Nobody would be surprised by the statement that the Automotive industry is innovative in its nature. Cars are machines that historically revolutionized many areas of industry themselves, and today we can’t help but notice that the industry has not slowed down even for a moment and has always been focused on technological growth that serves both the business and its customers.

Providing comfort and safety is definitely not enough for modern car users. Today, it is expected that the driver will be always provided with information on both the car(engine, tire pressure, fuel usage, range) and the outside (traffic, weather, optimal route). Moreover, information displayed to the driver is often not as trivial as a parameter value read from a gauge, but a result of a specific algorithm that processes the data. Not to mention the needs of our passengers…

Automotive industry is no longer perceived as conventional. Internet of Things and the digital transformation which it caused definitely contributed to that. That statement can be validated by a report provided by the Gartner company. According to that report, the Automotive Industry supported by IoT is beyond anyone’s expectations. Business and its customers expect cars to become mobile smartphones which, using IoT, will be able to communicate with other systems, applications and devices as well as with each other. The impact of IoT on the industry has been proven just by the fact that by the end of 2020 more than 250 million cars are to have advanced connectivity functions.

Automotive Branch is aware of that potential!

That is why, according to the Gartner’s report, by the end of 2020, IoT solution suppliers are to generate 300 million $ of revenue and the IoT market in Automotive Industry alone will grow over 7 billion $.

IoT supported areas in automotive industry

Automotive industry is facing an enormous challenge to meet the expectations of its customers and the market. New technologies are making it easier to fight the competition, and IoT is helping to implement those, supporting continuous development and addressing the needs of the branch perfectly. Looking closer at the automotive industry and IoTs’ possibilities, it is easy to identify areas that are key for the producers and in which new technologies have a role to play.

Market is expecting smart, connected cars that will gather, analyze and report data. These tasks are considered fundamental for Internet of Things. Let us take a closer look at some of the areas that can benefit from IoT solutions.

Product Lifecycle Management

Are you aware of the fact that IoT is accelerating the engineering roadmaps and can lead to even more effective product lifecycle management? In many companies the process of implementing changes is a very complex task that may cause delays in earlier stages of product development and at the same time delay introduction of the product to the market. In the world where brands must react quickly to the competition and consumer needs, it is crucial to accelerate engineering processes. In addition, it is important that engineers contribute to the cost reduction of a final product in the earlier stages of product development. They can do that thanks to the data analysis and tools responsible for monitoring product efficiency (or its elements) as well as historical data processing.

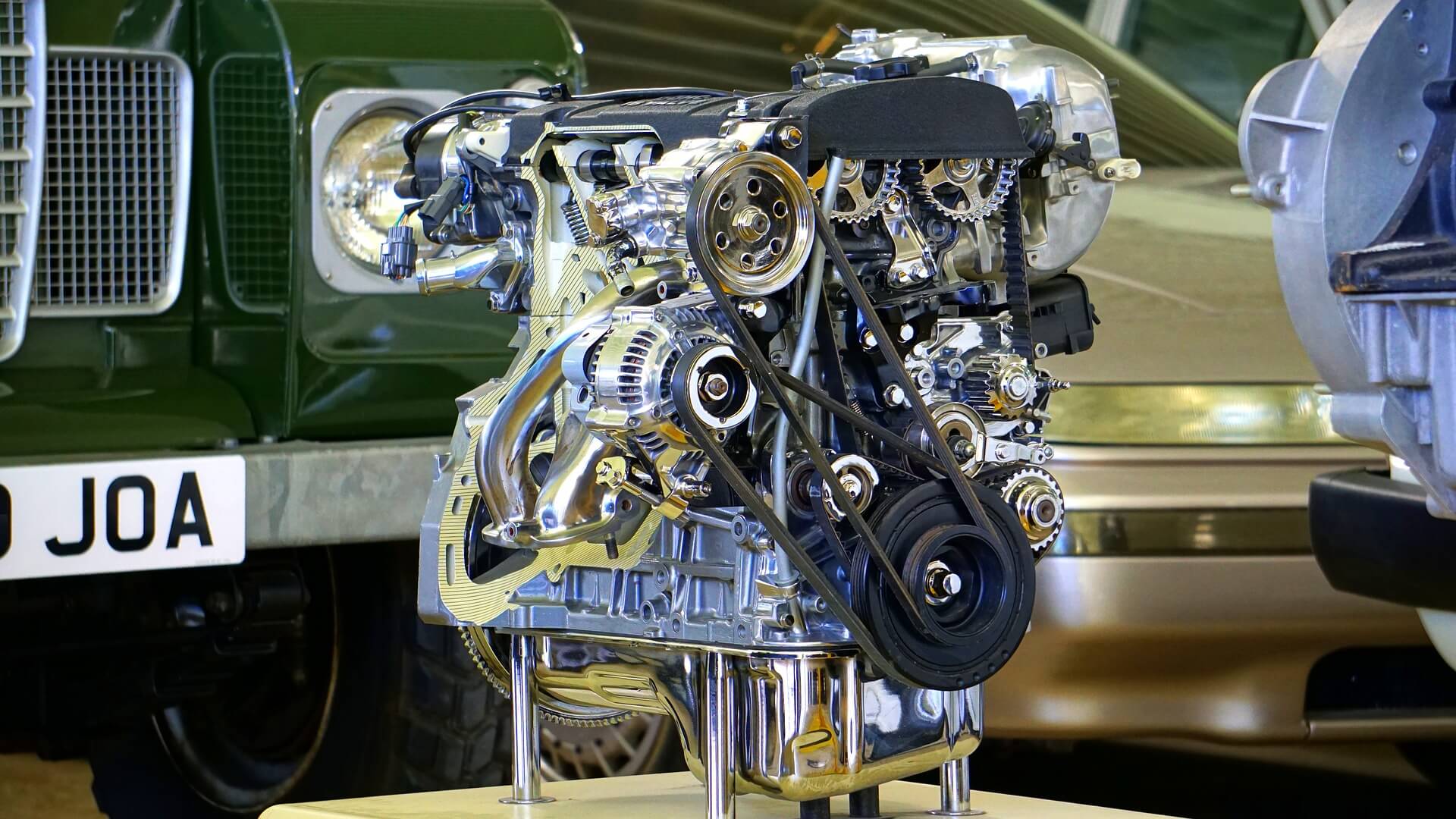

Automotive industry consists of a multitude of segments which are divided further into more specialized divisions. Similarly, the number of elements that are required to build a car is enormous and what comes with that is the amount of information that is being gathered throughout the whole lifecycle. Data storage and access problems can be solved with the use of new technologies. Those can also help with efficient prioritization of tasks and improvements for specific parts. All that to maximize efficiency and gain a competitive edge.

Production Process Optimization

Car manufacturers are constantly looking for ways to improve processes in their factories. Control, planning, machine uptime monitoring and managing resources are only some of the issues that can be addressed by IoT. The amount of processes, activities, work and information that can be gathered in a single factory is quite large, and what if there are more of them scattered across the globe?

Properly defined problems and solutions, defined by IoT architects, can help in optimization of efforts that have a real effect on the production costs. Managing the service jobs and maintenance as well as minimization of the production lines downtime are some additional examples of the tasks that IoT can provide solutions for. The results of the implementation of such solutions can be observed not only in the improvement of people’s and machines’ work efficiency, but also its quality.

Design/Prototyping

It’s quite obvious that in many cases the visual aspect is the most important one that people consider while buying a new car. This causes car companies to put more emphasis on the design and prototyping stages. The influx of augmented and virtual reality solutions has already had a big impact on those, and the number of use cases is increasing every day.

Replacing physical car prototypes with virtual ones is one of the ways to reduce costs that car manufacturers implement. IoT solutions can not only support the production of a virtual prototype but also help the process, its participants and communication.

Augmented reality at car dealerships? It’s pretty common. Tablets and other devices armed with AR/VR apps allow you to see your dream car in the exact configuration that you need, during your first meeting with a dealer. In addition, presentation of the solutions and components that haven’t reached production yet might not be as distant as it sounds.

System Integrations

IoT provides various frameworks that can be used to integrate systems already existing in infrastructures of firms and corporations. Using them, communication between a production line, back office and accounting is not a complex problem. Production line data aggregation and sending it to other systems, where it can be processed and displayed in a form of a simple report that is easy to understand for a specific group of users, are some of the usual tasks of Internet of Things.

A concept that is particularly close to the integration topics is “Application Hub” in which the IoT platform has a central role in the application’s infrastructure. In that architecture model, the platform is used to control the data flow between the sources(production lines, hardware, devices, databases, file systems), and recipients(management and control systems, displays, end users). This solution is getting more and more interest among car manufacturers that are always looking to gain more control and easier access to information.

Autonomous vehicles

The autonomous vehicles have been developed by different companies around the world for years. However, the realization of that concept is not possible without the intelligent infrastructure, which will make autonomous driving smooth and safe. Cities need to enhance their infrastructure by lane markers and electronic road signs. Thanks to the IoT solutions, such things as turn signals or mirrors might turn obsolete, and even without them, new technologies will be able to provide comfort and safety to the passengers, and not only.

In addition, by gathering data from sensors around the city and cars, it will be easier to identify the weak points in infrastructure and find appropriate solutions to address them.

Predictive maintenance

Considering the number of elements that make up a car, it is natural that the level of utilisation of particular parts will be different. By collecting data on the parts usage and problems/failures occurring, we are capable of evaluating the time when another malfunction will occur and how it will affect other parts. This means that the driver can be informed that one of the parts in a car might need maintenance and needs replacement or service.

Technology dedicated to predictive maintenance is linked to artificial intelligence and machine learning, and these are very efficient in monitoring battery life. That process could look like this.

These types of solutions are implemented in the logistic branch. I would encourage you to get yourself familiar with our article on that subject.

Automatic updates

Car applications nowadays are not a novelty. Not too many people are aware of the fact that most cars, similarly to TVs and phones have their own operating system that allows installation of additional software. IoT can provide tools to manage that software and automatically upload latest updates and revisions.

It is also worth mentioning that those updates can be followed by promotional campaigns that can have a great influence on the post-sales services revenue.

Code management

Do you know that the software of modern intelligent vehicles can have up to 10 million lines of code? This forces car manufacturers to maintain code repositories, monitor its readability and test coverage. Tools to monitor and report, provided by Internet of Things, can definitely be helpful with those tasks. In addition, integrations with other systems can allow users interested in such reports not to need to log in to multiple different systems. That is because IoT platforms can serve as aggregates for different kinds of data and allow role based access to specific information.

Summing up, we can boldly say that the presence of Internet of Things is now a reality. More and more car manufacturers are deciding to invest in IoT and implement solutions that solve one specific problem or help building the infrastructure that will pay off tomorrow.

Through the cooperation of IoT and automotive branch, we are observing constant increase of use cases and need for our solutions. The results of that trend benefit both branches, and its aftermath is an increase in the quality of manufactured products and services provided.

The automotive branch’s endeavor to implement newer technologies and latest solutions is starting to look more like a technological race. Advantages coming out of those implementations are visible in many different aspects of the industry and, to gain the edge on the market, all of them have to be maximized. The pace and quality of implemented changes will define the winners, so in order not to stay behind the pack, you need to be fast and start acting today.

Are you looking for an experienced company in the field of the Internet of Things? Contact us!