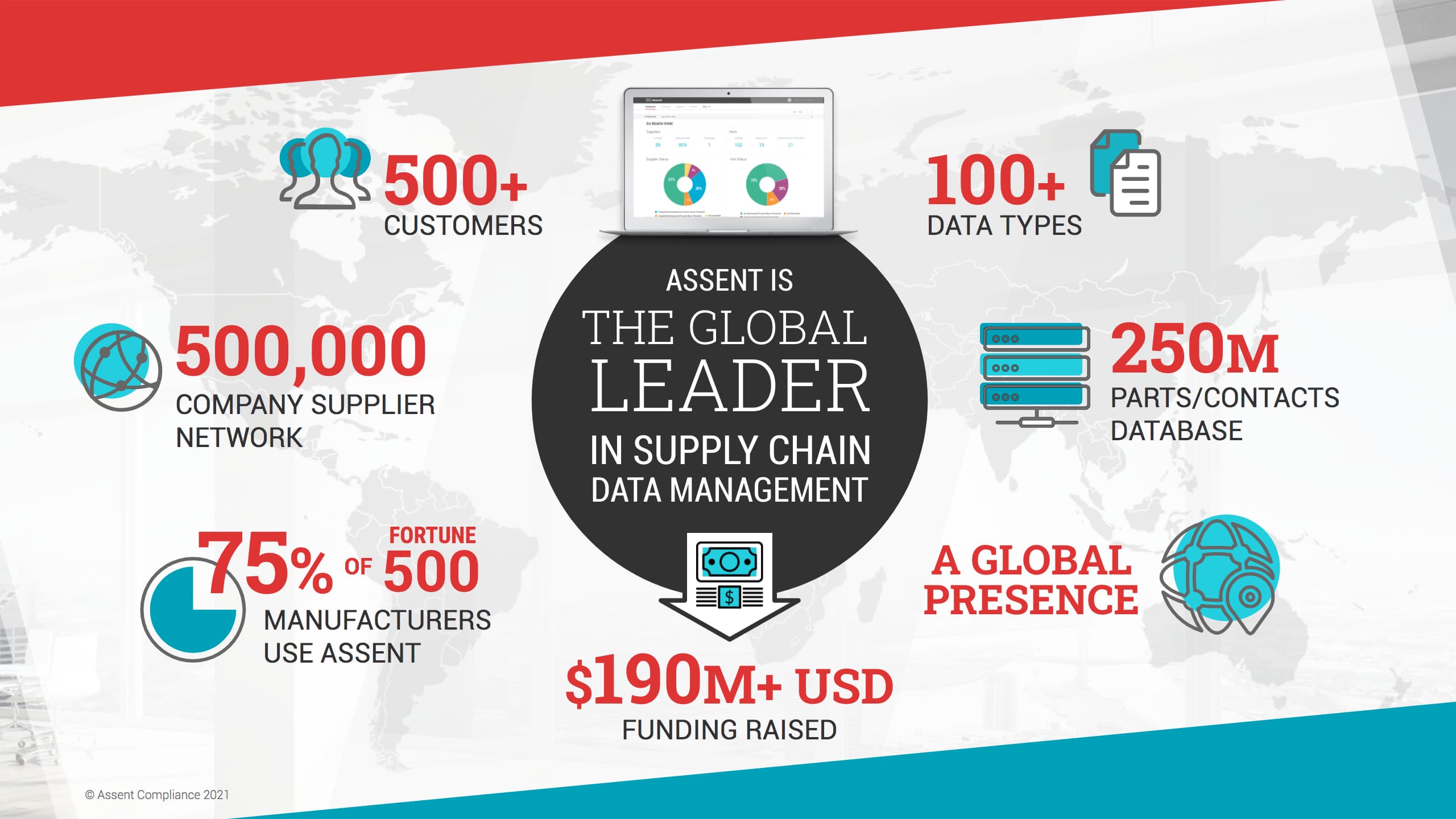

About Assent Compliance

Assent Compliance is a global leader in supply chain data management. They enable companies to better understand their supply chains through data transparency and traceability, allowing them to protect their brands, remove market access barriers, and reduce operational and financial risk. The Assent Compliance Platform is their comprehensive, centralized solution that helps companies meet their legal and contractual product compliance, vendor management, and corporate social responsibility requirements. It automates data collection and management, providing detailed reporting capabilities for regulations such as the European Union (EU) Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) Regulation, EU Restriction of Hazardous Substances (RoHS) Directive, the California Safe Drinking Water and Toxic Enforcement Act of 1986 (Proposition 65), along with many others. Assent’s software updates alongside ever-changing regulations, allowing companies to always remain ahead of their chemical reporting requirements.

Background

It is vital that product lifecycle management (PLM) systems provide product engineering access to product compliance data throughout a product’s lifecycle, so they can make relevant choices and search for supplier parts that meet all the regulatory requirements for which they are in scope. However, Windchill, a PLM system developed by PTC, is not capable of managing or assessing environmental compliance data independently.

That is why PTC and Assent Compliance partnered to create Windchill Product Analytics in 2018. As a result of this partnership, the Assent Compliance Platform is designed to be the preferred product compliance solution for Windchill customers.

To make this partnership a reality, PTC recommended that Assent use Transition Technologies PSC as their preferred Windchill System Integrator and solution partner, as they offer established experience in building interfaces between Windchill and other systems.

Objectives & Primary Assumptions

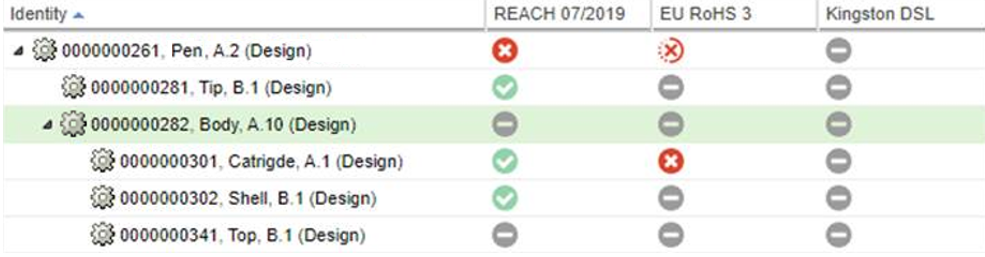

The principal objective of building the integration between Windchill and the Assent Compliance Platform was to provide access to compliance data housed in the Assent Compliance Platform to product engineers working in Windchill, in a similar manner as Windchill Product Analytics (WPA). Windchill would feed required product data — including both company (regular) parts, supplier parts, and part structures — into the Assent Compliance Platform, and share information about suppliers and supplier contacts (if created in Windchill). The Assent Compliance Platform would then calculate environmental compliance status for a predefined list of standards such as the EU RoHS Directive, EU REACH Regulation, and Proposition 65, and share that information with Windchill.

Users would also be able to navigate to the Assent Compliance Platform by clicking a compliance status icon to view compliance details for a specific part. The integration would also guarantee compliance regulation standards lists, such as those under the REACH Regulation, RoHS Directive, and Proposition 65, are kept up to date as they evolve during the product lifecycle. The integration would support both made- and bought-sourced parts. The latter would also have associated supplier parts coming from different suppliers when the Supplier Management Module is used in Windchill.

Challenges

PTC Windchill and the Assent Compliance Platform were designed to serve different purposes, meaning their approaches to defining data models are significantly different. Windchill defines product structure in a flexible, complex format compared to other, non-PLM platforms. For example, Windchill identifies two types of parts: regular parts, often referred to as company parts, and supplier parts. Many different objects can be linked to many other objects. In the Assent Compliance Platform, both supplier and company parts are originally different attributes of the same object, making integration challenging as it was necessary to evaluate risk mitigation steps that accounted for these differences.

Synchronizing the compliance status of entire bills of material (BOMs) was another significant challenge. A simple change in the product structure — such as adding or removing a leaf part — could potentially result in a change of compliance status for every parent part upstream in the structure, forcing the recalculation of compliance statuses for all parts in a BOM. This had the potential to cause issues, especially when trying to implement compliance recalculation as part of check-in post-processing in Windchill, so it had to be addressed to maintain performance.

Approaching the Solution

A small concept study was executed to validate select approaches for implementing the solution, resulting in a decision to build the integration as a Windchill extension. The main advantages of this approach included:

- Direct access to Windchill events: Data from Windchill is communicated to the Assent Compliance Platform immediately after changes are

- Access to Windchill features: The Assent Compliance Platform was given access to features and components such as the Windchill queues and database without the need for third-party software.

- Infrastructure simplicity: Installation of the Assent Compliance Platform as a Windchill component on the same server as Windchill.

The resulting solution was named the ACI Connector. It enables the publication of the following objects from Windchill to the Assent Compliance Platform:

- BOM.

- Regular/company parts.

- Suppliers.

- Supplier contacts.

- Supplier parts.

The solution also supports the ability to receive information about compliance status per regulation.

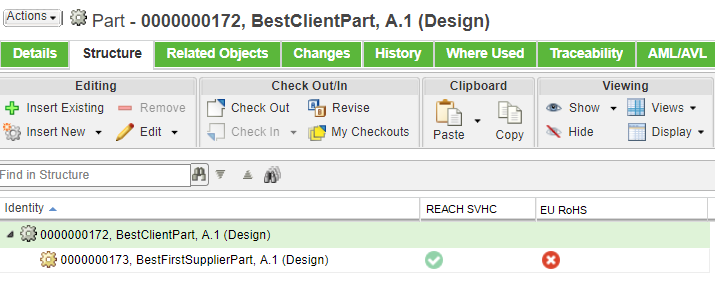

Windchill receives the compliance status of each part under each regulation from the Assent Compliance Platform. The list of available regulations is configurable, allowing customers to add or remove regulations as their needs evolve. The ACI Connector supports publishing single client and supplier parts, as well as entire BOM structures. The Assent Compliance Platform then produces a roll up of product compliance from supplier parts, to associated client parts, and upstream product structure.

The Assent Compliance Platform immediately receives information about structure elements and any structure changes, such as part check-in, part revision, and the addition or removal of a supplier part. This signals the Assent Compliance Platform to recalculate compliance statuses for relevant sections of the BOM. To do this, the Assent Compliance Platform identifies which parts of the structure require compliance status updates and relays that information back to Windchill. The status is then displayed in the relevant assembly, allowing the customer to make more informed decisions on product design as it pertains to compliance.

The Assent Compliance Platform efficiently produces product compliance status roll ups, and the ACI Connector ensures necessary product data is delivered to the Assent Compliance Platform on time, allowing customers to receive the recalculated compliance status almost immediately after updating part data. Because of this seamless connection that PTC named Assent as its preferred compliance solution to work with Windchill.

The ACI Connector has many additional features, including its support for revision-specific part compliance. This feature allows the tracking of compliance status for each revision of a part. The ACI Connector also features support for made parts (i.e. parts made by the company itself) as well as bought-sourced parts (i.e. parts with an associated supplier part or parts that may be provided by multiple suppliers). Finally, the ACI Connector supports installations with or without Windchill’s Supplier Management Module, enabling the management of suppliers and supplier parts within Windchill.

Integration Reliability: Going the Extra Mile

The ACI Connector is a robust integration solution that uses a RESTful Application Programming Interface (API) to seamlessly connect and communicate between Windchill and the Assent Compliance Platform. This connection is always initiated by the Windchill system, and outbound transfer of product and supplier data starts the moment an object is created or modified. The Windchill system routinely pings the Assent Compliance Platform for updated compliance data, which is then stored in Windchill’s database to ensure availability to Windchill users. Communication between Windchill and the Assent Compliance Platform is fully asynchronous through the use of Windchill queues, making these systems loosely coupled, and errors are dispatched to a retry queue in case of an exceptional scenario. This retry mechanism guarantees appropriate order of operations.

Beyond Technicalities

Although the more technical aspects of building integrations can be challenging, the less technical pieces also play a significant role in the success of the project. When ignored, these pieces lead to project failure. These kinds of projects also involve people with different backgrounds across departments or companies coming together, presenting their own issues regarding communication and synchronization.

The ACI Connector project showed many best practices in organizational and governance areas and was highly visible across both organizations. From the very beginning, both the Assent and TT teams demonstrated high levels of commitment to this initiative. Stakeholders were dedicated to maintaining transparency and building a speed of trust practice, resulting in exceptional performance from both teams.

There are often many constraints when integrating enterprise platforms, but Assent showed a lot of openness in adopting their system to the needs of the integration. If a concept needed to be implemented in the Assent Compliance Platform, the team at Assent put the work in to make those changes rather than creating workarounds. As a result, the integration between the two platforms was a great success.

TT PSC knows PTC Windchill inside and out. Their extensive knowledge of this highly configurable product has been instrumental in our ability to integrate. By relying on TT PSC’s knowledge and experience, we have dramatically increased our development speed and made this challenging integration a reality. As individuals, TT PSC are kind, professional, and great to work with. Thanks TT PSC!