How to increase production efficiency without investments in the shop floor?

You don’t have to replace your machines with the new ones to make your production „smarter” and more efficient. Your shop floor is a data mine, and digitization is the key to unlock its value. Technologies such as Industrial Internet of Things (IIoT), Artificial Intelligence (AI) or the public cloud are tools that allow you to collect and transform data into valuable insights, enabling you to improve production efficiency by identifying losses, minimizing production downtime or improving quality. Learn how technologies modernize manufacturing operations and maximize profits, turning even the most complex shop floor into a well-oiled… machine.

Optimize production through intelligent use of IT technology

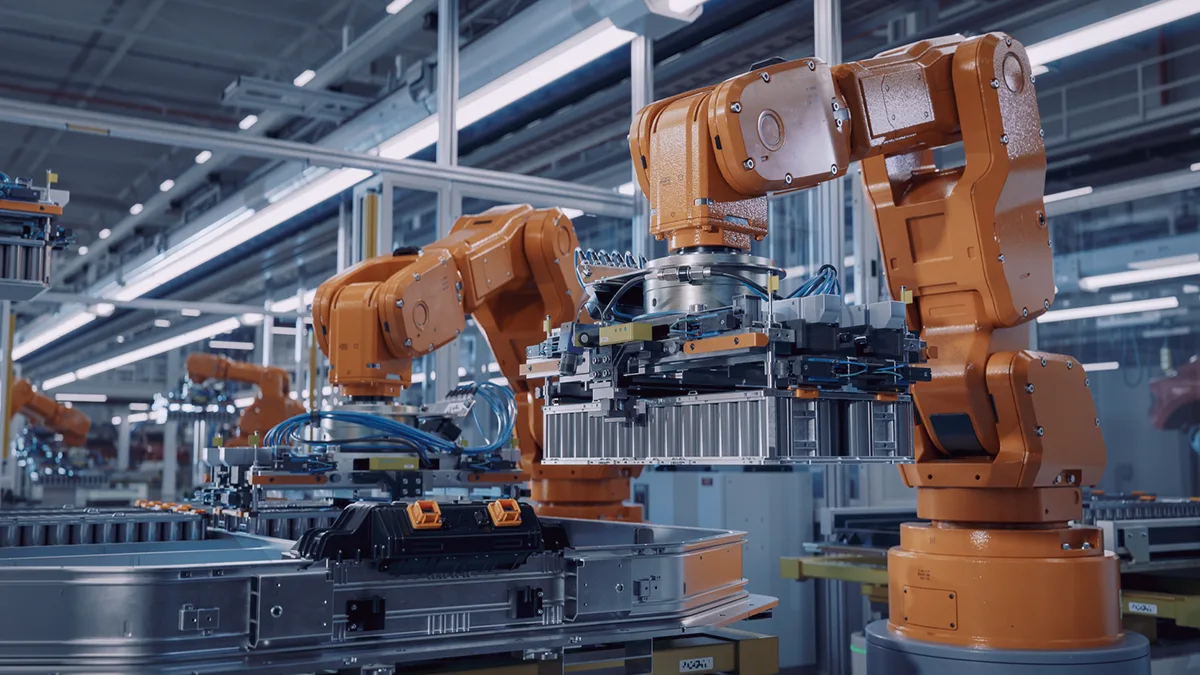

Manufacturers often face difficulties in achieving production goals, caused by the condition of machinery and equipment. Constantly improving shop floor, and expanding with modern robotic lines brings benefits…. Yes, this is true, but let’s consider whether a similar effect can be achieved in other ways, further reducing capital and operating expenses.

Effective utilization of the shop floor also includes the use of IT technology that allows precise tracking of production parameters, the quality of raw materials and input components, and the condition of machinery. On the basis of historical data correlated with current one, this allows to dynamically optimize and adjust the schedule or production parameters. This makes it possible to increase productivity, increase quality, and reduce material losses. The integration of machines with production management systems and process automation allows to increase in the resiliency and flexibility of plant operations, translating directly into its efficiency.

Consistent improvement, backed by smart technologies, allows manufacturers not only to avoid disruptions and achieve goals while minimizing resource consumption, but also to improve process efficiency. With flexible asset management, companies are countering production challenges by staying competitive.

Efficient shop floor and the role of production technologies

According to Deloitte: Technology will play a significant role in helping manufacturers address the challenges they may face in 2024. With their continued search for efficiencies, many intend to continue to meet their digital transformation goals.

In this context, it is worth considering what will be the competitiveness and efficiency of organizations that invest in innovative solutions in difficult times relative to those that do not.

A Deloitte survey found that as many as 86% of manufacturing executives surveyed believe that smart factory solutions will be the main drivers of competitiveness over the next five years. This is because increased organizational efficiency is needed precisely in moments of complex economic circumstances. This can determine the „to be or not to be” of a given company. It is worth emphasizing, however, that this is only the case when innovations are introduced with specific goals and expectations of return on investment (in the form of improved efficiency, increased capacity, and others) in mind. Finding the right technology partner can be helpful.

Monitoring of production efficiency

Automated data collection, especially with the calculation of the key operational efficiency indicators (such as OEE) based on it, is an indispensable first step in the digitization of manufacturing companies. While these are important tools – their true potential is only revealed through the effective use of this data. The collected data provides the foundation for optimizing production processes, predicting potential failures, and increasing efficiency, all made possible by suggestions generated by artificial intelligence (AI) and machine learning (ML).

Management of production becomes more transparent, enabling rapid response to changing conditions and dynamic adjustment of processes. Additionally, equipment utilization can be optimized when OEE data is interpreted by artificial intelligence systems in the context of production. By correlating OEE with other production data and parameters, such a system finds and recommends areas of improvement for more effective production management (it can, for example, detect anomalies in machine operation to predict breakdowns or recognize patterns to predict product quality).

In the context of the production shop floor, access to data makes it possible not only to monitor its operation but also to understand precisely its performance and potential areas of improvement. It can also be used to „make realistic” production targets or standard times (previously usually estimated).

Shop floor management

In addition, production flexibility becomes achievable through the use of collected data. Through AI/ML analysis, production plans and processes can be quickly adapted to changing market conditions. The combination of production machinery, data, and intelligent suggestions generated by digital technologies allows companies to achieve not only operational efficiency but also strategic flexibility in a dynamic industrial environment.

How does this work in practice? In the event of production disruptions (through equipment failure, unforeseen crew absence, or material delays), real-time monitoring allows you to immediately analyze the situation and propose solutions „on demand”, without waiting for the next shift or the next day. As a result, it can recommend dynamic changes to the production schedule, based on information about the efficiency of the line or shifts, the quality of delivered materials, or contractual requirements.

OEE production efficiency monitoring software

Production monitoring software is a fundamental part of the Industry 4.0 solution offering, defined as a system that enables managers, engineers (process, maintenance, or quality), and operators to analyze production in real-time. It provides comprehensive production data, such as the number of units produced, cycle time, time and reason for downtime, quality information, and energy consumption, which can be easily accessed at any time.

The software assists in maintaining production continuity. With precise data on machine uptime, downtime, or efficiency, operators can plan machine maintenance and repairs, minimizing the risk of breakdowns and downtime. This in turn translates into increased production efficiency and reduced equipment maintenance costs.

What does the implementation of an OEE system look like?

1) Data from machines and systems

The first step is to verify the machines, controllers (PLCs) and production support systems for the data they provide. Usually, it is possible to integrate with them, but sometimes it is required to buy licenses or add-on modules from the vendor. If the right signals are missing, additional sensors may need to be installed to fill in the missing data.

2) IIoT connectivity

The Industrial Internet of Things allows integration with machines and systems via industrial protocols, as well as the collection and transmission of data to business applications, including those for monitoring, measuring, and interpreting the efficiency of production resources.

3) Visualization and conclusions

The data is presented in a convenient and easy-to-understand form. Statistics and diagrams presented in the form of reports or user screens can be accessed via desktop, tablet, or even phone. These screens are available both to office workers who need them and on the production floor, where operators can record the causes of downtime and get real-time feedback on production performance.

Monitoring production is much more than calculating OEE

Typically, manufacturers proactively monitor several key performance indicators (KPIs) to understand how different functions are executing a specific process. Since each stage of production plays a specific role in a complex system, managers need to have quick access to information to understand how each part of the operation affects overall efficiency, where bottlenecks arise, and how they can be addressed.

KPIs, regularly monitored on the production panel, perfectly reflect this idea and represent best practices in managing production processes. Managers can keep track of key parameters in real-time, such as the number of units produced, cycle time, downtime, energy consumption, or productivity of individual machines.

In the context of modern manufacturing plants, specialized machinery, and innovative production, technologies play a key role in achieving set goals. Supported by advanced monitoring systems, modern machines allow precise control of production processes, which in turn translates into optimized efficiency. Common KPIs provide a unified view of the entire plant, integrating data from different sources and enabling managers to make good decisions.

Summary

The shop floor plays the role of the heart of any factory. However, optimizing production does not involve investing in new specialized machinery. The key to increasing process efficiency is the intelligent use of data and employee involvement.

The introduction of high-end machinery, tailored to the specifics of production, is one way to optimize the shop floor. Modern equipment with advanced functionalities makes it possible to obtain high-quality products while increasing productivity.

Digital transformation includes not only the introduction of new equipment but also a focus on the effective use of existing equipment, using available production data. Analysis of the collected information allows a better understanding of the production structure, identification of areas in need of optimization, and rapid response to changing market conditions. In this way, intelligent asset management becomes a key element of the strategy for achieving operational excellence.

We offer a full range of services for manufacturing companies, including:

– Advising on digitization roadmap and strategies to improve production efficiency.

– Return on investment (ROI) calculation

– Design, implementation, and integration of OEE applications with existing systems and infrastructure.

– Training, support, and service for OEE applications and production digitization.