmented reality-based solution from Transition Technologies and PTC, HIROTEC was able to better understand the merits of deploying Augmented Reality based solutions throughout its manufacturing facilities.

HIROTEC was able to identify a new way forward which will enable for faster reporting activities which also increase the velocity of information throughout their organization.

Utilizing lessons learned from this pilot testing, and the framework created by Transition Technologies, HIROTEC is working with cross functional teams with stakeholders from across its organization to identify opportunities to deploy this solution at scale across its global organization to improve the quality of specialists’ work.

Looking at the implementation from the perspective of a person who is responsible for employee’s work, it can be easily said that using AR technology allows for a better analysis of specialists’ work and activities performed by them.

If you are wondering how AR technology can influence your company, contact us!

Let’s get in touch

Contact us