_Azure cost optimization for welding industry leader

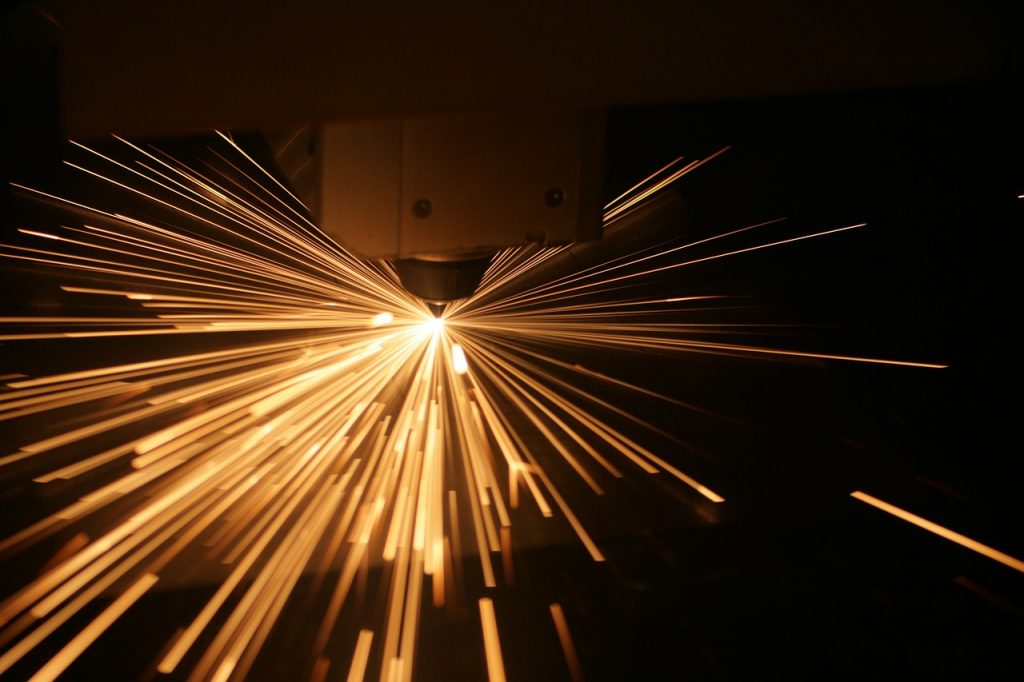

Industry

Manufacturing, Welding and Metal Cutting

Challenge

- Improving analysis

- Improve welding productivity and quality

- Optimize cloud costs and data access

Technologies

IoT, Cloud, Microsoft Azure

Results

- High data availability of 99.99%

- Reduction of subscription costs by up to 50%

- Real-time data upload and analysis

About ESAB

The ESAB Group (Elektriska Svetsnings-Aktiebolaget) is a world leader in the production of welding and cutting equipment and consumables. Owned by Colfax Corporation ESAB was founded over 110 years ago. Although originally from Sweden, it currently covers regions of Europe, North America, South America, Asia / Pacific, and India.

ESAB’s offer includes innovative and world-renowned devices and solutions developed together with their customers. They are constructed based on the knowledge and heritage of the global leader in the manufacturing industry.

Challenges and Needs

ESAB is a leader and forerunner in implementing new, innovative, and novel digital solutions for its base customers, aiming to disrupt the welding and cutting industries. One of these solutions is an online IoT software platform, providing easy to use tools to analyze and improve welding productivity, quality, and efficiency. It provides control over the work carried out, thoroughly gathering and analyzing big data from a fleet of power sources and welders’ operations at the manufacturing floor.

When creating the architecture for the platform, we had to pay attention to the strictly defined requirements of the client. Needs related to the necessary computing power and security had to be considered. Moreover, we had to provide space for data storage and the ability to send it in real-time. Finally, extensive analytics of the collected information should have been taken into account.

The optimal step that allowed to solve potential problems with performance, high availability, data security, and compliance with all requirements specified by ESAB turned out to be the choice of public cloud provided by Microsoft. Due to the fact that the platform is based on real-time information analysis, the key condition was the high availability of telemetry data collected from devices from around the world (IoT paradigm).

To effectively carry out the concept of integration at the level of industry 4.0, the choice fell on the Azure IoT Hub with supportive Azure solutions like NoSQL Database CosmosDB and Stream Analytics. Appropriate data modeling and their contextualization was performed on it to be able to logically link all information flowing from devices and machines to their digital equivalent.

Due to this, not only information but also additional functions can be performed in the context of a given device, keeping in mind its specificity. Examples include remote software update and device management.

Certainly, having data, the next required stage is their visualization using the IoT Platform for the needs of end-users, creating appropriate access screens, providing necessary functions, and displaying data in real-time and historical reports.

The key element binding all these functions described above is the separation of data and access levels – not only between different organizations but the roles of user data as well.

The right execution of this complex project gave enormous development opportunities, and proper configuration of services enables to build a competitive advantage and provide business value.

Applied solutions

To make sure that the system will work properly, we have used the virtually unlimited possibilities of Azure public cloud. The right combination of a wide range of services allowed us to create an ecosystem that met the client’s requirements.

The app has been designed as a global solution. ESAB has clients around the world and the data they collect comes from welding machines located in different regions of the world. Microsoft Azure has built-in, ready-to-use IoT solutions. When creating the platform, we used the scalable Cosmos DB global database, which receives, via Stream Analytics, telemetry data downloaded by Azure IoT Hub.

The ability to send data in real-time was ensured by using the Azure IoT hub service. It registered all welding information and system status sent simultaneously by many devices.

Telemetry data used in “IoT” are sent as large data packets, to which appropriate space must be provided. They are backed up and processed with ready-to-use global distribution and explicit multilayer replication. The Azure Cosmos DB database service is responsible for high availability at 99.99% and five properly defined consistency levels. Simply put, we used a service that not only provided enough space but also the certainty that the saved data won’t be lost.

Data analysis has been provided by the Azure Stream Analytics website which enables a complete stream of data processing using algorithms based on Machine learning and provided in the Pay As You Go, model, for example, fees are charged only for the real consumption of the website resources. By means of data flow (in architecture so-called “warm path”) in real-time starting from downloading data from the so-called “Input” from IoT Hub to “output” – Cosmos DB. These are just some of the services that were used to build a highly advanced environment that created the platform.

However, the finished product wasn’t the end of work for Transition Technologies PSC. The high performance of the infrastructure approved for use by clients resulted in high fees for virtual machines, database services or access points. Therefore, we had to find a solution that would allow us to optimize expenses while maintaining key functionalities for the client.

The challenge for our team was to maintain the advanced cloud environment at the appropriate financial level. The key was to balance the efficiency and use of resources. After the stages of planning, building, testing, and implementing the entire infrastructure came the stage of monitoring the costs generated by Azure services.

The key to optimizing the costs generated by a very large number of services was close cooperation with the programming team and a full understanding of the principles related to setting performance for individual elements.

The above approach is one of the most important aspects, enabling the optimization of infrastructure maintenance costs in the cloud. The real challenge was to maintain high performance without involving large funds.

We started the optimization process with a detailed cost analysis. The main and crucial tool designed for this purpose is the Azure Cost Management service – it helps to monitor expenses for individual services, track the use of resources thanks to one consistent view, and gives access to fully operational and financial data.

In the Azure Cost Management service, we used:

- Cost Analysis – real-time cost analysis

- Monitor Budgets – creating our own budget for a given group of services or a given subscription, due to which we have full control over expenses for, for instance, a given project

- Information about events through which we will receive notifications in the form of e-mails, text messages or notifications on various messengers.

Another key tool to help reduce all unnecessary expenses was the Azure Advisor service. As part of its capabilities, we used the recommendations regarding:

- High availability – ensuring and improving business continuity of major business applications.

- Security, which allowed detecting threats and vulnerabilities in our infrastructure.

- Performance to improve the speed of our applications.

- Optimizing costs and reducing overall expenses for Azure.

Through Azure Advisor we were able to get proactive, practical and personalized using the best practices.

In the solutions provided in the PaaS model, the fee depends on the length of time the service is used and the number of, for example, Azure Stream Analytics units, the amount of data transfer in the case of data storage such as “Storage Account” or the number of messages sent in the case of “Azure IoT Hub”.

Results

A thorough understanding of the requirements of the platform, detailed data analysis, optimization of expenses, and increased security of our client are the greatest successes in the implementation of this project. Through our team’s actions, we’ve been able to increase application speed and reduce subscription expenses by up to 50%.

The project’s success would not have been possible without close cooperation between many different enterprises. Transition Technologies PSC was a part of a team that also included ESAB, Microsoft, and other third-party companies.

Thanks to the abovementioned effects, ESAB achieved significant savings and is even more convinced to the effectiveness of cloud solutions.

Let’s get in touch

Contact us