Product Lifecycle Management (PLM) is by no means a new concept, in fact it has been around since humans started producing things. However, PLM has a different meaning nowadays. Technological development has brought a revolutionary change, driven mainly by the current competitive market. There is a lot of pressure on manufacturers regarding time, quality, and innovation. Poor control of manufacturing processes can cost a company millions while achieving digital manufacturing maturity brings numerous business benefits

What is Product Lifecycle Management (PLM)?

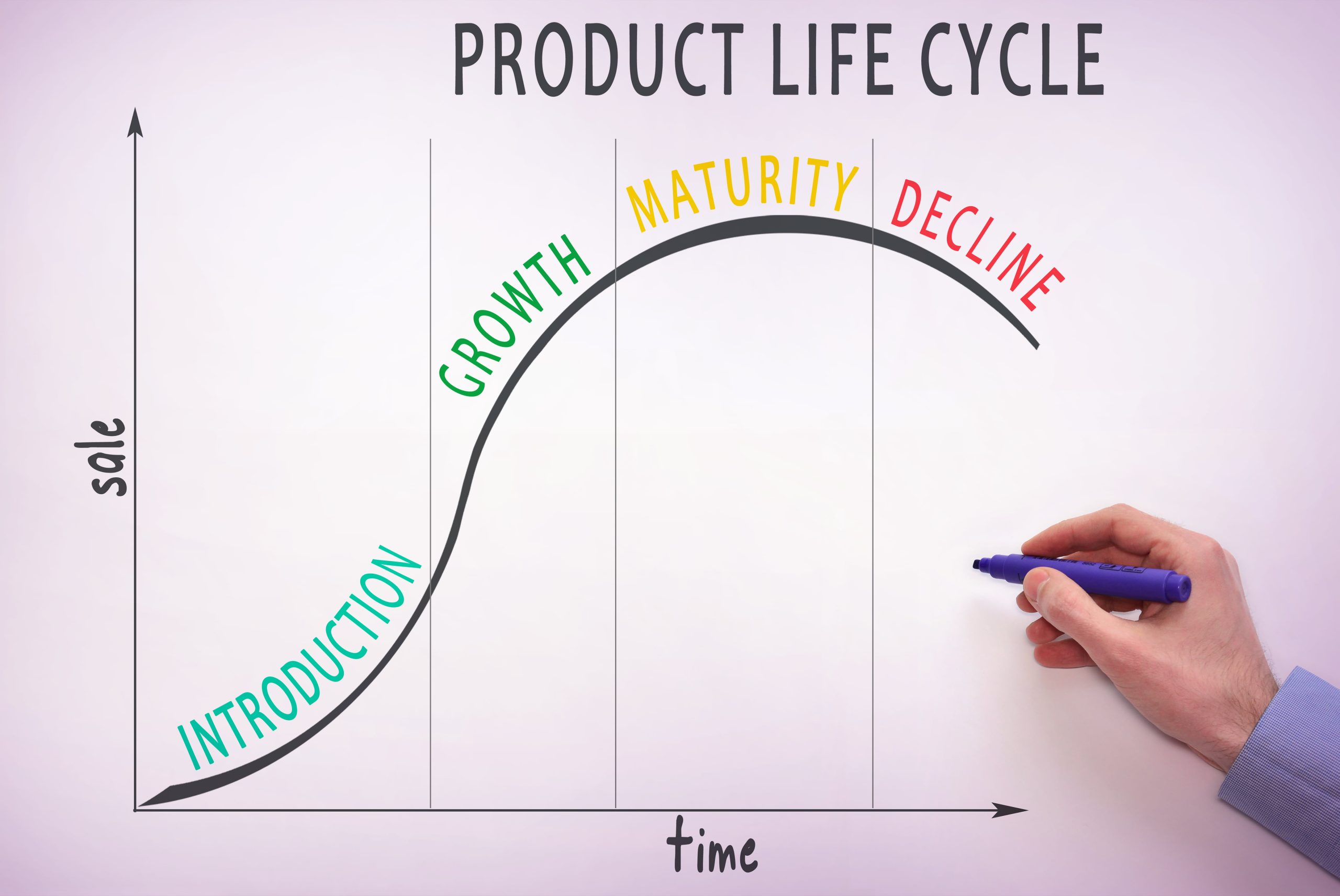

Product Lifecycle Management (PLM) is a strategy for managing a product through all its market lifecycle phases from introduction, through product maturity, to end-of-life. PLM can be described as a holistic approach to product development covering every aspect of the product lifecycle: innovation, requirements management, change management, or recycling.

Definition of a product

What is a product? Dictionaries say that a product is anything that can be offered on the market to satisfy demand. It can be either a physical thing, such as an item in a store, but also a service.

What is a product lifecycle?

The product lifecycle is about the process a product undergoes from the time it is introduced to the market until it is completely discontinued. The lifecycle is divided into four stages – introduction, growth, maturity, and end of life. Companies use PLC analysis (the process of studying the lifecycle of their products) to create strategies for maintaining product longevity or implementing change to meet market demand.

The role of PLM systems

A corporate PLM system is capable of integrating data, workflows, business systems, and people across an extended enterprise, facilitating the internal and external collaboration required by modern manufacturing environments. A PLM system is a reliable source of data that works to keep all stakeholders informed in real-time about emerging design changes. As an example, if an engineer makes a change to an engine head design, that modification can be seen by everyone associated with the project to ensure uniformity.

History of PLM

PLM was initially designed as a manufacturing and marketing tool for companies that sought to maximize the benefits of bringing new products to market. One of the first recorded uses of PLM was in 1985 by American Motors Corporation, which was looking for a way to accelerate the development process of the Jeep Grand Cherokee. Initially, the company focused on faster product development, so it implemented computer-aided design (CAD) software. The primary purpose of it was to increase the productivity of engineers. It then focused on a system to improve communication between stakeholders, which enabled faster problem-solving.

As a result, product data management became so efficient that the system scaled up and connected everyone involved in the design. Chrysler, which meanwhile acquired American Motors Corporation as an early adopter of PLM, became the lowest-cost automaker in the automotive industry. By the mid-1990s, it reported development costs that were half the industry average. The concept of managing the entire lifecycle of a product all the way from its development, through engineering design and manufacturing, to service and disposal of manufactured products, brought a whole new standard to the market.

Product lifecycle management – the benefits

By implementing PLM solutions, you can notice a reduction in bottlenecks in large organizations. Businesses achieve competitive advantage more easily while increasing customer satisfaction. The key benefits of PLM are:

- Reduced time to market

- Up-to-date product data stored in one place

- Driving innovation

- Cost reduction

- Product quality improvement

- Increased efficiency

- Reduction of bugs

Evolution of PLM

Nowadays, we are dealing with completely different PLM systems – more modern, integrated, end-to-end. However, there is one thing that remains the same. System PLM differs from other solutions because it focuses on gaining maximum revenue from recurring processes, thanks to their automation and equipping with advanced mechanisms of data collection and analysis. A properly configured, tested and implemented PLM system leads to innovation, dominance in the industry, and rapid growth. No other tool available on the market can match those capabilities.

PLM software for industrial companies

Currently, PLM is a field that covers the entire product lifecycle and crosses all areas of the enterprise: from requirements management to IoT data processing. It must address, for example, the information provided by the mechatronics department at each stage of the process and send lifecycle data back to the product engineering process. The concept of Digital Thread, which specifies the way to build the system environment of applications and systems used throughout the product lifecycle, is becoming increasingly important. Digital Thread provides a way to create a closed loop between the digital and physical worlds to optimize products, people, and processes. Today’s businesses are generating more data than ever before. And yet, for many organizations, effectively leveraging this data for digital transformation is still a major challenge. Therefore, the concept of Digital Thread is getting vital for successful organizational development and unlocking productivity growth.

The PLM market

The product lifecycle management software market was valued at USD 21.71 billion in 2020 and is expected to reach USD 32.42 billion by 2026. The demand for platform data analytics software in the industry is on the rise. These trends have been boosted by the increasing popularity of IoT in the manufacturing industry.

Source: https://www.mordorintelligence.com/industry-reports/product-lifecycle-management-software-market

Windchill – PLM system by PTC

There are many out-of-the-box solutions on the market provided by companies such as PTC, Siemens, Dassault System, Autodesk, and many others. Each of them has its own strengths and weaknesses. Since PLM concept covers the whole enterprise, using a good tool, tailored to specific needs, is crucial. It’s also important that all people (including engineers and managers) using the system are properly trained.

For years, the American company PTC has been a leader in the PLM solutions market. Windchill, their flagship system, tops industry rankings. This system is an instance of PLM software with built-in analytics for manufacturers looking for IoT solutions.

Transition Technologies PSC has been awarded Windchill Advanced Global System Integrator status in 2021. To qualify for the certification, partners must demonstrate individual and hands-on technical competence, solid customer references, and excellent satisfaction scores for their business and technical services.

Conclusion

To stay competitive, don’t underestimate PLM solutions. The key to success is to choose an experienced technology partner to help you figure out the right approach. If you found this article interesting and want to learn more about product lifecycle management, please feel free to contact us. We provide comprehensive PLM consulting services.