The sudden epidemic of SARS-CoV-2 coronavirus and the COVID-19 disease has affected every sphere of the modern world. Caused by an epidemiological threat, the restriction of the flow of people, goods and services has already negatively affected the continuity of production processes in many industries, and each day this situation persists, without credible forecasts of a return to normality, will pull others into the spiral of detention threats. From day to day, in a very severe way, many factories have found that a rigid approach to competence management, warehouse management or renovation policy – when the access to staff and the supply of services and goods easily balances on the brink of disaster.

As humans, we will emerge from this epidemic with acquired resistance to viruses. But will the industry also become immune to unexpected isolation times? At Transition Technologies PSC, we believe we have a vaccine in the form of Industry 4.0 technology extract!

Effects of preventive anti-epidemiological isolation on the continuity of production

The restrictions imposed by governments on the flow of goods and services, together with the recommendation to avoid leaving the house and meeting larger groups of people, have had a fairly strong impact on the beaten routines regarding how production works. The events that have been counteracted by staff so far have suddenly become much more severe due to these restrictions. Especially noticeable this is in the few areas described below.

Staff availability problem

The recommendation to try to avoid gathering people in a small space has provoked many companies to reduce the number of staff present on the ground to the necessary minimum. The number of maintenance, management or even line operators has been minimized. Whoever could – have been directed to remote work. In the case of such a “skeletal” staff, any unforeseen problem or complication can lead to the retention of production due to a lack of knowledge or competence directly available. Unfortunately, working in such a mode brings a number of restrictions that, like the symptoms of the disease, interfere with the action of the body, which is the production plant.

These symptoms include:

- Limited maintenance staff reduce available expertise “at your fingertips”. If some experienced automation engineers, electricians, mechanics… is only on call time or supports only remotely – not all problems can be solved in a fast enough way.

- Remote work requires access to the system resources that are often available only locally or require client application installation and public internet access and authentication.

- Usually it is necessary to involve and cooperate with several people with different access and knowledge to collect data from different systems and sources into one report, which gives valuable information about the state of production.

- In a situation of concern for their own health and loved ones, employees often suddenly take leave, which makes it much more difficult to plan the occupancy of positions, machines and lines. Different employees have different levels of access, certificates, knowledge and experience – it’s hard to make the right shifts under time when you don’t see the entire image of available crew, orders, occupancy of people and machines.

Prescription:

- Augumented Reality experiences for interactive remote support based on space scanning using dedicated equipment, but also mobile phones or tablets – Vuforia Chalk.

- IoT system that integrates data from many systems and data sources to provide each employee – in a secure manner – with the right information on his home terminal (ordinary computer, telephone, tablet with browser) – ThingWorx Platform.

- Digital Twin – the state of machines and devices mapped in the digital domain to be able to diagnose and supervise operation without having physical access to the machine. Also notifications by email or SMS in the event of an anomaly in the operation of devices – ThingWorx Manufacturing Apps.

- A system supporting decisions on relocation of an employee to another production section based on certificates, experience, training, availability, performance and even preferences. Also supporting the implementation and assistance of a new employee with the use of Augmented Reality (AR) methods, or through dedicated, interactive job instructions – ThingWorx + TWX Operator Advisor + the Vuforia package (Expert Capture and Vuforia Studio).

Restrictions on the delivery of goods

Inactive distribution centers, limited supply of raw materials and components for production, suspended service visits or even completely closed borders for the flow of supplies can also cause disruptions in the functioning of the complex organism which is an industrial plant.

Symptoms of supply disruption include:

- Inability to carry out scheduled inspections, repairs, parts replacement. Machine downtime for repair purposes normally takes place according to calendar and are carefully planned taking into account many factors. What to do if, despite the planned renovation, no spare parts are available, or the service technician cannot arrive to the factory? Continue operation exposing yourself to a major malfunction and a much longer downtime or preventively shut down the machine while waiting for the nearest availability of a service technician?

- Warehouse space in today’s factories has often been kept to a minimum based on a proven supply chain and sub-supplier response time. How to choose what to order, what to produce, what to keep on shelves when it is difficult to predict potential supply problems.

The prescription for these symptoms may be:

- Instead of preventive replacement of parts in accordance with the repair calendar (Preventive Maintenenace), you can collect machine diagnostic signals or even sensor (excellent ratio of contribution to profit is brought by e.g. vibrodiagnostics) of the device and on this basis assess whether a given part really needs replacement or can still work for a certain time, because the manufacturer gave the date with a significant margin – ThingWorx with Manufacturing Apps.

- You can go even further and thanks to artificial intelligence to not only observe whether a given part is fully functional or is approaching its end of life, but even predict – on the basis of imperceptible for human analytical abilities, detectable for advanced algorithms of artificial intelligence – upcoming failures. Prescriptive Maintenance will allow you to predict failures in advance and adapt spare parts orders or maintenance downtime to it – ThingWorx Analytics

- However, if it is not possible to order a part, and we know that it is approaching the end of its life, then thanks to the same neural networks used for prescriptive repair activities, we can receive a recommendation that, e.g. reducing the speed of the line by 40% will extend the life of the part parts by 80%. Such analysis is extremely difficult, but with the use of artificial intelligence algorithms we will be able to do it and wait until the planned delivery of ordered spare parts – ThingWorx Analytics.

- However, if we need to turn off the machine, it is extremely important to determine how stopping this component of a production line will affect contractual obligations. Maybe in its place it is better to change another line to maintain the production of a key product from the point of view of contractual penalties, even at the expense of another. Such information can only be obtained by combining data from many sources, such as ordering, ERP, warehouse, MES and other systems (availability of employees, suppliers and recipients, accounting – to compare contractual penalties). These are difficult decisions designed to minimize the consequences of stopping production and a system that will be able to support such a decision by aggregating all the information affecting it is a great help for managers – ThingWorx.

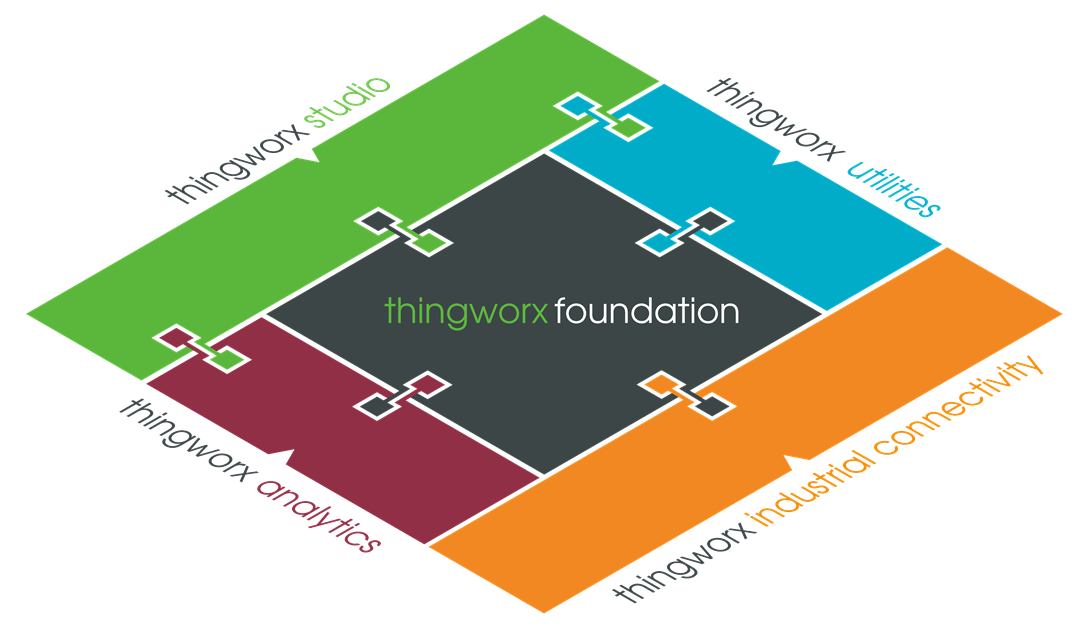

ThingWorx

ThingWorx is a platform, a framework for creating the Internet of Things systems and applications. Thanks to excellent cooperation with the modules responsible for data collection, their analysis and presentation in a friendly manner (remotely, according to the permissions granted, from a standard web browser), and even augmented reality tools – allows you to effectively use plant performance data, even if there is no physical access to the factory. Data from production and auxiliary machinery and equipment, as well as inventory and spare parts stocks, repair calendars, order list even with prioritization based on accounting and contractual data, to the availability of people – all through the ability to provide comprehensive data in the appropriate context which allows you to significantly improve the decision-making process. Never again will you need to create reports in Excel workbooks collected from many sources thanks to the expert knowledge of employees and at the expense of their valuable time. Once programmed, once learned, the system will collect the same data in real-time reports, according to given criteria.

To work correctly and provide such features, ThingWorx requires effective connection to many data sources containing info about operation of the plant. Integrations with these sources are facilitated by connector packages for communication with third-party software. The Industrial Connectivity (Kepware) package has over 150 drivers for machines, PLCs and SCADA systems, as well as implemented open communication protocols such as “Industry 4.0 language” – OPC UA ensuring secure transmission from any devices in the production hall. On the other hand, ThingWorx tools facilitate integration with management software such as ERP, MES, QMS, WMS and others even written for a specific function in a particular plant. Also the employee record system can be combined to automatically suggest a possible transfer of the employee in the event of unavailability to another line or machine, based on training, certificates or even preferences. In addition, it is possible to calculate automatically at the end of the shift whether the standard effectiveness has been achieved, whether the employee deserves a bonus or maybe he will need additional training to increase his efficiency. This allows you to react immediately to sudden, adverse and normally requiring a lot of effort from managers, events.

ThingWorx – Apps

The Manufacturing Apps package allows you to quickly build the presentation of data and methods of calculating production indicators that a specific plant requires. Adding new machines, organizing them in lines, setting the rules for alerting on measurement values or calculated values – including notification of specific people via email or SMS – all in a few clicks without entering the programming environment. Trends, emergency lists, machine lifelines, histogram, performance, quality, availability reports … all available in a short time after connecting the machine. Thanks to ThingWorx, you can also customize any part of the Manufacturing Apps package to adjust to the niche and unconventional requirements of a particular plant.

Operator Advisor as an addition to Manufacturing Apps will allow you to build screens contextually leading the operator “by the hand” through the activities that for this particular order, at this particular station are to be performed. It integrates data from the BOM, operating instructions, ordering system and sensor signals to guarantee a support of even a new employee in the production of high-quality products. By connecting to specific machines and devices, it can also automatically set intelligent screwdrivers, testers, packaging machines or print appropriate labels for a specific product and specific order.

Thingworx Analytics is a powerful Machine Learning tool that, thanks to modern artificial intelligence algorithms, will help you to draw more information from existing historical data. We will find correlations between the elements that have been omitted so far, which may affect the quality, production speed or frequency of failures. If we additionally monitor current data, the analytics system will allow to anticipate upcoming failures, recommend optimizations or even automatically take action. Therefore, seeing that the bearing with current operation will require replacement within a week – it can suggest changing the speed settings of the product through the line, and thus extend its life by another week.

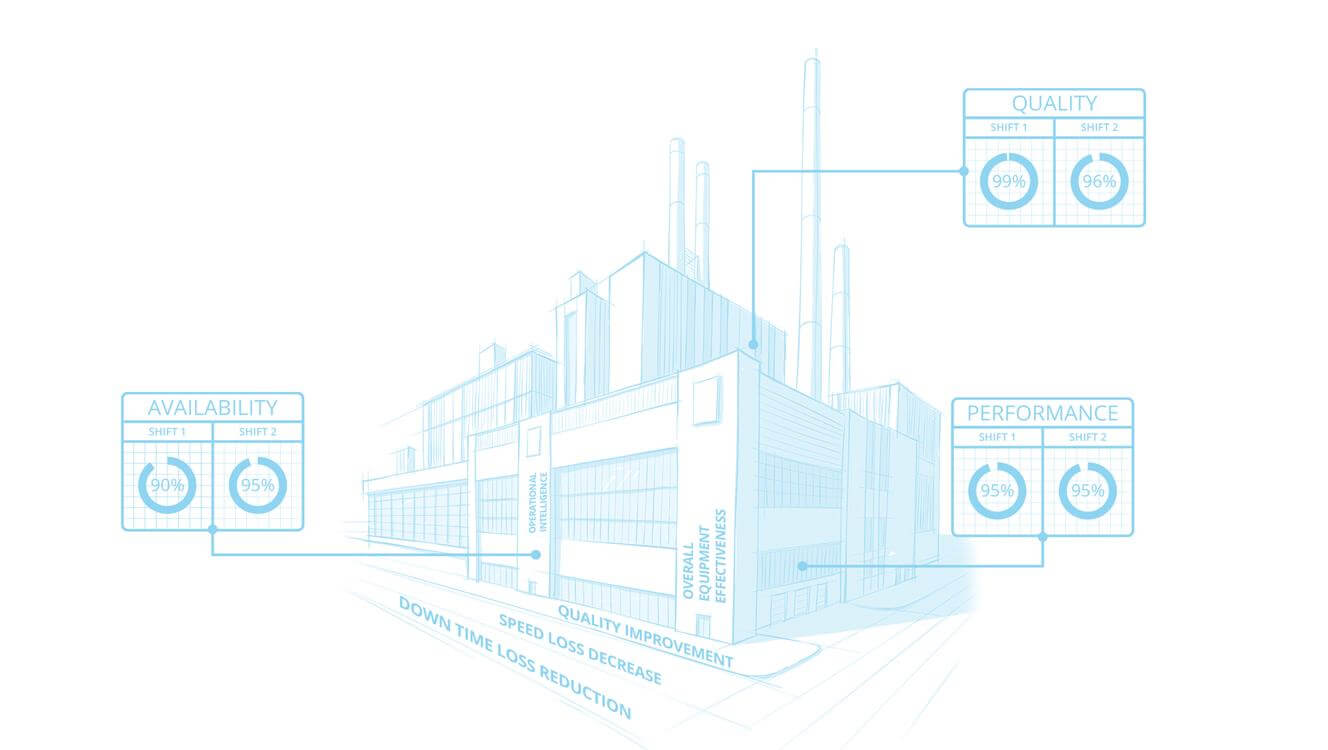

After the epidemiological crisis, when deliveries return to a safe standard, the Analytics system can, thanks to comprehensive analysis, recommend that accelerating production by 15%, will increase the percentage of damaged products, but will consequently increase OEE (Overall Equipment Efficiency), and therefore the profitability of production? Such analyzes require the comparison of many, sometimes seemingly uncorrelated data over a long time horizon and are difficult, burdensome and time consuming for the human mind (require normalization, purification and conditioning). Artificial intelligence is not bored, it is not mistaken (if we teach it correctly) and it never sleeps. Equally important, Analytics does not require the user to be familiar with the neural network architecture, which is the main Machine Learning algorithm. Moreover, it is extremely user-friendly and allows you to focus on analyzing the results, obtained in the light of domain knowledge possessed by operational experts. The result of such cooperation will not only help minimize the consequences of isolation in connection with the Coronavirus, but also optimize and improve the exploitation on a daily basis after the epidemiological threat has been resolved.

Having all the data about a specific machine, device or line, you can “build” so-called Digital Twin by setting up the right connections and context to the data (and even enriching with a virtual 3D model). Also known as the Digital Shadow, this construct is a mapping of the device parameters in the digital domain, so observing them will give us almost the same information that we would have had standing next to a physical machine. The maintenance engineer observing trends, mileages and alarm list will be able to see if the operation is going properly and if you need to contact the service giving them tips on work. As a last resort, you can even give it permission to turn off the machine or change its settings remotely.

Thanks to the Vuforia package, the digital image of such a Twin can be revealed on an appropriate scale on this engineer’s desk, which will help him understand the context of the observed data.

AR – Augumented Reality and Assisted Reality

The technologies previously known from Sci-Fi movies are here! You don’t have to wait for the brain interface to load expert knowledge directly into the mind. We already have tools that allow you to intuitively and quickly use the expert knowledge accumulated on servers, the cloud or directly, drawing from a physically located expert.

The time of isolation caused by the virus has highlighted what a problem can be the dispersion of knowledge and experience in the crew. When only a part of the maintenance team is on the shift, it may happen that a sudden problem with the machine occurs when no engineers who know it are in the plant. Or maybe the problem will occur at the weekend, on a holiday, at night … Then the phones usually warm up to red and even so often someone has to get in the car and “already” after an hour or two… appear on the spot because the green cable, button on the right, appropriate screw… apparently they were not exactly where the specialist remembered they are.

However, thanks to a modern tool from the Augmented Reality domain – the Vuforia Chalk package, this expert can look at the machine with his own eyes. Not only look (as this we can achieve also via a simple video conference) – it can also not only say what to do, but also draw on the screen tips for a person at the machine. These drawings: arrows, strokes, clouds – which is important – will not be only an ordinary trace always attached to the same place on the screen, but will be virtually applied to reality as well. If button No. 1 is outlined, even if the camera operator changes the viewing angle, distance, and even turns the camera’s eye for a moment – the outline will invariably point to the same button no. 1. All thanks to advanced space scanning and annotation as 3D objects in augmented reality. Sounds like Sci-Fi? And yet the future is now!

Not every task requires the support of a live expert. What are the instructions for? Bulky volumes of documentation, gigabytes of PDFs, countless pages full of electric cabinets. There, after all, every problem that can happen is described. That’s right – it will take a long, long time for an operator, maintenance engineer and service technician to find the required fragment. However, what if the correct instructions (e.g. for re-tuning, replacing the module, installing a new accessory) appear automatically in the actual context? This can be done based on Vuforia Studio. Importantly, these will not only be saved, interactive, context-specific instructions, but also a combination of real-time measurements.

Imagine that a new employee needs to replace accessory on the machine. He puts on holographic glasses or even looks through a tablet or cell phone and sees the procedure step by step. First step e.g. “return the machine arm to the starting position”. Until the machine registers the actual arm return, the next instruction step won’t be displayed.

Or maybe the ester must cool down? Until the temperature – which is displayed above the extruder – drops to a safe level, the operator will not know what to do next. No more damaged spindles, broken threads, burned service technicians. No more confused bolts, broken tabs – instructions on which elements and how to disassemble will appear, imposed on these elements, regardless of what angle the employee will be looking at. The elements on which the work is to be performed will illuminate, wring out, move, imposed exactly on their physical counterparts.

However, the work is not always so difficult that it requires a detailed instruction imposed on the object. Sometimes it is enough to make sure that the employee has carried out all the steps of the operation already known to him. He needs both hands to perform the activities, but also needs to confirm the steps taken, document the photo with a note, report to the warehouse, service and maintenance. Here, TT PSC can propose the Vuforia Studio application on the RealWear HMT-1 industrial portable device. It is worn on the head (attached to the helmet, cap, or directly on the head) – a kind of light tablet, whose small screen is built in such a way that without covering the line of sight allows you to look at it as if we had a 7 inch tablet in hand. This is called Assisted Reality. Dustproof, shockproof, with an easily replaceable battery with a capacity of 8h of continuous operation allows to be controlled by the voice even in a very loud environment. So without raising your voice you can confirm the implementation of the next steps of the displayed procedure or dictate notifications to the system, and the built-in camera allows you to confirm activities. All with both hands free.

The same tools can help to prepare training with an expert, which can be shown to every new employee or already trained as re-training. An expert whose time is valuable will not implement, train or instruct every new person how to carry out basic repair work. Instead, you can ask him to register a piece of his knowledge. However, it can’t be just a long movie, boring recording or kilometers of text. Vuforia Expert Capture comes to the rescue. A simple tool for recording and editing sequential instructions. It can be used with the camera on the phone or – preferably – a RealWear device. Then on the recording you can see both hands of an expert doing work from the perspective of his eyes, which will be most intuitively for the viewer of such a procedure. The next steps can be easily stopped, cut, add commentary, sequenced – all with voice commands! Without the skill of a cameraman or film editor, anyone can record a sequence from their perspective. Later edition, supplementation with additional steps, changing their order, updating, browsing through the list of steps, everything is so intuitive that it does not divert the attention of either the expert or the trainee from the merits. The above recipes are described in general although we know that every case, every bet is different and requires an individual approach, taking into account requirements and needs.

Therefore, before using… browse our website or consult our expert! We will be happy to help you immunize your workplace against complications similar to those that Coronavirus has set us now.