Following up our partnership with Rockwell Automation, our team of business and technical experts found their way to Munich, Germany to participate in TechED EMEA. It is a unique event during which you can listen, talk and test the latest news in the field of industrial automation and directly participate in the next industrial revolution.

Recent years and major strategic alliances in the field of Industrial Internet of Things have really accelerated the development and availability of solutions for companies that are ready to invest in their future. And that is exactly where we were – in the middle of everything, deepening our awareness and widening possibilities, expanding the frontiers of innovation. We have also collected some thoughts and observations that we’ll be happy to share with you.

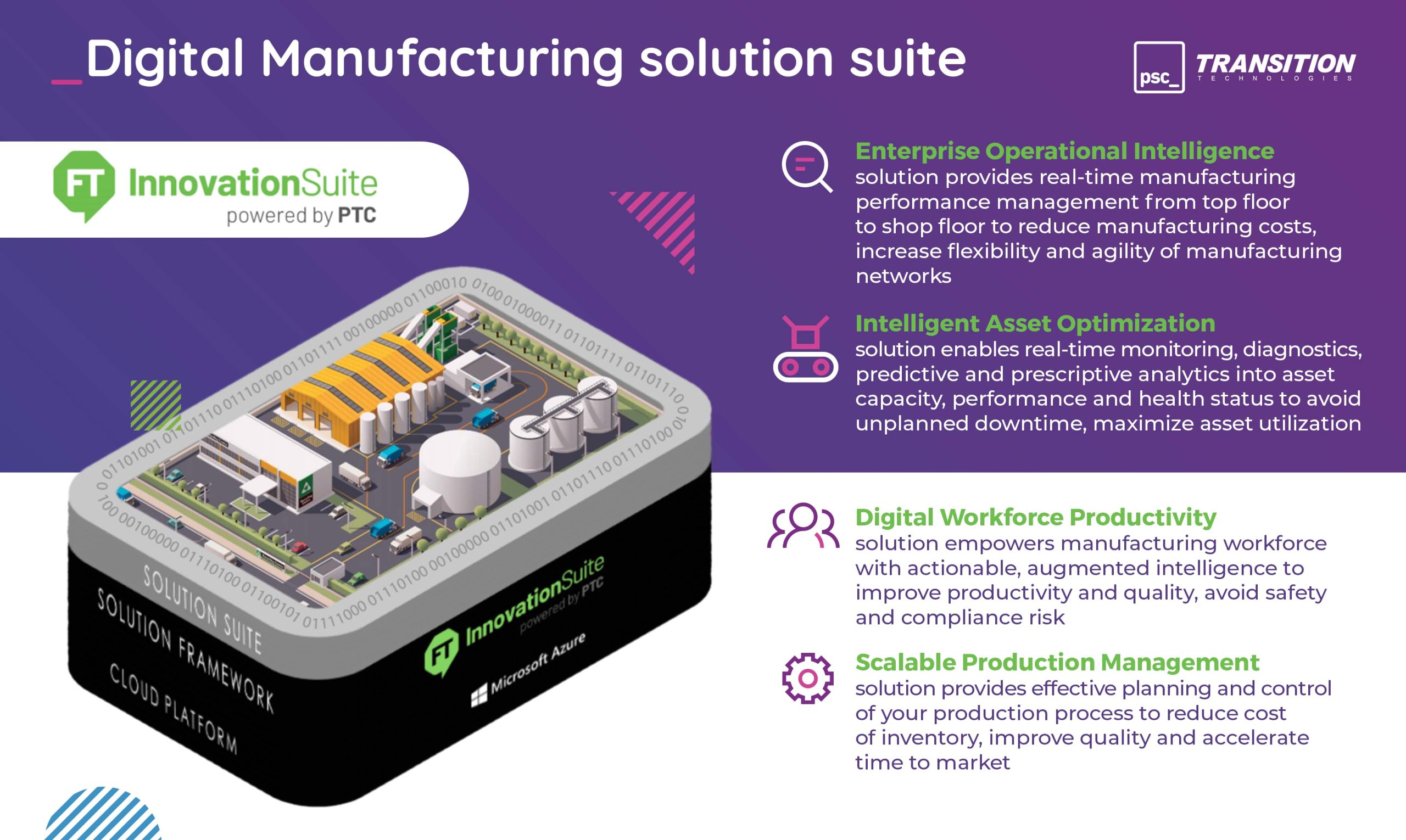

For obvious reasons, our attention was focused mainly on the latest breakthrough offer of the PTC-RA duo – FactoryTalk (FT) Innovation Suite powered by PTC. It connects two complementary worlds – IT and OT, obtaining the best. In today’s rapidly developing world, there is a need to take full advantage of every opportunity to optimize processes, reduce costs or facilitate work. Without this kind of competitive advantage, companies are lagging behind and are unable to meet the pressure and growing demands of the market. This is where FT Innovation Suite fits perfectly. Using the experience in the field of automation and software engineering, a whole set of complementary products has been proposed, setting a great example for IT / OT convergence. Because that’s the idea behind FT Innovation Suite – to get the necessary data and processes from the plant floor, from the IT systems and bring together all the data islands in one, optimized, connected solution.

What kind of areas, use cases are the easiest to find? As an example, you can give a couple of obvious ones:

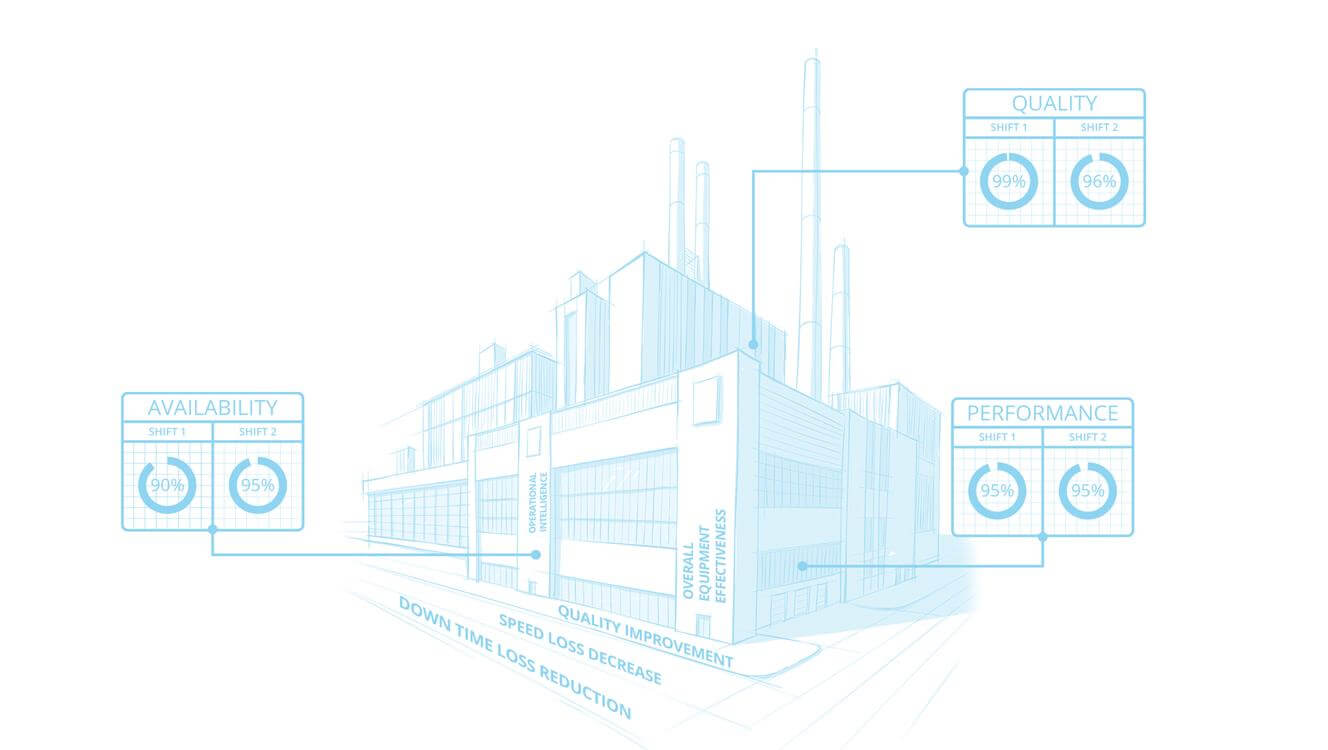

- Enterprise Operational Intelligence – to facilitate real-time visibility of manufacturing process, performance management, reduce costs and increase flexibility of manufacturing processes.

- Digital Workforce Productivity – to help plant-floor workers in everyday duties with augmented intelligence.

- Intelligent Asset Optimization – to support monitoring, diagnostic and analytics in order to avoid unexpected downtimes, plan and optimize maintenance and extend assets’ lifespan.

- Scalable Production Management – to provide control and planning to accelerate manufacturing processes.

One of the many very interesting elements of the FT Innovation Suite that caught my attention is Edge Analytics. Following the latest trends, it uses the edge computing concept to process and analyze data as close as possible to their place of origin, which drastically reduces the response time of an IoT solution to changing production conditions. Furthermore new industry standard it will be so called Fog (hybrid) solutions that allows maintain Intellectual Property on premise and securely transfer & process large neutral data sets in cloud. In this combination with intelligent devices on the one hand and a central analytical system on the other, it enables the full use of the power of data analysis to improve work and operations. And now, thanks to the integration of Rockwell Analytics Edge with the PTC ThingWorx IoT Platform, the use and sharing of this information is fastest possible for all users and processes involved in the digitalization.

In addition to all this, we also had the opportunity to participate in labs and demonstrations, being able to see the most interesting devices and software in action. It was a great experience.

What was additionally emphasized during the event is a huge value derived from partnerships, cooperation with other entities. In such a wide field, with a huge variety of devices, infrastructure, software and products – it is even more important to find the right partners specializing in specific solutions.

If you want to talk about similar topics, learn more or start cooperation – do not hesitate! We are happy to share our experiences.

But where there is hard work, there is also fascinating entertainment. Being in the Bavarian capital in October could not miss the traditional Oktoberfest – fun with music, good food and cold drinks. Thank you Rockwell Automation for this unforgettable experience.